Metal sulfide film based on organic sulfur precursor and preparation method thereof

A metal sulfide and precursor technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems that hinder the expansion and development of ALD new metal sulfide methods, safety hazards, etc., and achieve excellent electroplating. Catalytic performance, reducing safety hazards, and the effect of dense and uniform crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

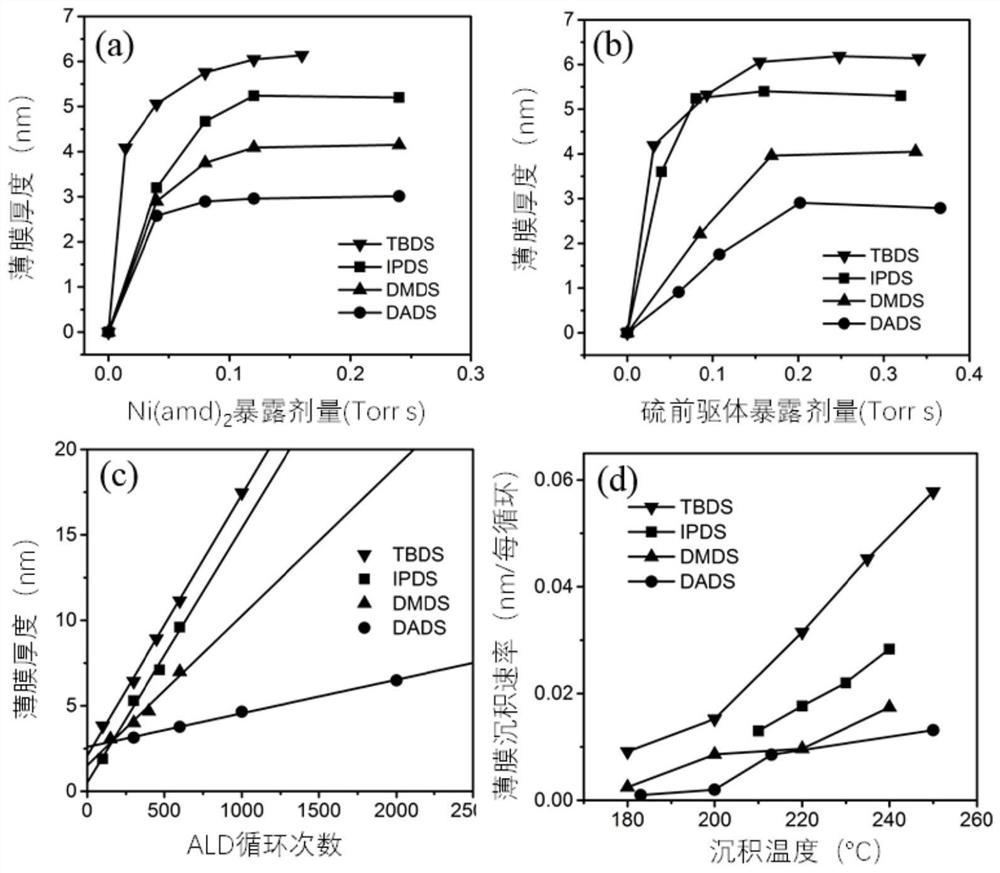

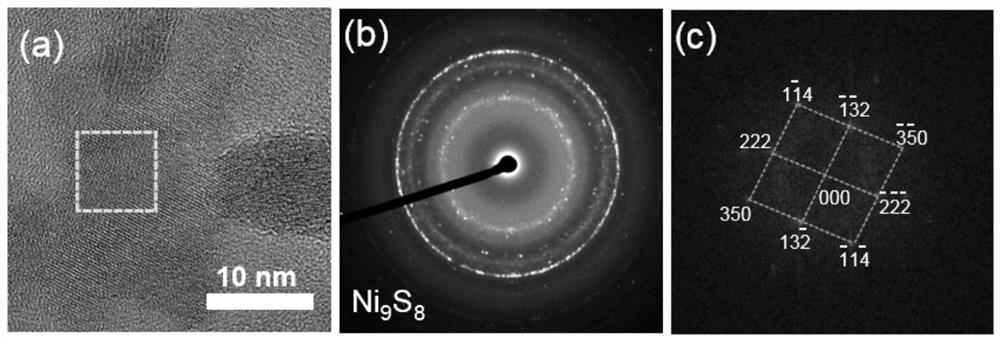

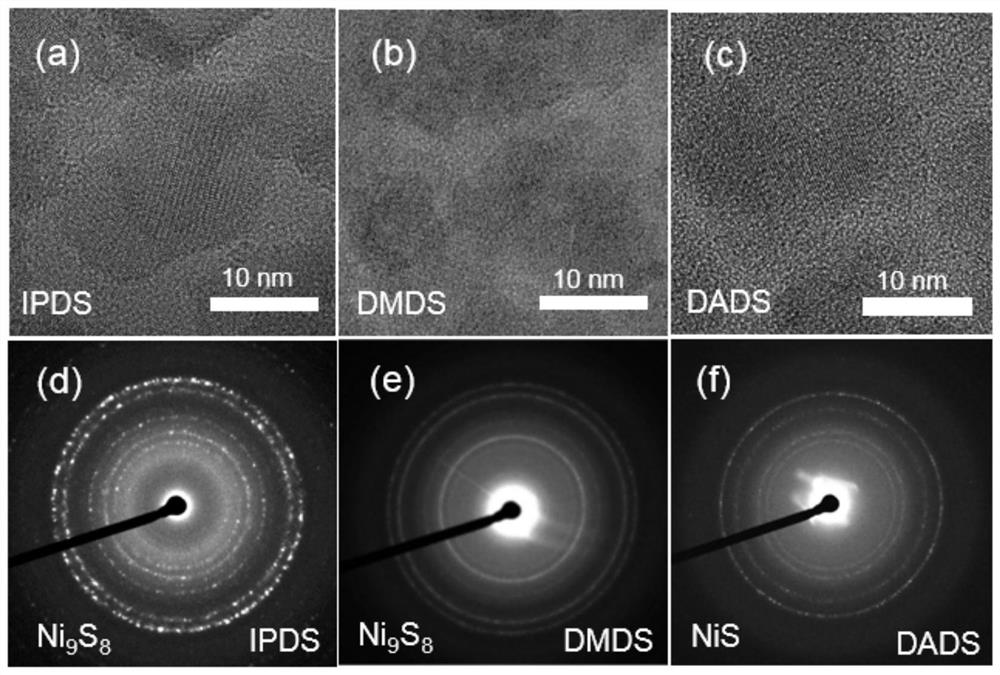

[0070] 1. Nickel sulfide (NiS) based on organosulfur precursors x ) film preparation.

[0071]Place the pretreated substrate in the ALD reaction chamber, control the temperature in the reaction chamber to 200 ° C, and bis(nitrogen, nitrogen-di-tert-butylacetamidine) nickel (Ni(amd) 2 ) is heated to 70°C to form bis(nitrogen, nitrogen-di-tert-butylacetamido) nickel vapor, in high-purity N 2 With the assistance of carrier gas, 0.12 Torr s of bis(nitrogen, nitrogen-di-tert-butylacetamido) nickel vapor was introduced into the ALD reaction chamber, and then N was introduced into the ALD reaction chamber. 2 Purge for 30s for the first time to remove unreacted bis(nitrogen, nitrogen-di-tert-butylacetamido)nickel precursor and reaction by-products, then heat the tert-butyl disulfide (TBDS) precursor to 35°C, The formed TBDS vapor was filled into the gas collector, and the TBDS vapor in the 0.15 Torr·s gas collector was introduced into the ALD reaction chamber in a pulsed manner. Th...

Embodiment 2

[0087] 1. Nickel sulfide (NiS) based on organosulfur precursors x ) thin film carbon cloth-based catalytic electrode (NiS x / CNT / CC) preparation.

[0088] Carbon nanotube / carbon cloth (CNT / CC) substrates were fabricated by drop-coating carbon nanotube (CNT) suspensions onto carbon cloth (CC). Deposition of NiS on CNT / CC with TBDS as organosulfur precursor x Film, its deposition method and parameters are the same as in Example 1, the difference is that the number of ALD cycles is 500 times, and the oxygen evolution reaction electrode obtained is expressed as NiS x / CNT / CC. For comparison, the NiS x The film is deposited on a pretreated flat glassy carbon electrode, and the prepared oxygen evolution reaction electrode is denoted as NiS x / GC, and with RuO 2 The suspension was drop-coated onto the pretreated glassy carbon electrode to prepare a standard catalyst electrode expressed as RuO 2 / GC.

[0089] 2. NiS x / CNT / CC Catalytic Electrode Characterization.

[0090] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap