Ocean windproof bridge support

A technology for bridge bearings and oceans, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of being easily damaged by blowing, tearing, performance degradation, and affecting the life of protection, etc., achieving remarkable windproof and dustproof sealing effects, durable Corrosion and aging resistance are excellent, and the effect of resisting typhoon force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

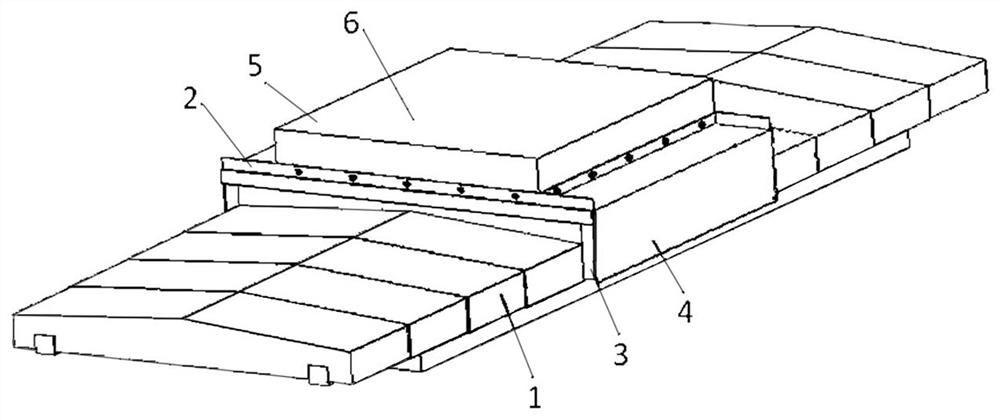

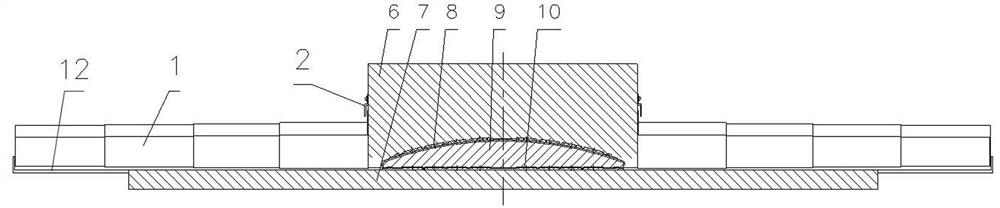

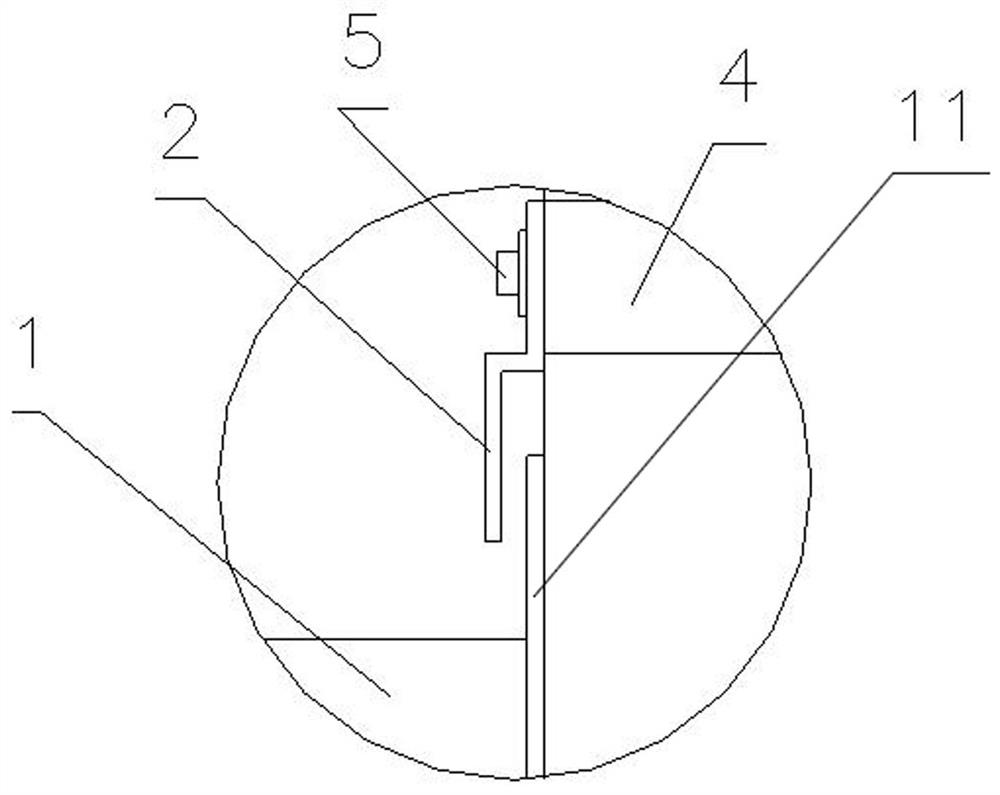

[0019] The present invention is described in conjunction with the accompanying drawings and specific embodiments of multidirectional movable marine windproof bridge supports, but the present invention is not limited to this embodiment, and can also be applied to longitudinally movable bridge supports, transversely movable bridge supports, fixed Bridge bearings and other types of bearings.

[0020] As shown in the figure, a marine windproof bridge bearing includes a bearing main body and a windproof mechanism; the bearing main body includes an upper seat plate 6, a middle seat plate 9, a lower seat plate 7, a plane friction pair 10 and a spherical surface The friction pair 8, the length of the lower seat plate 7 in the longitudinal bridge direction is longer than the length of the transverse bridge direction, which is convenient for the installation of the windproof mechanism. The lower surface of the seat plate 9 is a plane, and a plane friction pair 10 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com