Soil outlet beam plate structure by reversed construction method and construction method

A technology of beam-slab structure and construction method, which is applied in the direction of basic structure engineering, underwater structures, excavation, etc., can solve the problems of increasing the probability of water leakage, reducing the size of the excavation hole, and being easy to be damaged, so as to improve construction efficiency and increase Net size, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

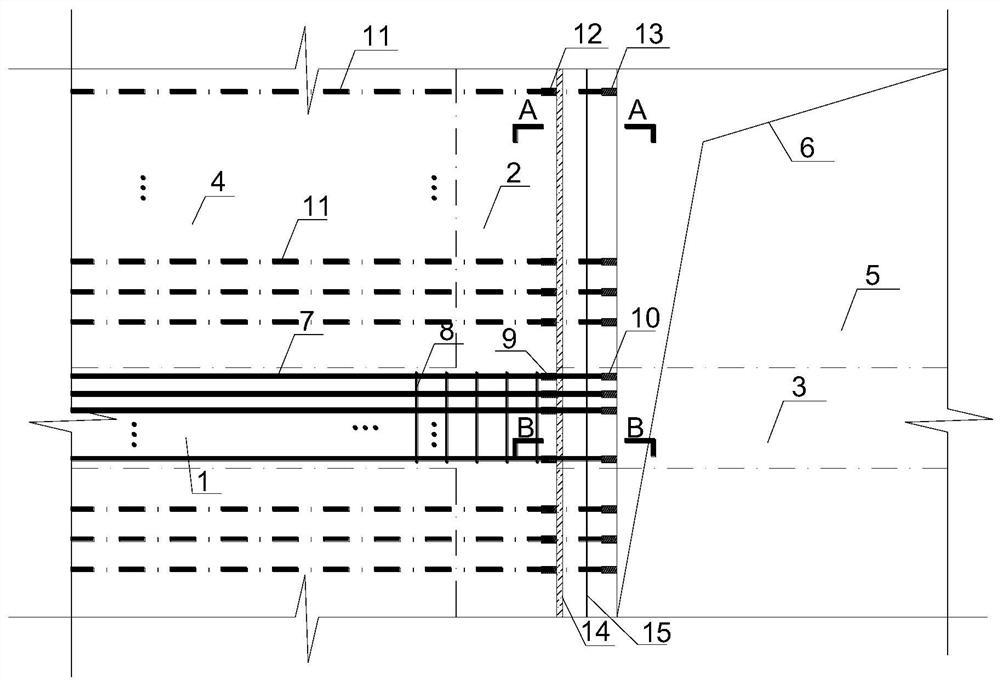

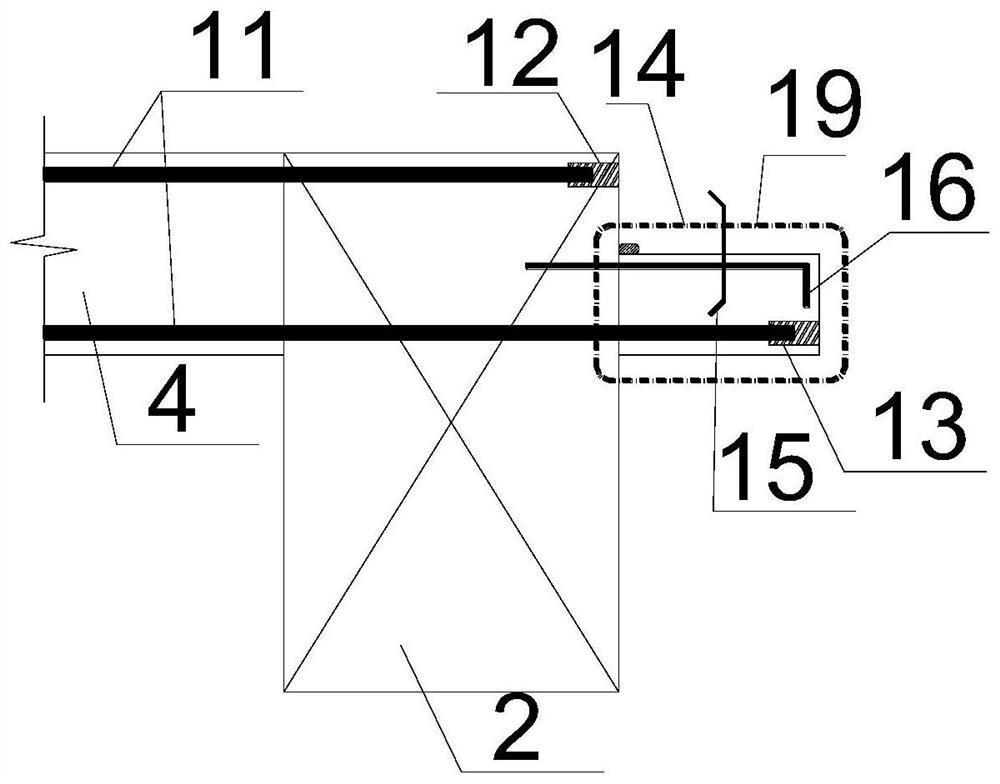

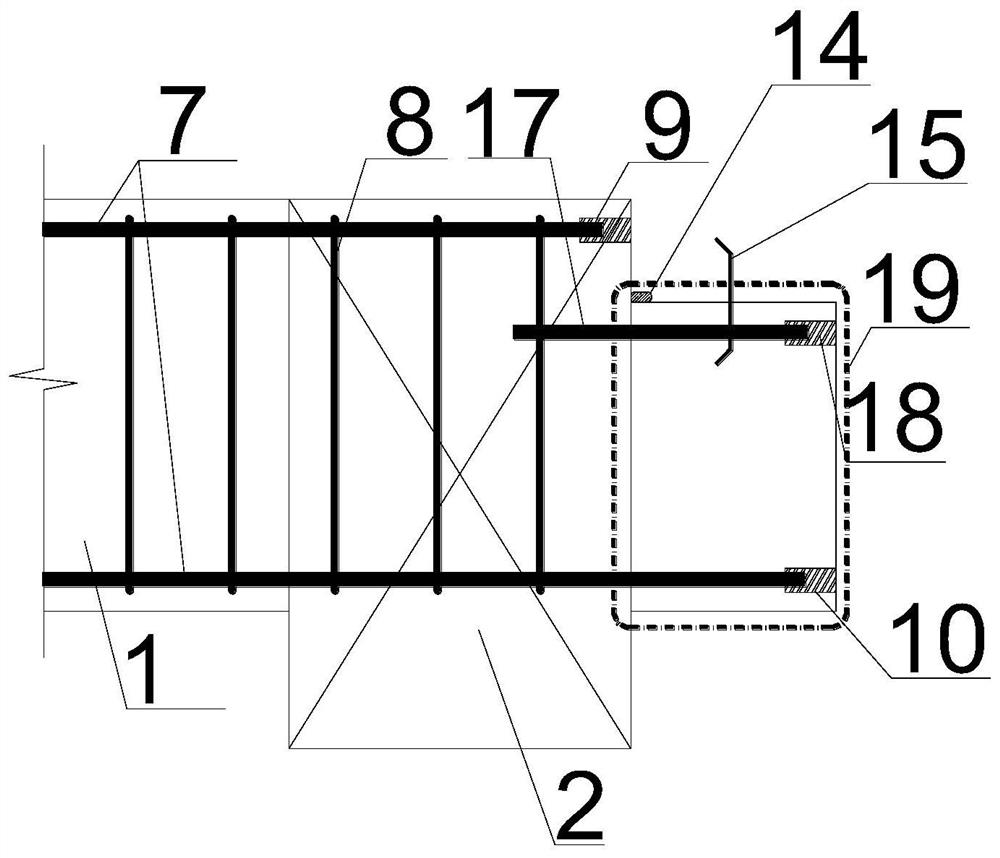

[0036] Combine below Figure 1 to Figure 5 , detailing the structural composition of the beam-slab structure of the excavation port by the reverse method of the present invention.

[0037] Please refer to Figure 1 to Figure 5, a beam-slab structure of the excavation mouth by the reverse method, including several pre-built components and post-construction components forming an integrated structure, the first-built components include the excavation mouth side beam 2, the first structural beam 1 passing through the excavation opening, and the first floor slab 4 The building components include structural beams 3 in the excavation opening and floor plates 5 in the excavation opening. The side beam 2 of the excavation opening is provided with a cantilevered member 19 near the unearthed opening, and a Z-shaped structure is formed between the side beam 2 of the excavation opening and the cantilevered member 19; The top of the cantilever member 19 is lowered by half the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com