Non-restraint connecting joint of support type damper and existing RC frame structure

A technology for frame structure and connecting nodes, which is applied in the direction of building components, building types, building structures, etc., can solve the problems of affecting the seismic performance of the structure, complicated construction operations, shear yielding of beam ends, etc. The effect of flexural/shear bearing capacity differential, reducing the effect of support energy dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

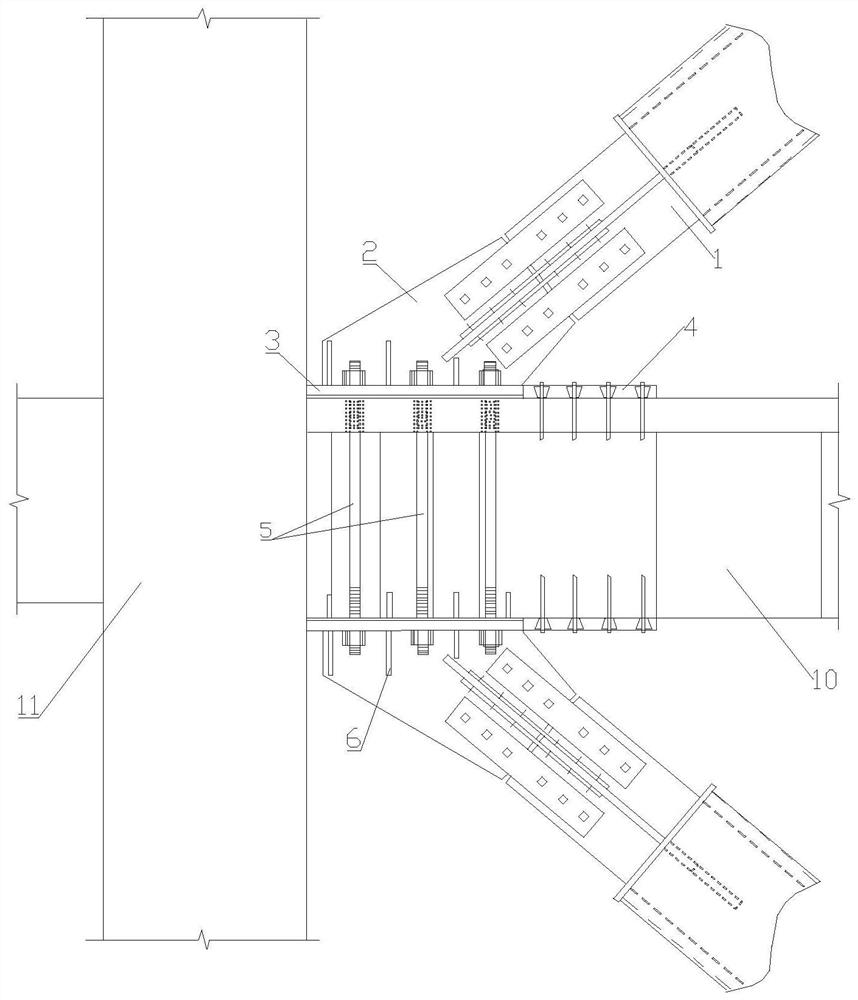

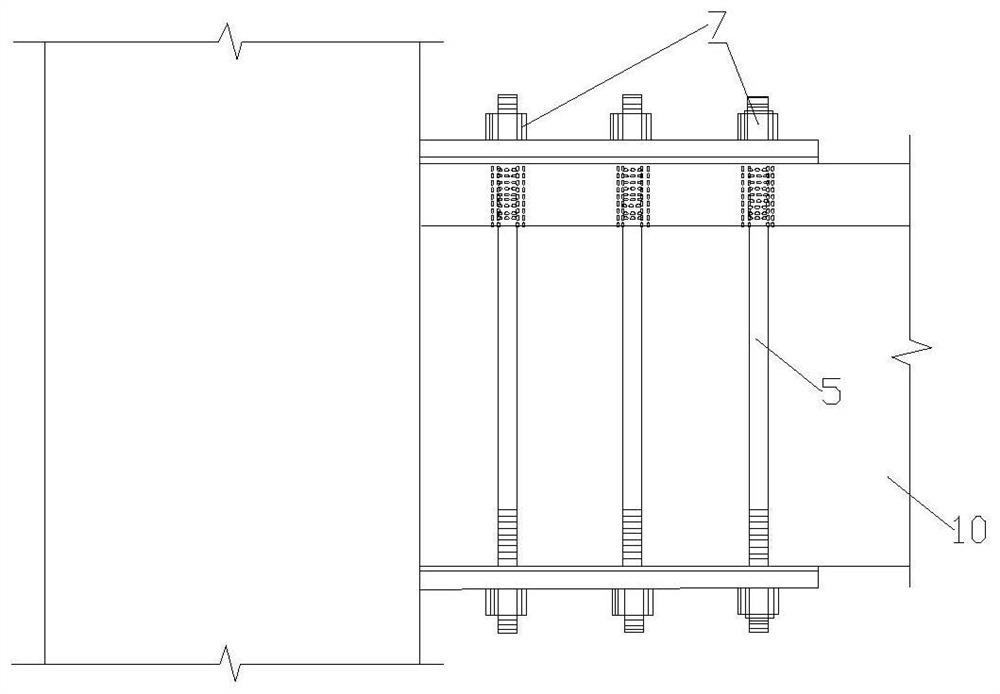

[0036] like figure 1 As shown, a kind of unconstrained connection node between a braced damper and an existing RC frame structure, including a braced damper 1, an unconstrained gusset plate 2, an end plate 3, a shear plate 4, and a tie rod 5;

[0037] Among them, one end of the unconstrained gusset plate 2 is connected to the beam 10 through the end plate 3, and the other end is connected to the support type damper 1;

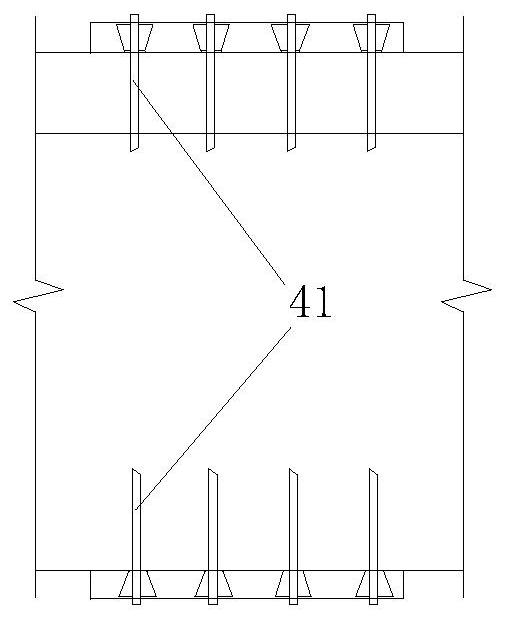

[0038] At the beam end node, in addition to being subjected to the bending moment, it is also subjected to a large axial force from the support, which is the key part of the force. The functions are partitioned to avoid the effect of short beams and short columns formed by the plastic hinge area at the beam end section. like Figure 5 As shown, the beam 10 is sequentially divided into a tensile functional area 101, a shear functional area 102, and an expected plastic hinge area 103 at the beam end from the end near the column to the end far away from the colu...

Embodiment 2

[0044] like Figure 7 As shown, when the span of the beam is small, the support damper can be arranged in the form of monoclinic support.

[0045] All the other are identical with embodiment 1.

Embodiment 3

[0047] like Figure 8 As shown, when the span of the beam is large, the support damper can be arranged in the form of herringbone + V-shaped support; furthermore, when it is arranged in the middle of the beam span, it is not necessary to adjust the load-carrying capacity level difference, and it is not necessary to carry out FRP reinforcement, that is, The end of the beam is reinforced with FRP, and the middle of the beam is reinforced with non-FRP.

[0048] All the other are identical with embodiment 1.

[0049] The non-constrained node connection method proposed by the present invention can effectively solve the influence of opening and closing on the beam-column and the gusset plate, avoiding the early exit of the support damper due to the fracture and failure of the gusset plate, and enabling the support damper to fully play The energy dissipation effect protects the main structure; the separate design of tensile and shear functions is realized by adding tie rods and shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com