Steel bar truss floor support plate and lap joint manner thereof

A steel truss and floor deck technology is applied in the field of reinforced truss floor decks and their lap jointing methods, which can solve the problems of long oblique bending, poor lap strength, and unsatisfactory sealing, and achieves increased or decreased strength and improved The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

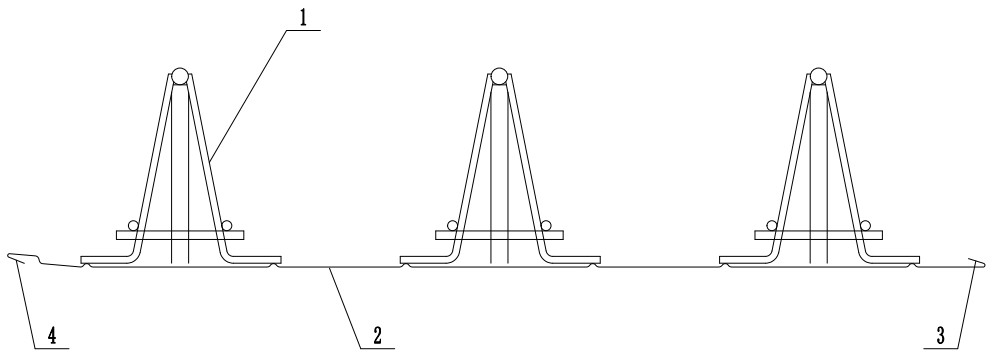

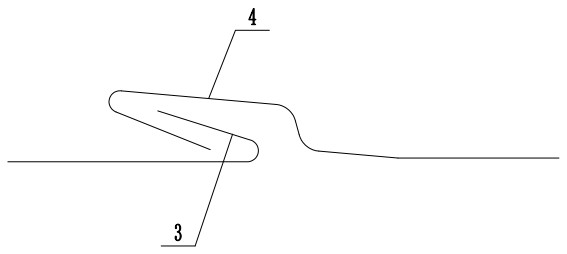

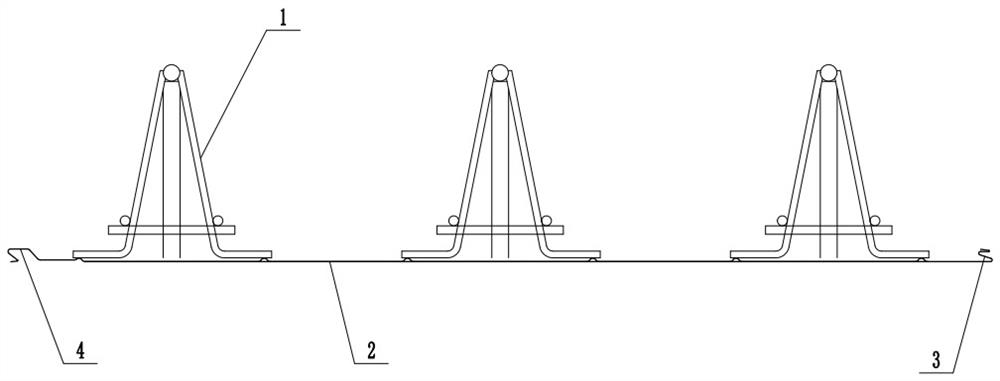

[0021] A steel bar truss floor deck, comprising a steel bar truss 1 and a bottom plate 2, the steel bar trusses 1 are evenly distributed on the bottom plate 2, and the two ends of the bottom plate 2 are respectively provided with lap lock tongues 3 and lap lock buckles 4 , the overlapping locking tongue 3 is formed by bending, and is in two consecutive U-shaped shapes, including an upper overlapping storage section 5 and a lower overlapping storage section 6, and the overlapping locking buckle 4 is formed by bending , including the locking section 7 , the upper closing section 8 , the side closing section 9 and the lower closing section 10 .

[0022] A method of overlapping steel truss floor decks. The bottom plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com