Electric control automatic gearbox

A technology of automatic transmission and transmission, applied in transmission control, one-way clutch, components with teeth, etc., can solve problems such as shifting stumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

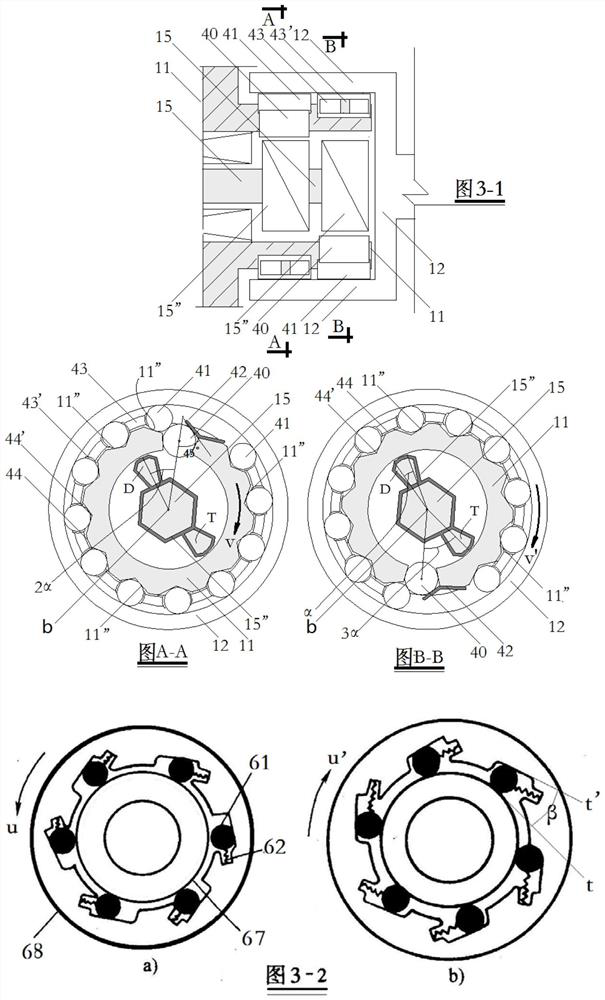

[0088] (1) Electronically controlled roller lock-up clutch

[0089] 1. Two-way electronically controlled roller lock-up clutch and its implementation

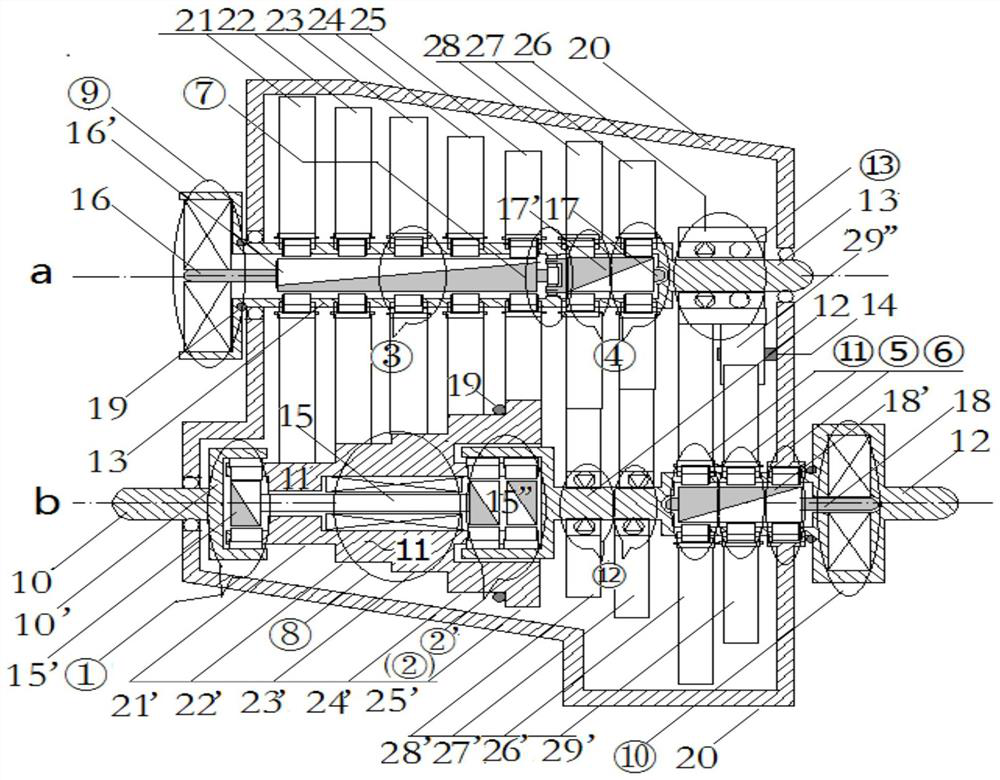

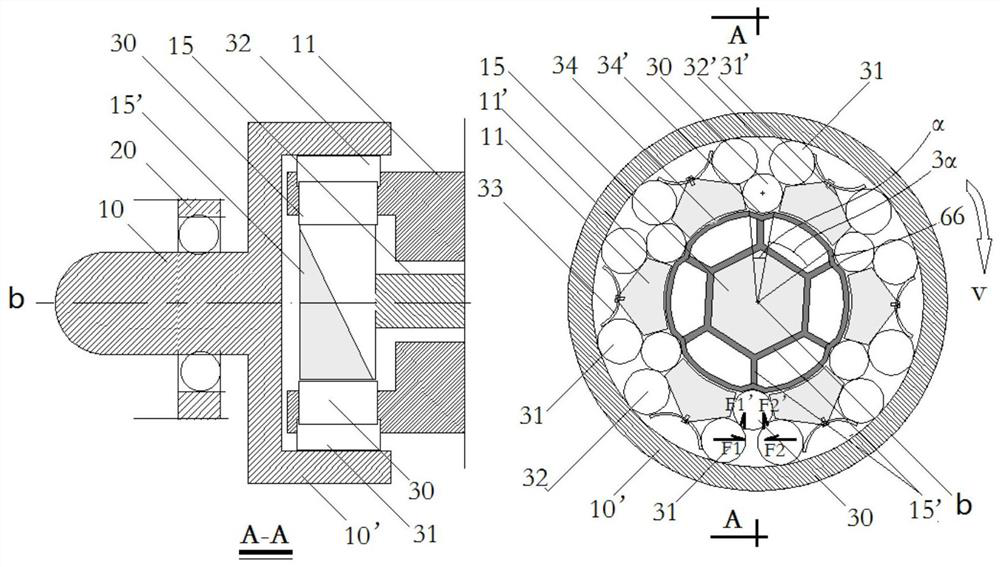

[0090] figure 1 Among them, ① and ⑥ on the b-axis are two-way electronically controlled roller lock-up clutches. Taking clutch ① as an example, the two-way electronically controlled roller lock-up clutch and its specific implementation are described.

[0091] figure 1 , figure 2 Shown, the gearbox input shaft 10 and the sleeve shaft 10' are consolidated; the tower gear shaft 11 and the sleeve shaft 10' are the inner and outer rings of the electronically controlled roller lock-up clutch ①, that is, the two transmission parts of the clutch ①. Depend on figure 2 It can be seen that the two-way electronically controlled roller lock-up clutch ① consists of the outer ring 10', the inner ring 11, the lock rollers 31, 32 placed on the lock ramps 31', 32', and the rollers 31, 32 The tangential forced roller 30 and the locking ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com