Efficient and environment-friendly industrial waste gas treatment and purification equipment

A technology for industrial waste gas and purification equipment, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of increasing the hidden danger of RTO purification equipment explosion, explosion of RTO purification equipment, accumulation of organic waste gas, etc., to save resources, Effect of improving mixing degree and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

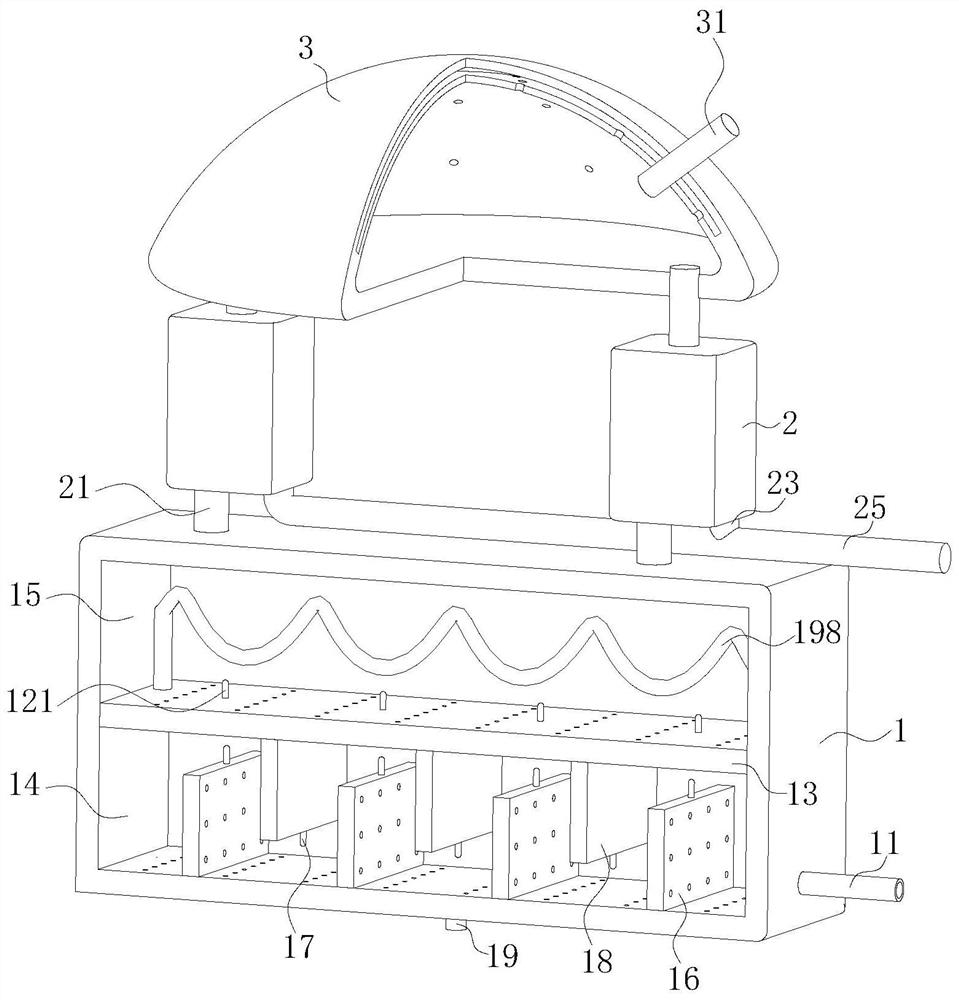

Image

Examples

Embodiment approach

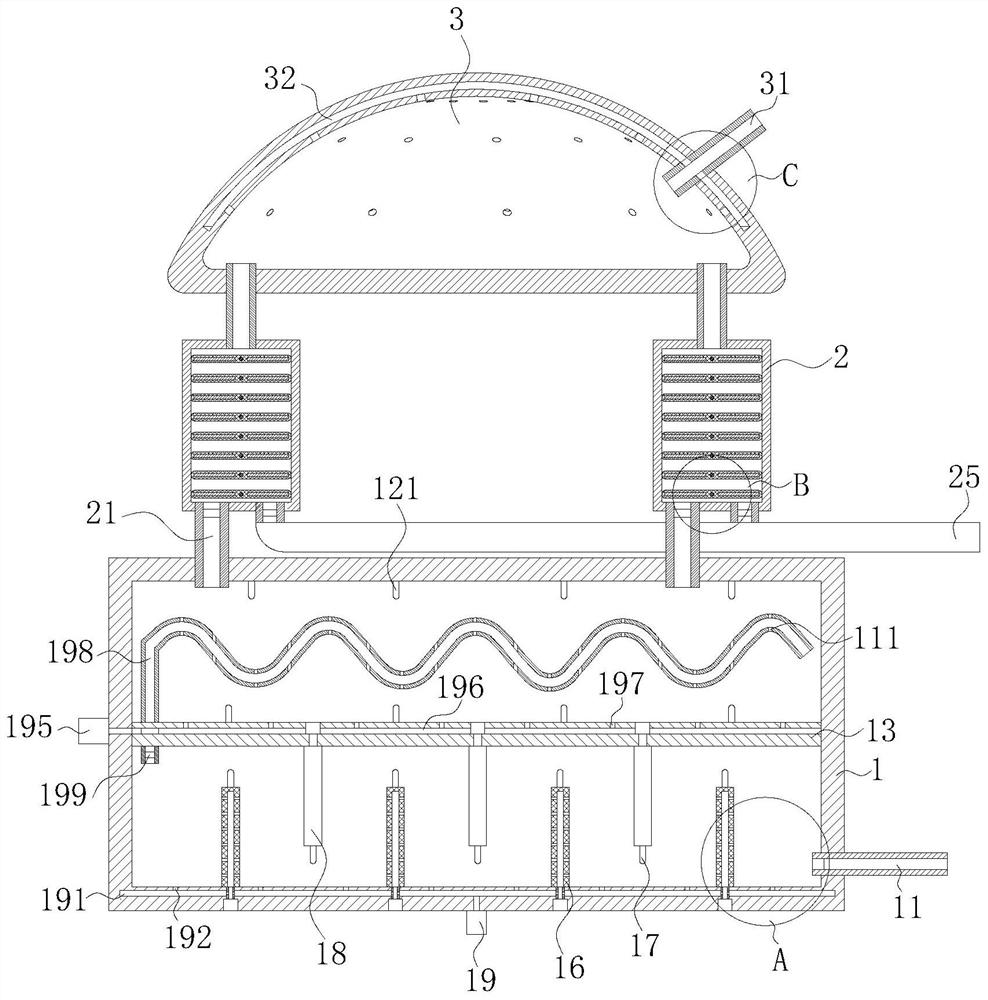

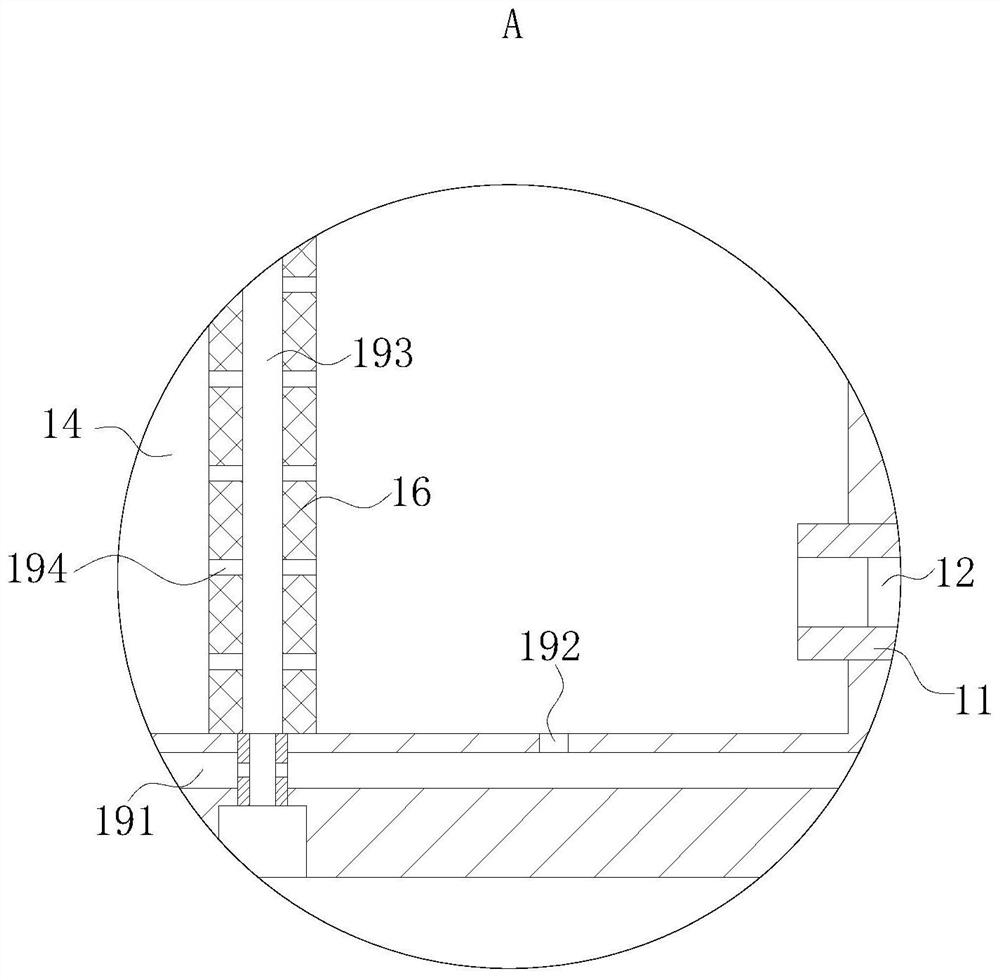

[0035] As an embodiment of the present invention, a second air pump 195 is fixedly connected to the left end surface of the detection box 1; a third air groove 196 is opened in the inner wall of the baffle plate 13, and the third air groove 196 is connected to the first The two air pumps 195 are in communication; the inner wall of the third air groove 196 is provided with uniformly arranged second through holes 197, and the second through holes 197 are all in communication with the upper cavity 15;

[0036] During work, since the third air groove 196 provided in the inner wall of the baffle plate 13 communicates with the second air pump 195, when the second concentration detector 121 detects that the concentration of the organic gas in the upper chamber 15 is too high, the controller will Control the operation of the second air pump 195. During the working process of the second air pump 195, the outside air can be sucked into the third air groove 196. When the gas flows into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com