Gas relay with independent heavy gas and oil loss functions

A gas relay and gas technology, applied in the direction of fluid velocity measurement, by detecting the dynamic effect of fluid flow, instruments, etc., can solve the problem of inability to accurately judge heavy gas oil flow, reduce the frequency of manual inspections, and improve the accuracy of monitoring faults , the effect of reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

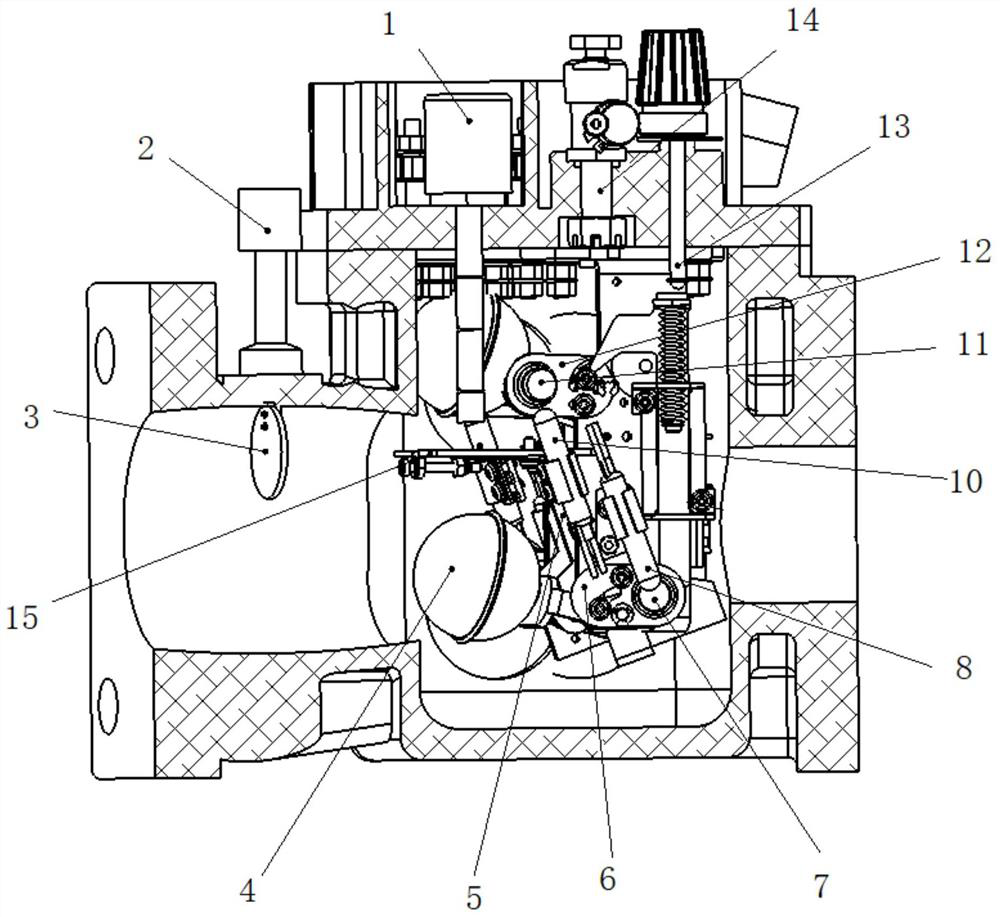

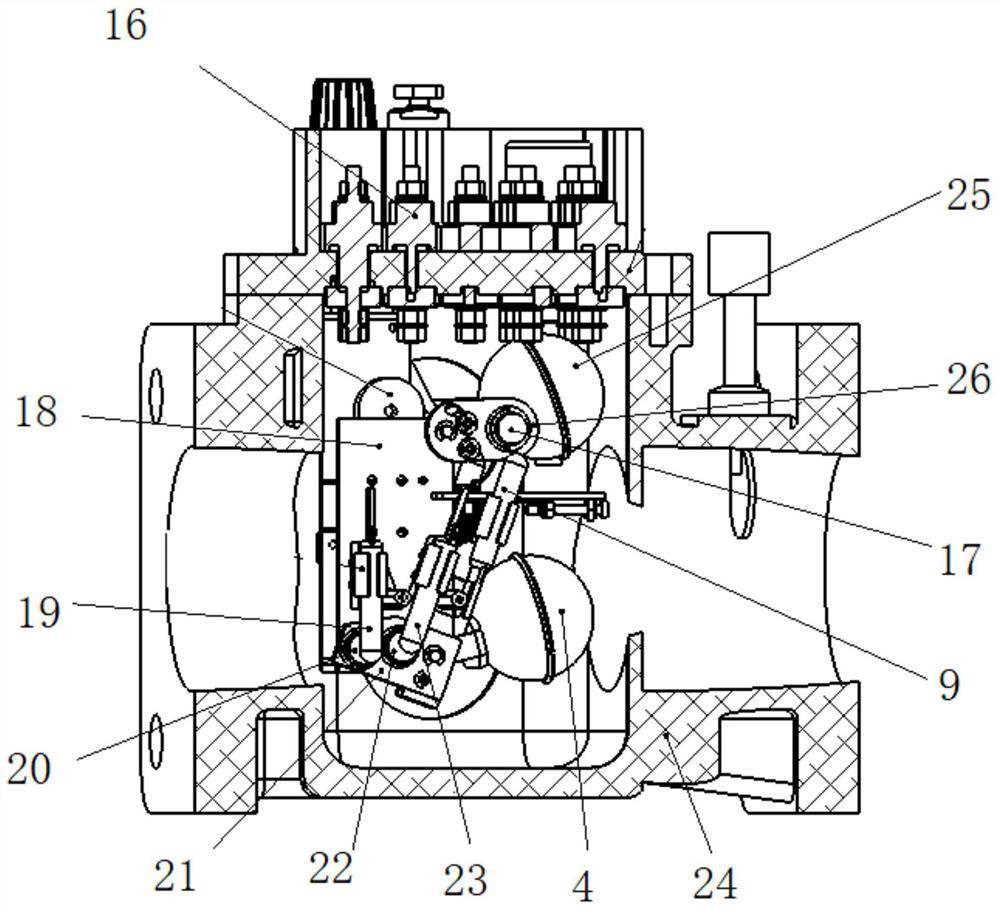

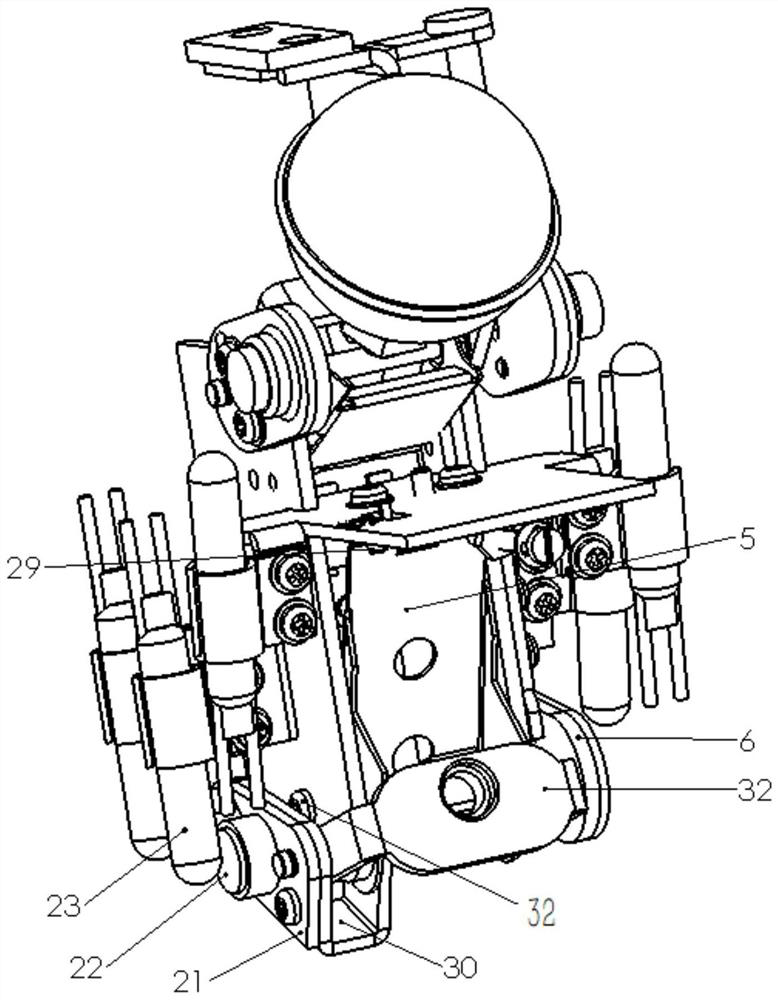

[0033] Such as Figure 1-Figure 4 As shown, the gas relay with independent heavy gas and oil loss functions includes a housing 24, which is equipped with light gas functional components, heavy gas functional components, oil loss functional components and a monitoring system. The following describes each component in detail.

[0034] The heavy gas functional assembly includes a baffle plate 5, a heavy gas magnet seat, and a heavy gas reed switch. There are two heavy gas reed switches, respectively denoted as the first heavy gas reed switch 19 and the second heavy gas reed switch 23. The heavy gas magnet seat is provided with heavy gas magnets, which are respectively recorded as the first heavy gas magnet 20 and the second heavy gas magnet 22, corresponding to the first heavy gas reed switch 19 and the second heavy gas reed switch 23 one by one. The number of groups of heavy gas magnet holder and heavy gas reed switch can also be set to one or three groups, etc., depending on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com