Pixel arrangement structure and display panel

A technology of pixel arrangement and array structure, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reducing the ink deposition area, reducing the light-emitting area, and affecting the resolution of the display panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] A method for preparing a display panel according to another embodiment of the present invention includes the following steps:

[0062] S101: Provide a substrate.

[0063] The driving circuit array can be fabricated on the substrate through the yellow light process.

[0064] S102: Fabricate patterned pixel electrodes in each light emitting region of the substrate.

[0065] A planarization layer may also be formed in the light emitting region of the substrate where the pixel electrode is formed. By forming a flat layer, the uneven surface caused by the driving circuit can be covered, which is beneficial to the formation of subsequent layers. The planar layer can be made of organic materials and prepared by inkjet printing, which is not particularly limited here.

[0066] S103: Fabricate a pixel defining layer in the light-emitting region of the substrate, and define several pixel pits to form a light-emitting region and a light-transmitting region corresponding to the ...

Embodiment 1

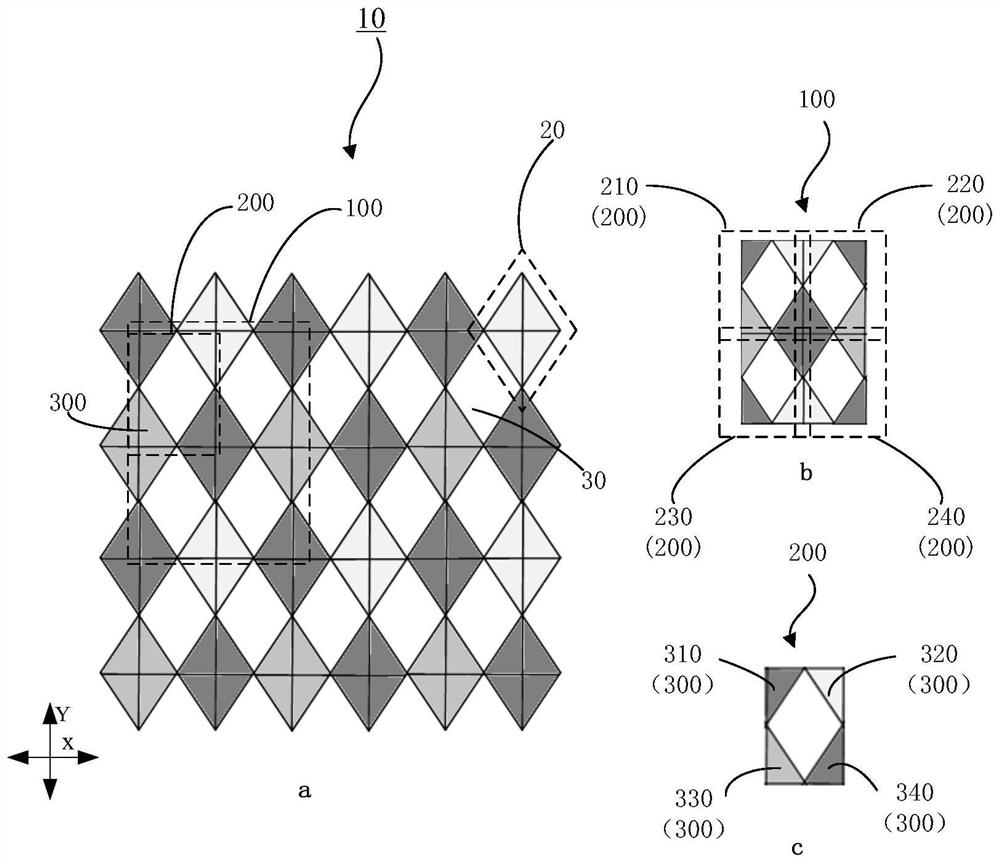

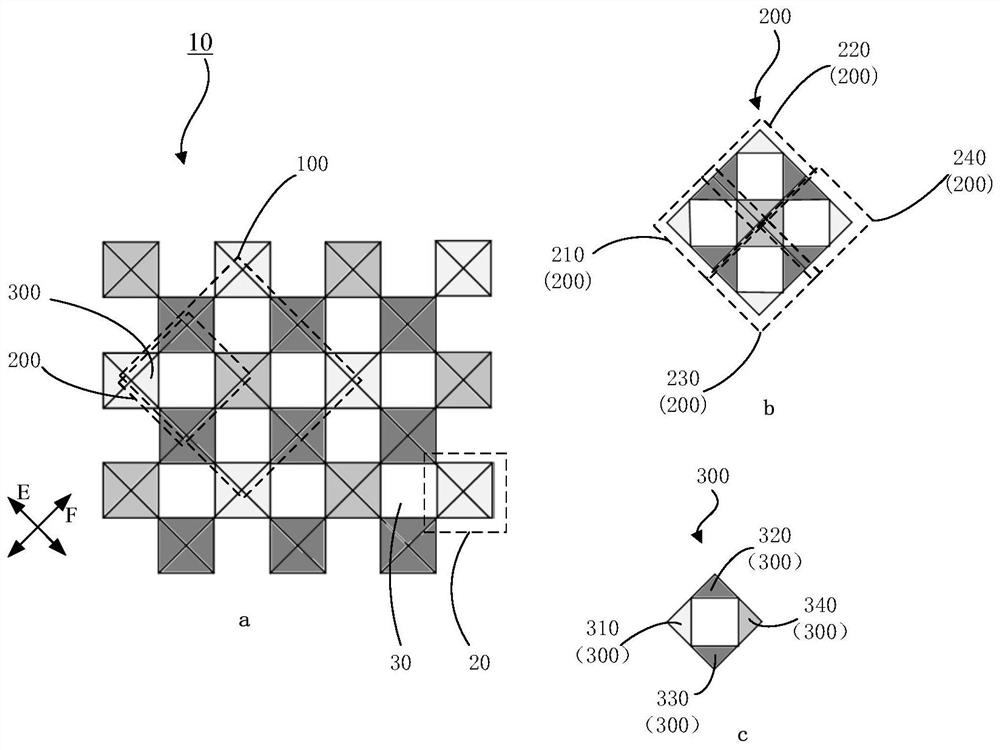

[0075] Such as figure 1 As shown, the pixel arrangement structure 10 of this embodiment includes a plurality of repeating units 100, and the repeating units 100 are arranged along the row direction and the column direction ( figure 1 In the X direction and the Y direction, X and Y are perpendicular to each other), forming an array structure; the repeating unit 100 is divided into four pixel units 200 of 2×2 along the row direction and the column direction, which are respectively the first pixel unit 210 and the second pixel unit 210 unit 220, the third pixel unit 230 and the fourth pixel unit 240, the first pixel unit 210 and the fourth pixel unit 240 are centrally symmetrical, the second pixel unit 220 and the third pixel unit 230 are centrally symmetrical, and the first pixel unit 210 . The center of symmetry of the fourth pixel unit 240 coincides with the centers of symmetry of the second pixel unit 220 and the third pixel unit 230 .

[0076] Each pixel unit 200 includes f...

Embodiment 2

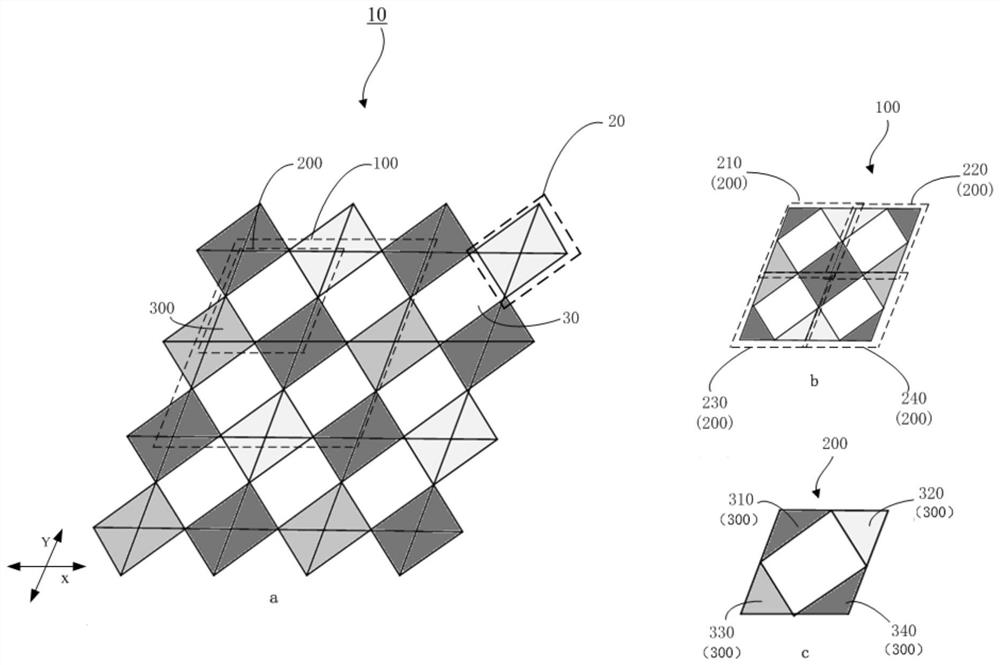

[0079] Such as figure 2 As shown, the pixel arrangement structure 10 of this embodiment includes a plurality of repeating units 100, and the repeating units 100 are arranged along the row direction and the column direction ( figure 1 In the X direction and Y direction, X and Y have a certain angle), forming an array structure; the repeating unit 100 is divided into four pixel units 200 of 2×2 along the row direction and the column direction, which are the first pixel unit 210, the second pixel unit 200, respectively. The second pixel unit 220, the third pixel unit 230 and the fourth pixel unit 240, the first pixel unit 210 and the fourth pixel unit 240 are centrally symmetrical, the second pixel unit 220 and the third pixel unit 230 are centrally symmetrical, and the first The symmetry centers of the pixel unit 210 and the fourth pixel unit 240 coincide with the symmetry centers of the second pixel unit 220 and the third pixel unit 230 .

[0080] Each pixel unit 200 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com