Magnetic drive plane rotary screen

A plane rotary sieve, magnetic drive technology, applied in sieves, solid separation, separation of solids from solids by air flow, etc., can solve the problems of complex operation and low grain screening efficiency, reduce work procedures, improve Grain screening efficiency and the effect of reducing space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

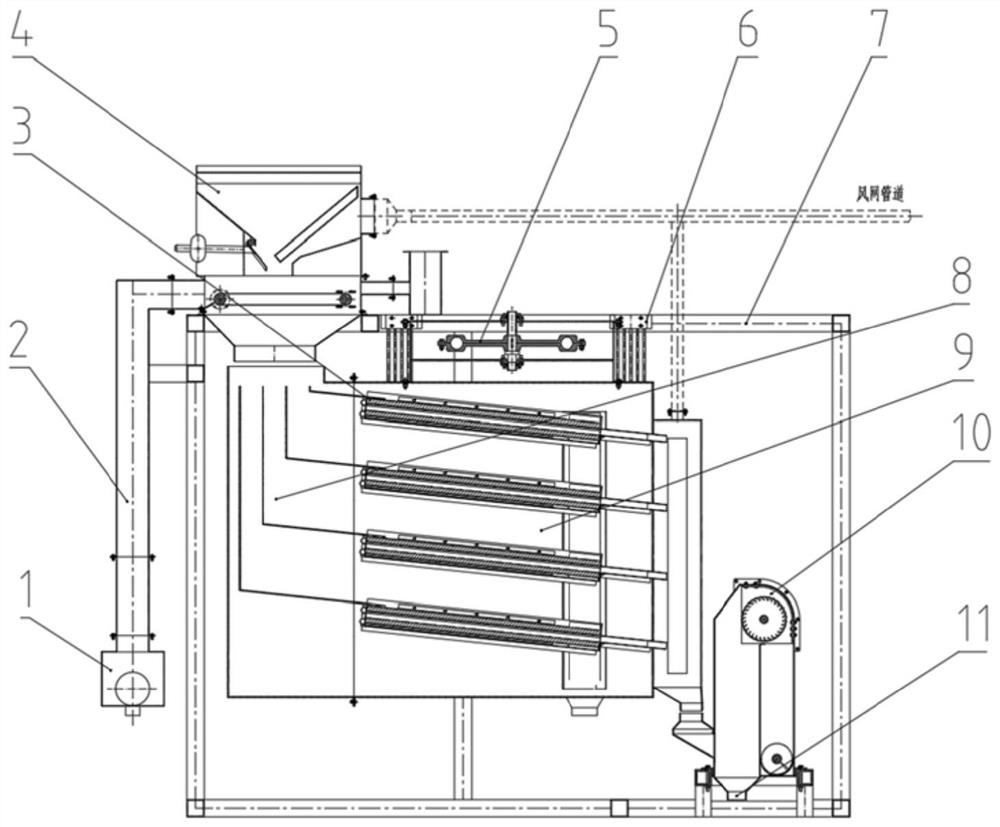

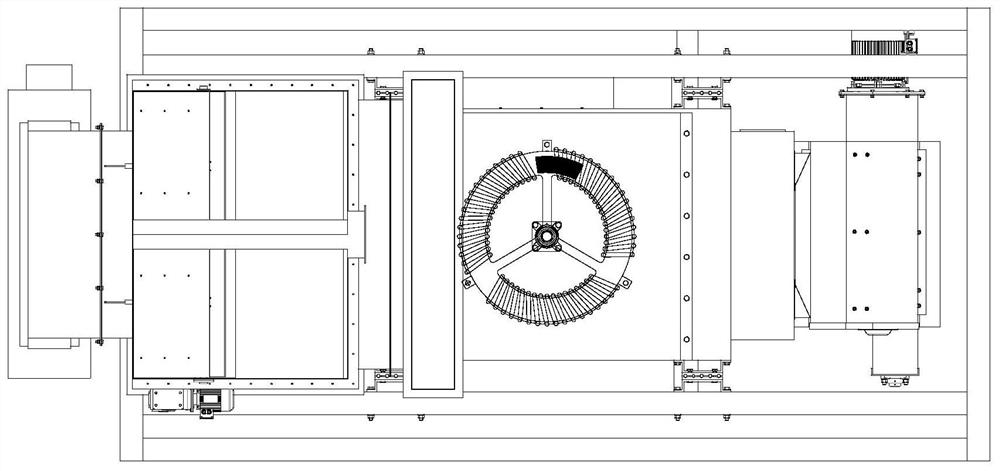

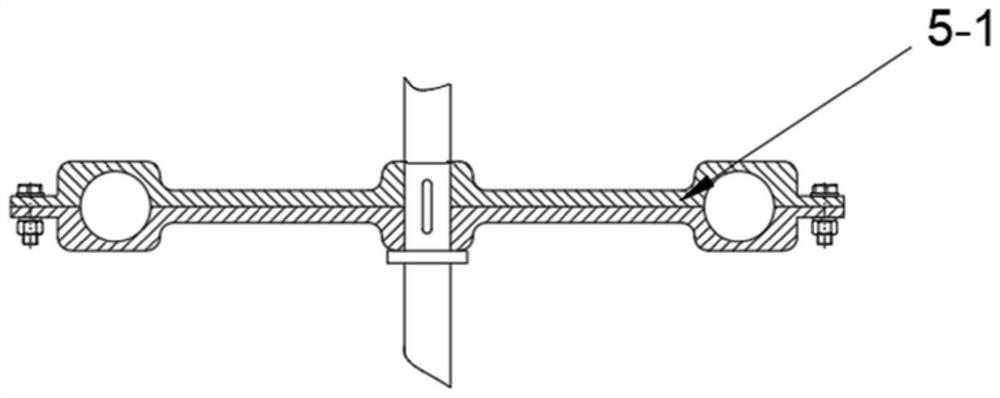

[0031] The invention provides a magnetic drive plane rotary screen, such as Figure 1-4 As shown in the figure, the magnetic drive plane rotary screen includes a screen body, and the inner longitudinal direction is provided with a multi-layer mesh belt screen 3, which is vibrated by force. The corresponding feed conduit 8 communicates with the feed port 4, and communicates with the discharge port 11 through the corresponding discharge conduit; the magnetic drive device 5 is connected to the screen body 9, and generates a driving force for driving the screen body to vibrate through the magnetic effect.

[0032] The sieve body 9 can vibrate under the action of external force, the mesh belt sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com