An integrated automatic plasma cutting and welding device

A welding device, cutting and welding technology, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, inconvenient precise positioning, and rising defective rate, so as to improve production efficiency and facilitate precise positioning , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

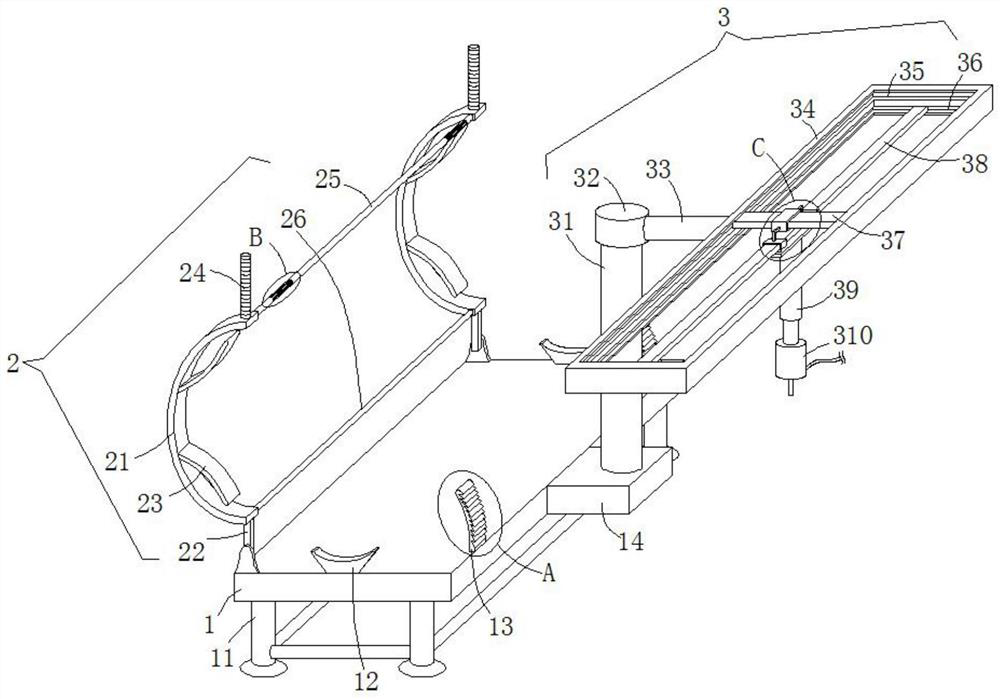

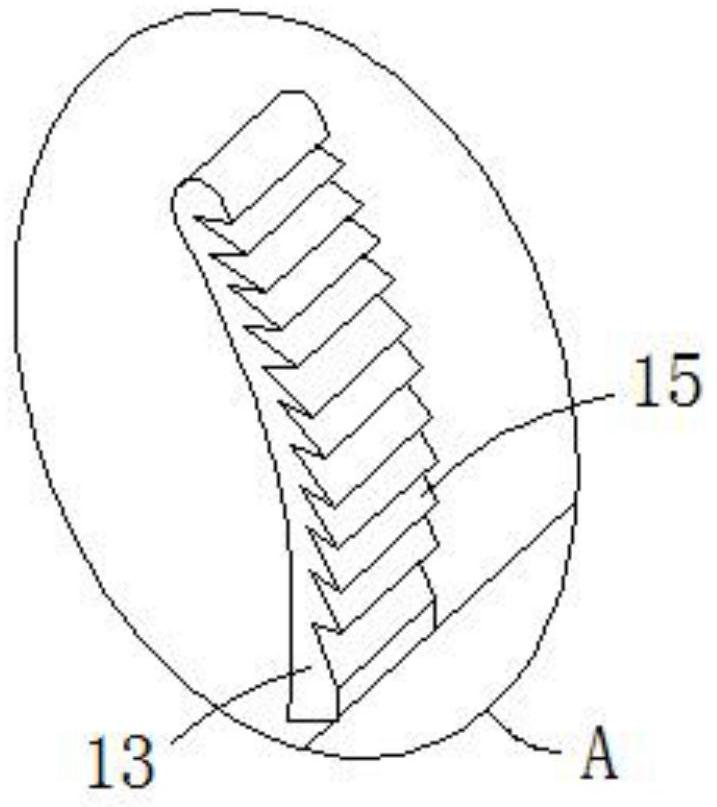

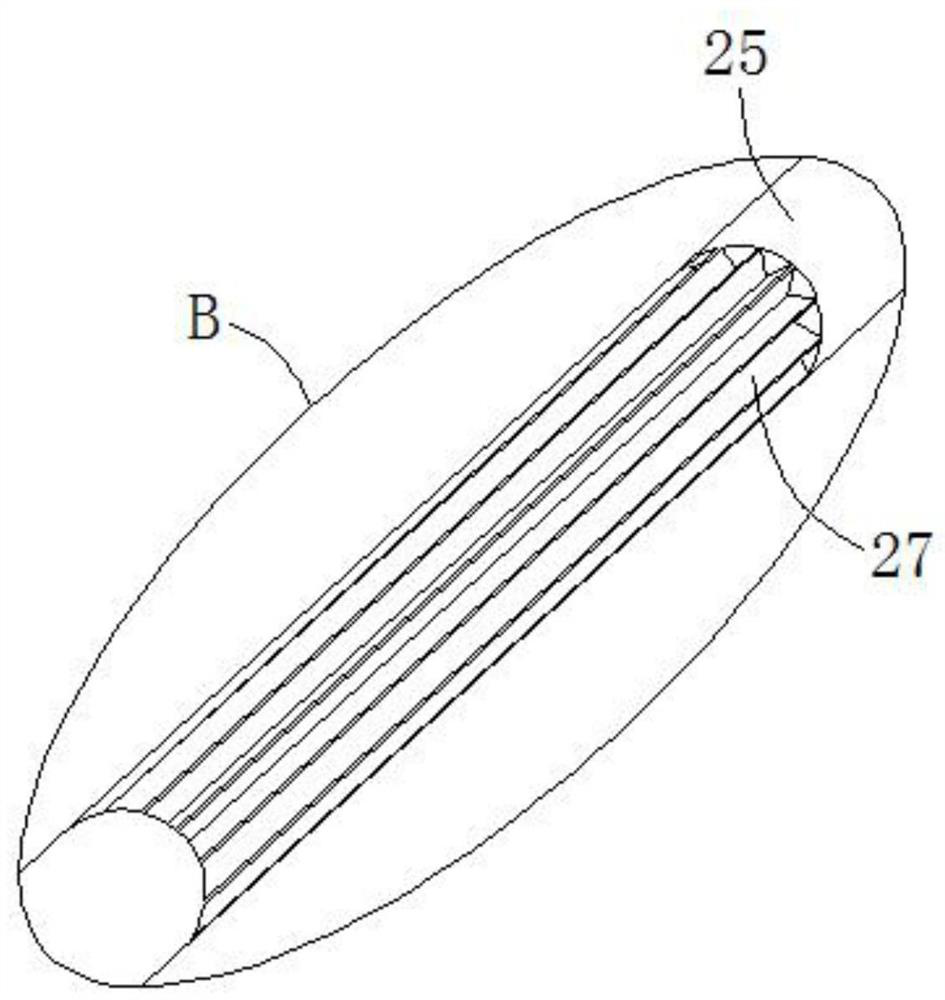

[0023] see Figure 1-4 , this embodiment provides an integrated automatic plasma cutting and welding device, including a base 1, a positioning mechanism 2 and a cutting and welding mechanism 3, the positioning mechanism 2 includes two arc-shaped positioning plates 21, two hinged rods 22, a second A connecting rod 25 and a second connecting rod 26, the front and rear sides of the right end of the top surface of the base 1 are provided with arc-shaped stainless steel limiting plates 13, and the right end faces of the two arc-shaped stainless steel limiting plates 13 are all provided with downward facing rightwards. The limit tooth block 15 inclined at 45 degrees, uses the limit tooth block 15 of two arc-shaped stainless steel limit plates 13 to effectively fix the downward positioning mechanism 2, so that the downward positioning mechanism 2 can be used to compress The axle housing to be cut and welded, and can prevent the downward pressure instability of the positioning mechani...

Embodiment 2

[0031] see Figure 1-4 , further improvements have been made on the basis of Example 1:

[0032] Two arc-shaped positioning plates 21 are fixedly welded with handles 24 at one end away from the hinge rod 22. By setting the handles 24, it is convenient to operate the two arc-shaped positioning plates 21 of the whole positioning mechanism 2 to rotate and press down or lift around the hinge point, saving Save time and effort.

[0033] The top end of the base 1 is welded with a matching support seat 12 in the middle of the front, rear and both sides, and the top surfaces of the two matching support seats 12 are arc-shaped. The arc-shaped stainless steel elastic pressure plates 23 distributed in a figure-eight structure are arranged on the inner side wall of each arc-shaped positioning plate 21 to press down the outer wall of the axle housing with two arc-shaped stainless steel elastic pressure plates 23 distributed in a figure-eight structure. The two ends of the axle housing ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com