Eye-brow shaping blade set welding machine and machining process thereof

A technology of blade set and welding machine, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as welding of blades and mesh sleeves that have not been described, and achieve the goal of promoting production efficiency, improving automation, and promoting bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

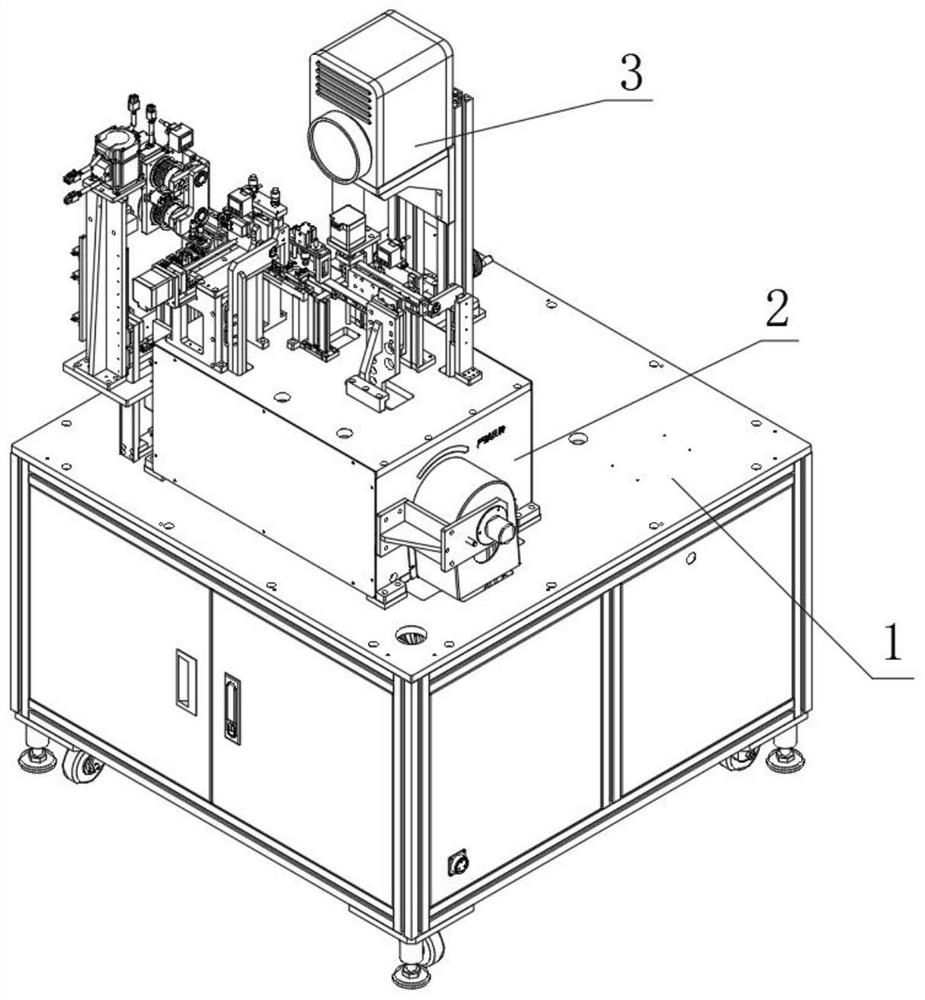

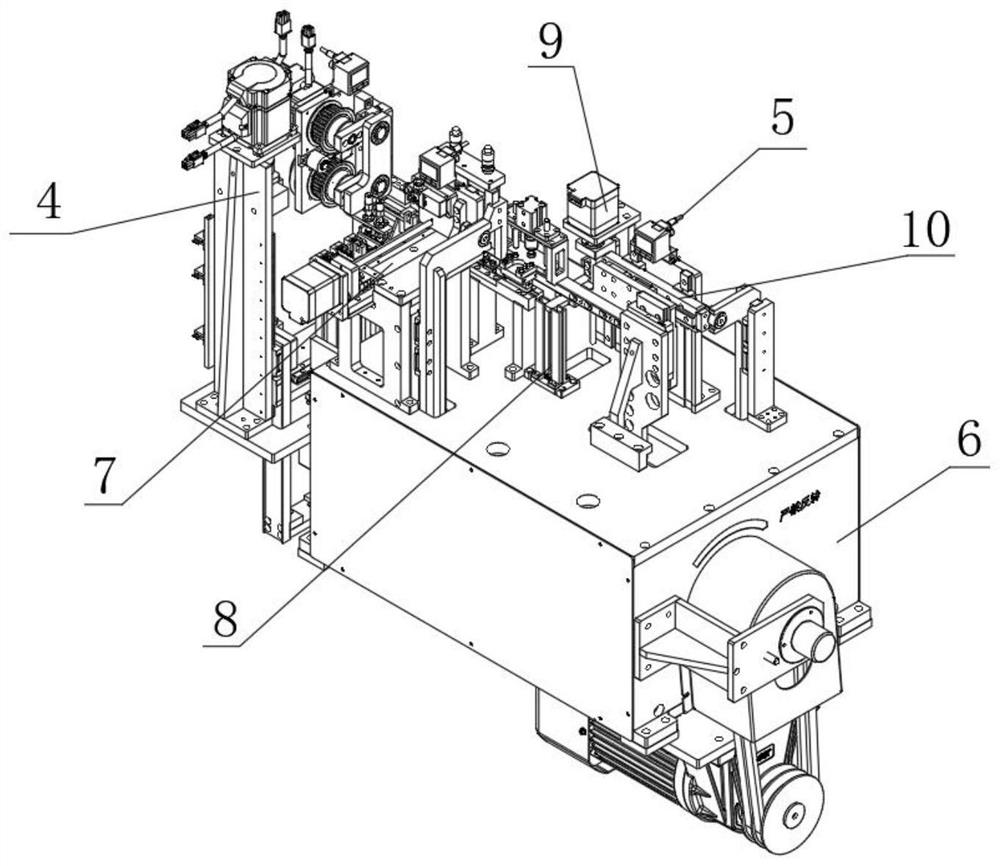

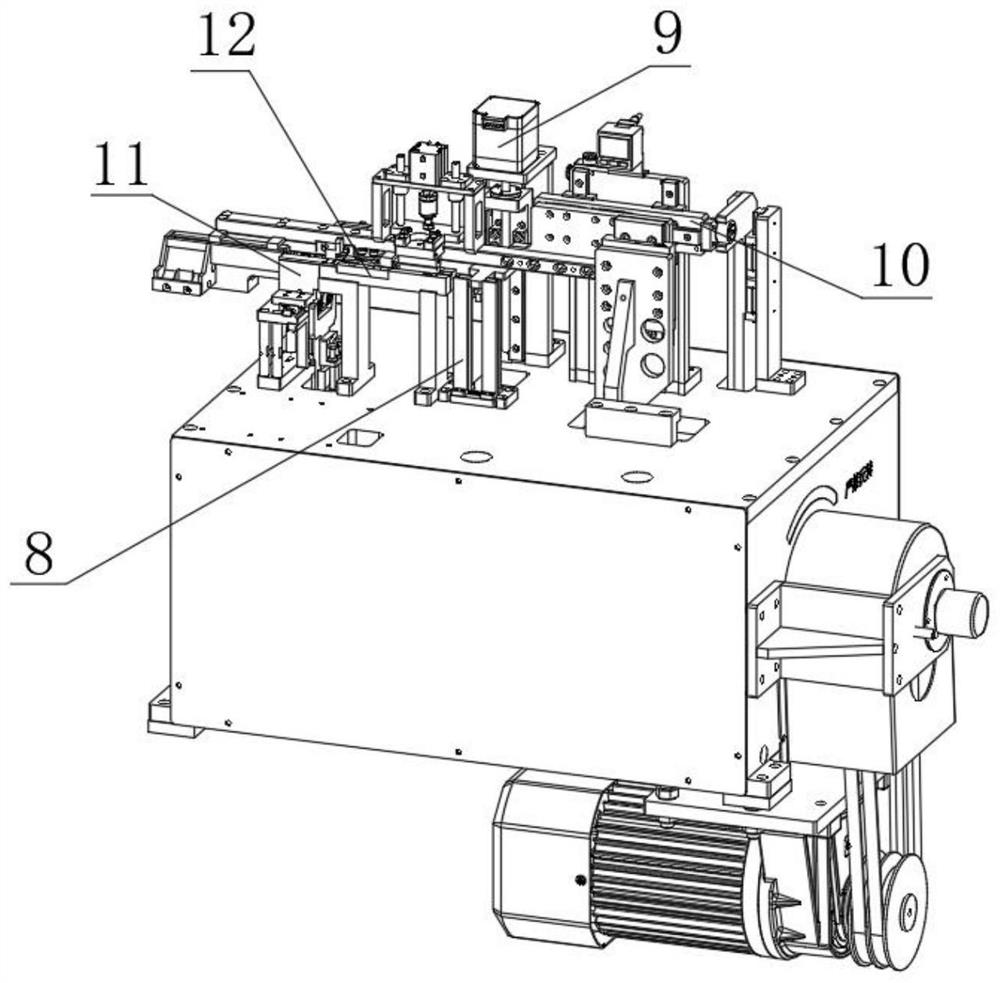

[0042] A kind of eyebrow trimming blade group welding machine, such as figure 1 Shown: includes a frame 1, a host 2 and a laser welding lens 3, the top outer wall of the frame 1 is fixed with a host 2 by bolts, and one side of the outer wall of the host 2 is fixed with a laser welding lens 3 by bolts, the host 2, such as figure 2 image 3 Shown: including material receiving mechanism 4, main working assembly 5, power distribution box 6, blade silo 7 and mesh sheet silo 8, said main working assembly 5, such as figure 2 image 3 As shown: it includes a mesh sheet feeding mechanism 9, a stepping mechanism 10, a working channel 12, a combination of a blade distribution die and a mesh sheet bending upper die 23, and a clamping and welding mechanism 11. The receiving mechanism 4 is fixed on the On one side of the top of the frame 1, the outer wall of the top of the frame 1 has mounting holes, and the power distribution box 6 is fixed in the mounting holes by bolts, and each com...

Embodiment 2

[0054] In this embodiment, on the basis of Embodiment 1, the processing technology of the eyebrow trimming blade in the welding machine is set forth, including the following steps:

[0055] S1: Push the net cover sheet 34 to the first working position 15 of the working channel 12 through the feeding mechanism 9;

[0056] S2: Push the mesh sheet 34 on the first working position 15 to the second working station 14 through the push rod 19, and the upper mold 24 for bending the mesh sheet and the lower mold 16 for bending the mesh sheet are attached to each other Bending the mesh sheet 34 in a manner;

[0057] S3: Push the bent mesh sheet 34 on the second working station 14 to the third working station 13 through the push rod 19; The mold delivery 26 pushes the blade 33 of the blade magazine 7 into the bent net cover sheet 34 on the third working position 13, and then clamps the rear clamp 29 of the front clamp 28 of the clamp welding mechanism 11 on the locking block 30 Move to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com