Chip overlapping assembly device

An assembly device and chip mounting technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high error rate, high investment cost, slow production cycle, etc., and achieves low error probability, low investment cost, The effect of fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the drawings.

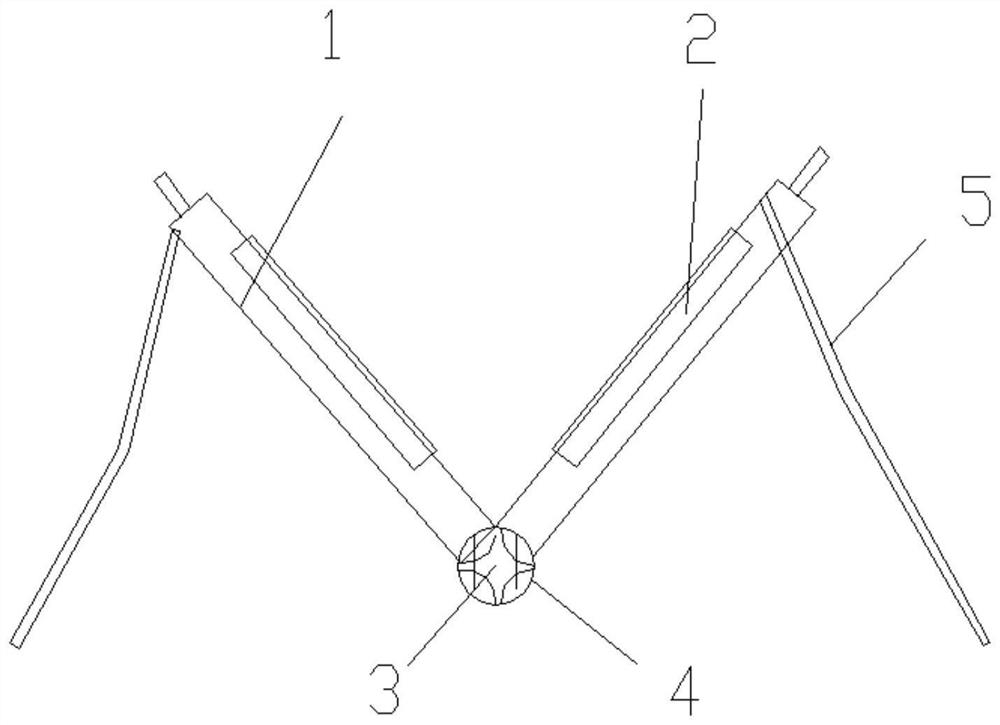

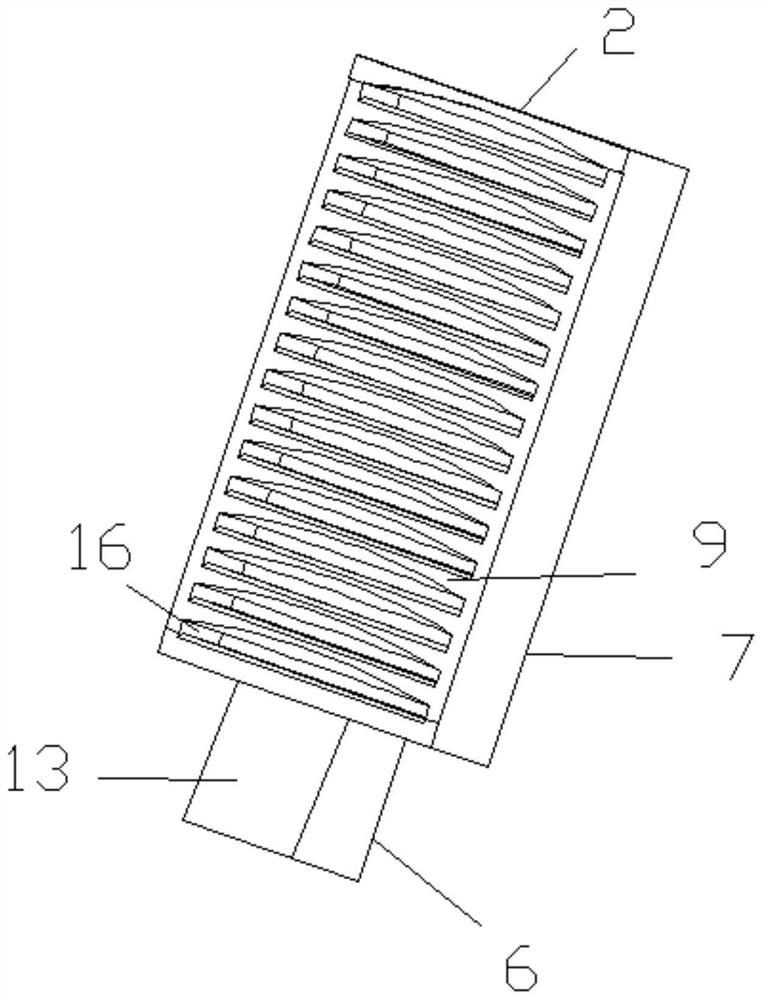

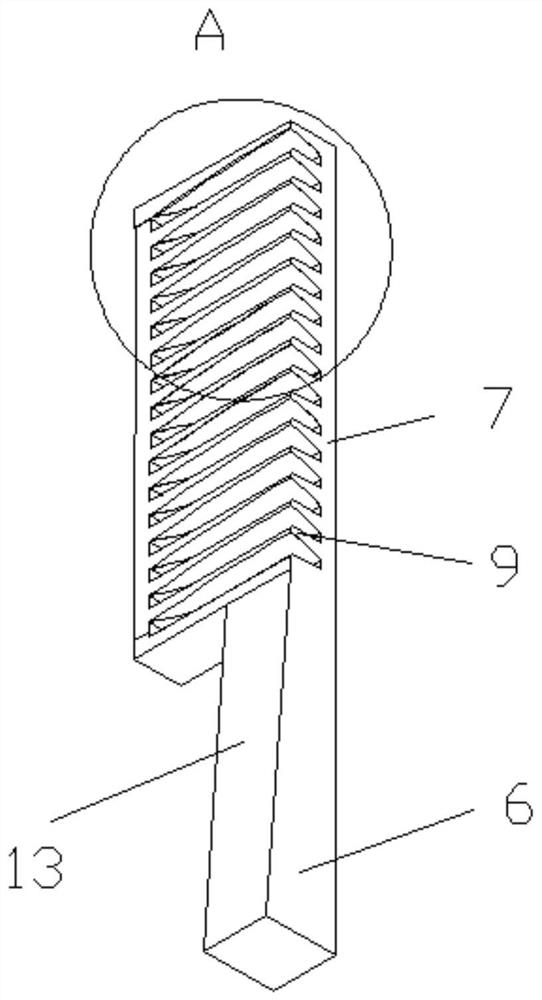

[0025] Such as Figure 1-6 As shown, the chip overlapping assembly device includes a main body panel 1 and a chip mounting block 2. There are two main body panels 1, and the bottom of one end of the two main body panels 1 is provided with a weightless folding support frame 5, and the two main body panels The other ends of 1 are connected by a pin shaft 3, the pin shaft 3 is provided with a limit spring 4, and each of the main body panels 1 is provided with a mounting groove, and the chip mounting block 2 is disposed in the mounting groove; The chip mounting block 2 includes a handle 6, a base 7 and a tank body 8, the handle 6 is connected to the base 7 or is integrated, the base 7 is provided with a plurality of tank bodies 8, and the tank body 8 There are a plurality of vertically upward spacer bars 9 between them. An arc-shaped cut edge 10 is respectively arranged on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com