Rubber product punching equipment

A product, rubber technology, applied in the field of punching equipment for rubber products, can solve the problems of insecurity and high processing costs, and achieve the effect of avoiding confusion, reducing work burden and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

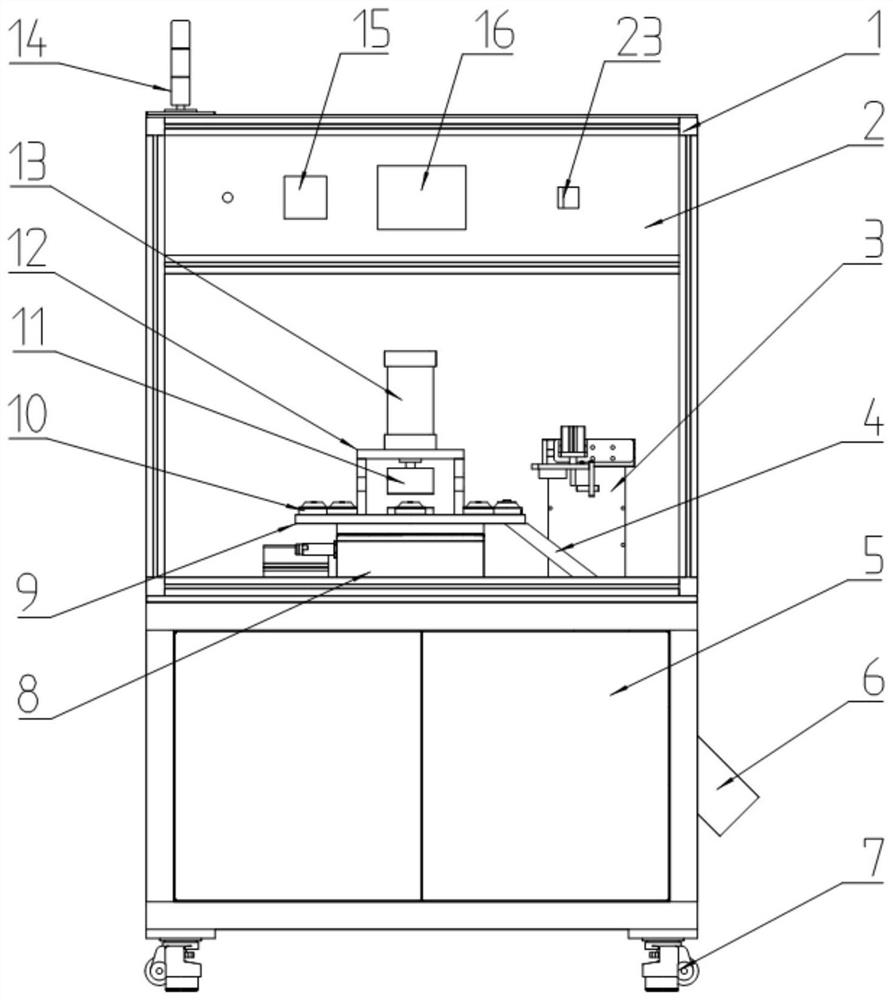

[0037] A punching equipment for rubber products, basically as attached figure 1 As shown, including the rack 1, the rack 1 is arranged in three layers, which are the upper layer, the middle layer and the lower layer in turn. The upper layer and the middle layer are built into a rectangular frame structure through connecting columns. The rectangular frame structure is specifically divided into an upper rectangular frame and a lower rectangular frame. The upper rectangular frame corresponds to the upper layer, and the lower rectangular frame corresponds to the middle layer. The way to install the baffle. The lower floor of the frame 1 is a work cabinet 5, the upper surface of the work cabinet 5 is set as a workbench, and the upper surface of the workbench corresponds to the bottom surface of the lower rectangular frame.

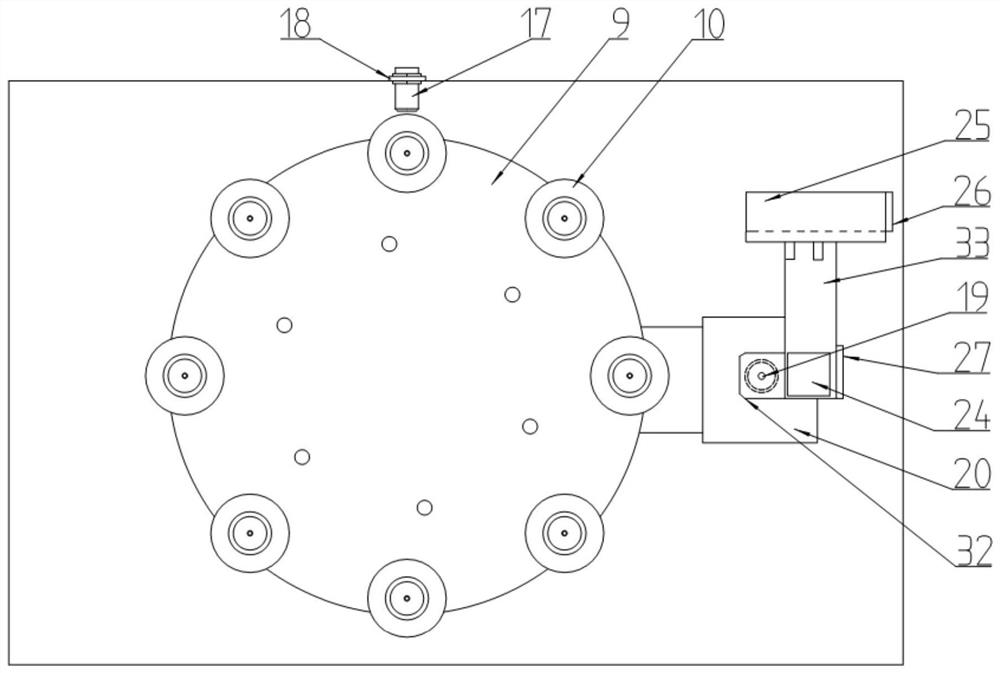

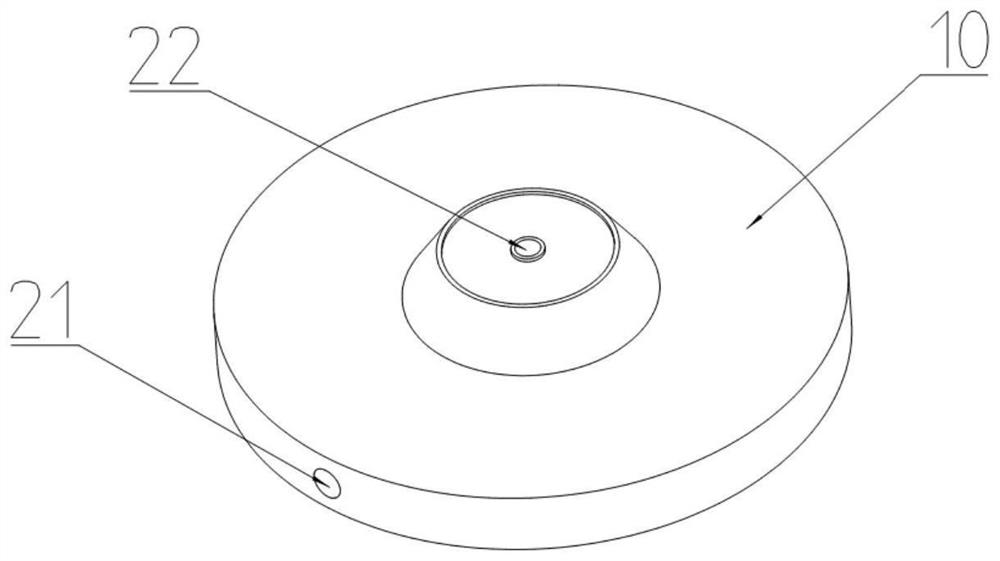

[0038] The working table is equipped with an automatic turntable, an adsorption mechanism, a cutting mechanism, an air blowing mechanism and a material discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com