A Powertrain Control Method for Reducing Torsional Vibration of Driveline

A technology of powertrain and control method, applied in the direction of control device, etc., can solve the problems of reducing the stiffness of the clutch damper, exceeding the torsional amplitude value, not taking into account the economical drivability and the thermal load of the clutch, etc. Ride comfort, the effect of improving the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

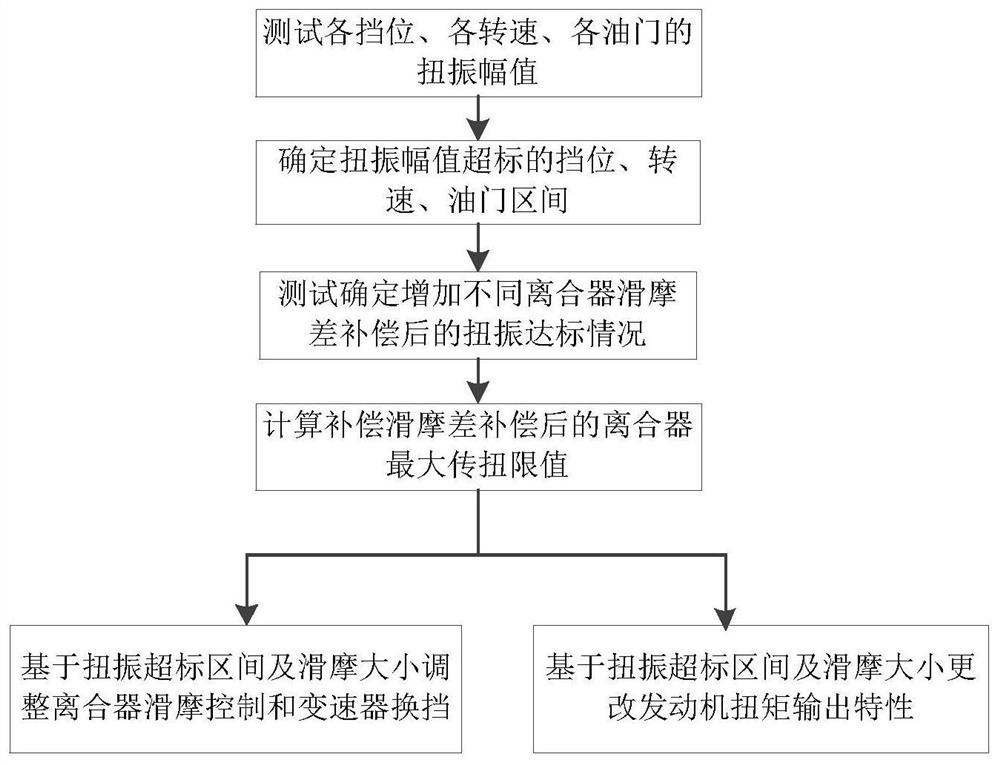

[0041] A powertrain control method for reducing torsional vibration of a drive train, specifically comprising the following steps:

[0042] Step 1: Test the torsional amplitude of each gear, each speed, and each throttle opening through the instrument, as shown in Table 1;

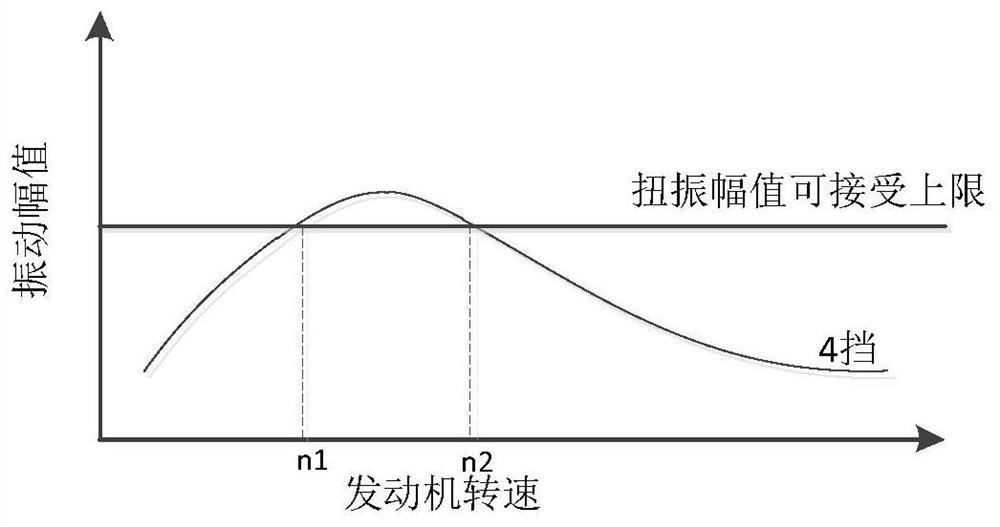

[0043] Step 2: According to the test results of Step 1, determine the range of the gear, speed and throttle opening where the torsional vibration amplitude exceeds the standard. The interval is the exceeding interval, the schematic diagram is as follows image 3 shown.

[0044] Step 3: Determine the up-to-standard condition of the torsional amplitude of the drive train after increasing the slip friction compensation of different clutches.

[0045] Step 4: According to the sliding friction difference determined in step 3 and the heating characteristics of the clutch, determine the maximum transmission torque under this sliding friction difference;

[0046] Step 5: According to the maximum transmission to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com