Small-sized bagged formula machine

A formula and bagging technology, applied in the field of medical devices, can solve the problems of low accuracy, deviation, correspondence between the drug drop port and the drug bag, etc., so as to improve the efficiency, improve the accuracy, improve the positioning accuracy and the accuracy of dispensing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

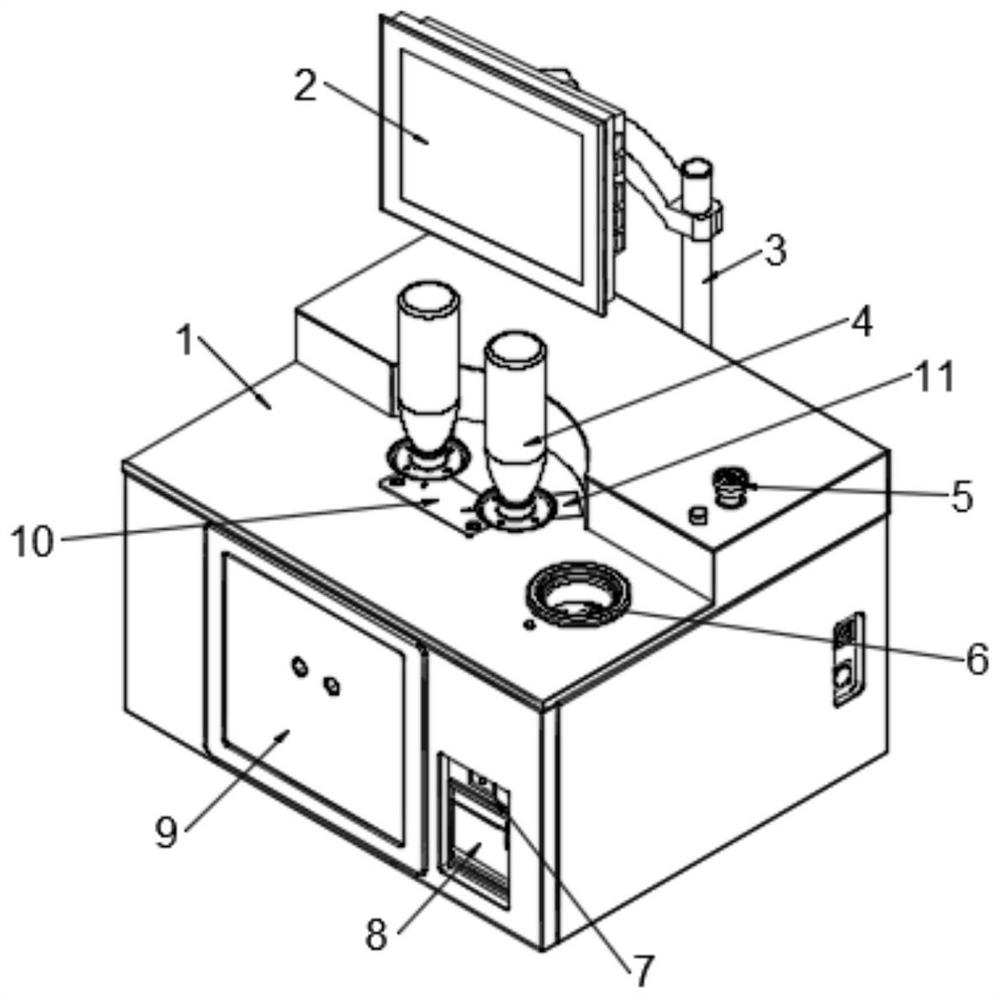

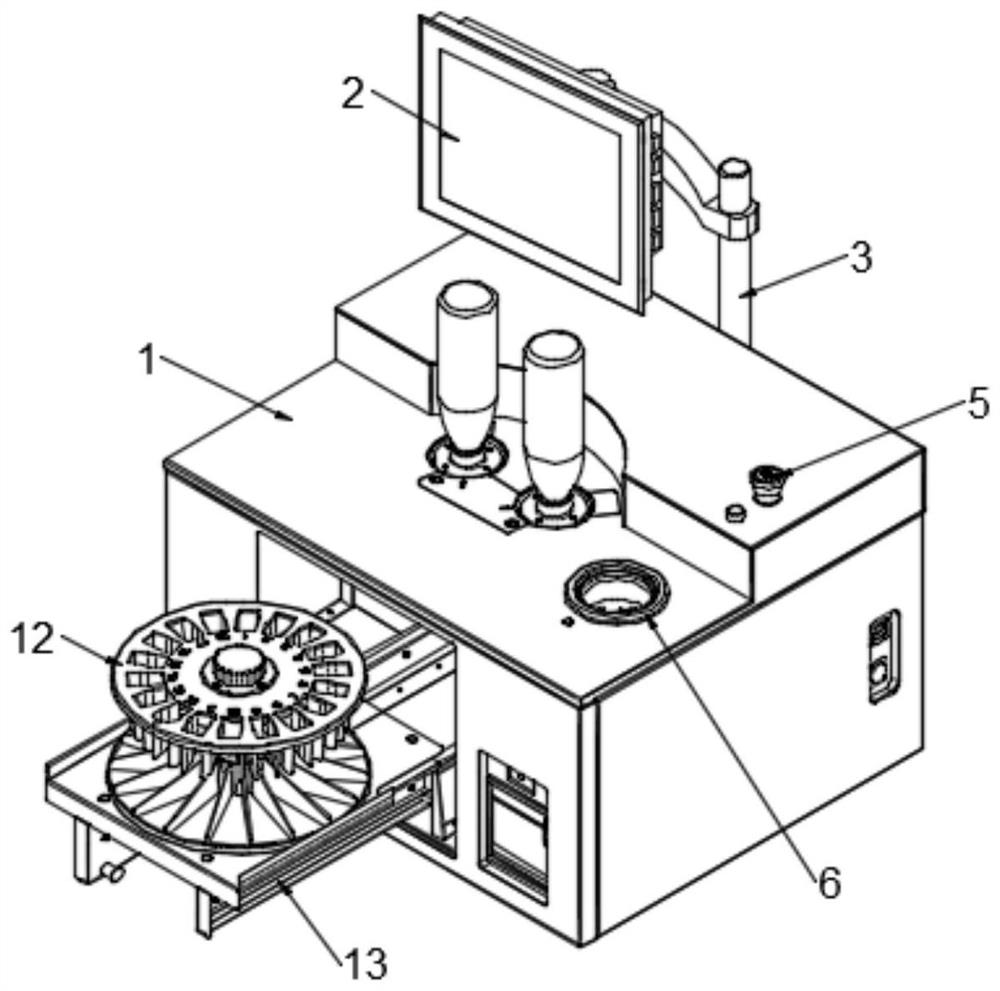

[0022] see Figure 1~2 , in an embodiment of the present invention, a small bag assembly square machine, comprising a formula machine main body 1, a hatch 9 is installed on the front side wall of the formula machine main body 1; an industrial computer is fixed on the side wall of the formula machine main body 1 Bracket 3, industrial computer 2 is installed on the bracket 3 of the industrial computer, a turntable 12 is arranged in the main body 1 of the formula machine, and two sets of dispensing modules 4 arranged symmetrically are arranged above the turntable 12, and the main body 1 of the formula machine is also provided with a dial for driving the turntable. 12 running turntable drive assembly 13; through the industrial computer 2, various instructions are issued to guide the operation of each module of the small bag assembly square machine. And the in-place adjustment and pick-and-place of the medicine bag, two groups of adjustment modules 4 are fixed on the top of the med...

Embodiment 2

[0030] see Figure 1~2 , in the embodiment of the present invention, a small bag assembly square machine is different from embodiment 1 in that an emergency stop switch 5 is provided on the main body 1 of the formula machine; it is convenient to control the small bag assembly square machine to stop in an emergency .

[0031] In the small bag assembly square machine, two groups of dispensing modules 4 are placed symmetrically, and when reset, they correspond to the No. 1 drug dispensing port and No. 5 drug dispensing port on the turntable 12 respectively. The layout is reasonable and the dispensing efficiency is improved.

[0032] The turntable drive assembly 13 drives the turntable 12 to precisely position when each grid rotates, and accurately corresponds the medicine dropping port of the dispensing module 4 to the medicine bag of the turntable 12, thereby improving the accuracy of dispensing.

[0033] The dispensing module 4 completes the dispensing process according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com