Anti-winding mechanism for end face fibers of textile machinery rotating parts

A technology of rotating parts and textile machinery, applied in the field of textile fiber processing, can solve the problems of easy loosening and slipping of fibers, laborious operation, easy wear of drum hinges, etc., and achieve the effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

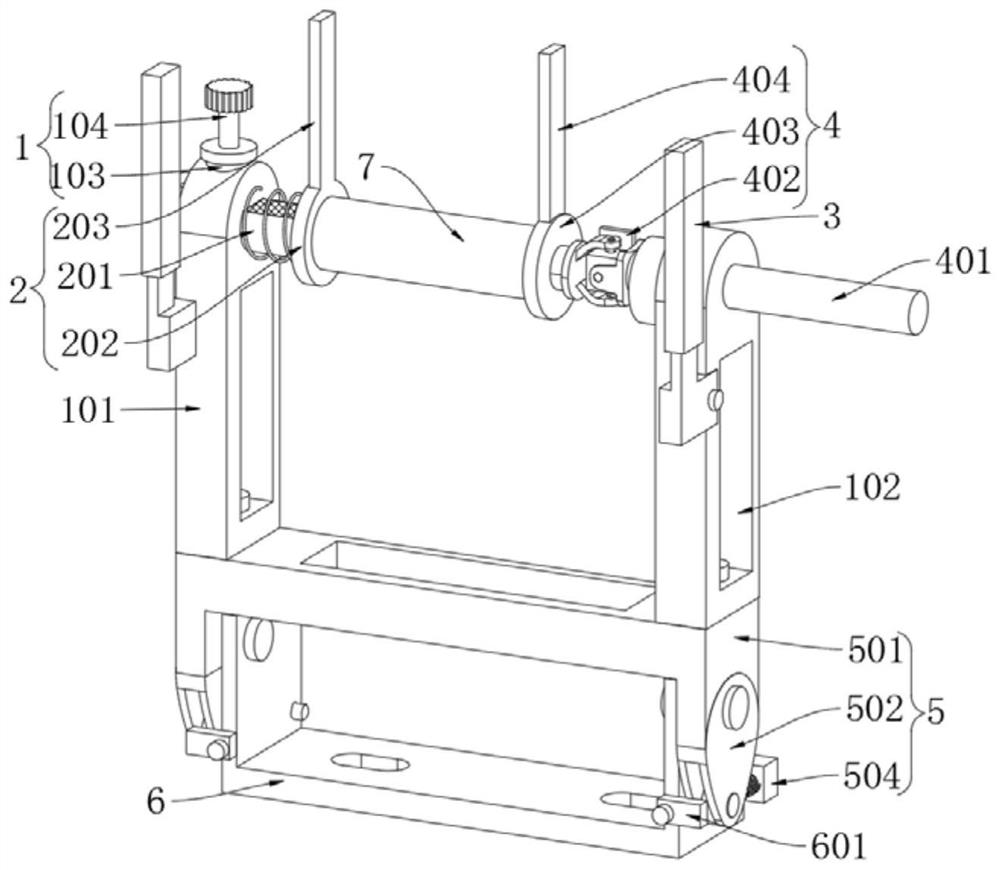

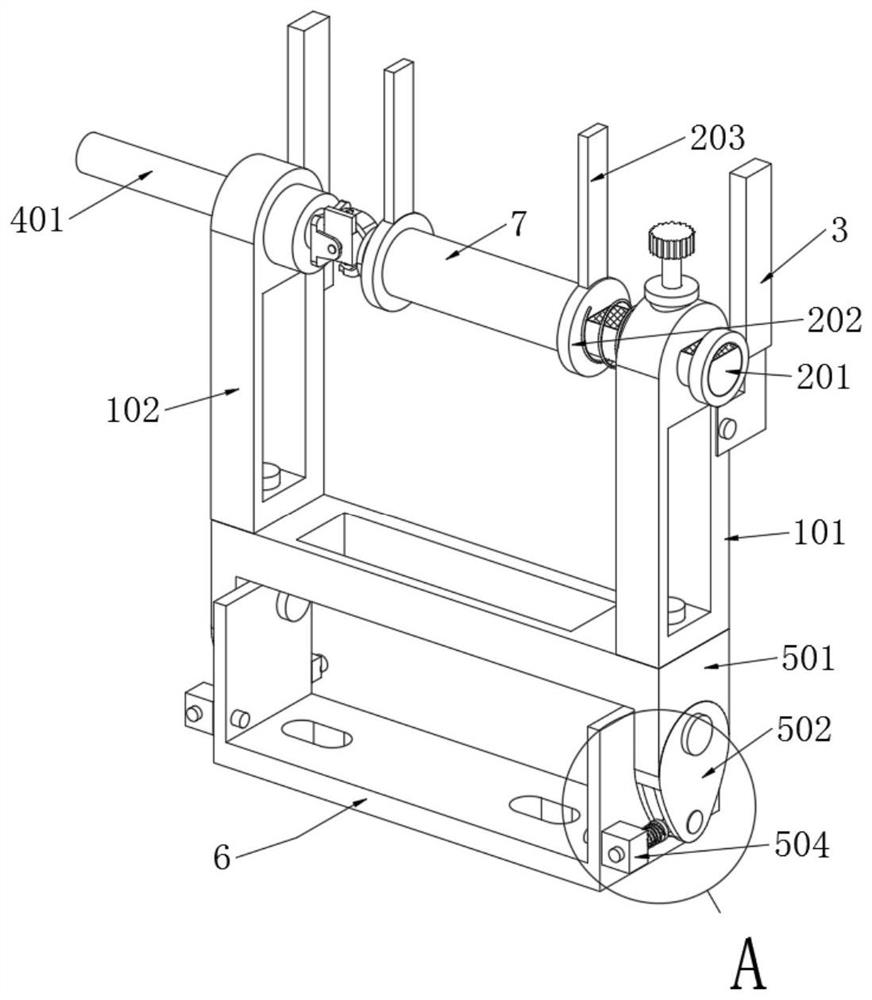

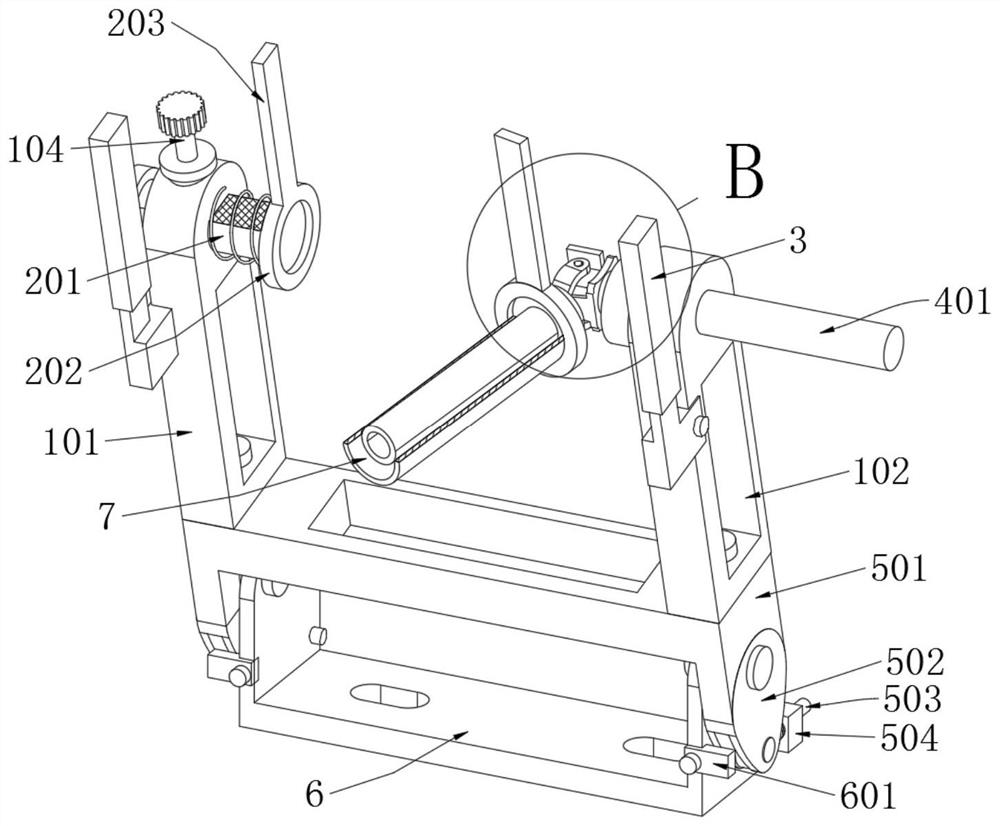

[0038] as attached figure 1 to attach Figure 11 Shown:

[0039] The present invention provides an end face fiber anti-winding mechanism for rotating parts of textile machinery, which includes a support mechanism 1; a rectangular hole for reducing weight is opened on the support mechanism 1, and an elastically connected clamping mechanism 2 is installed on the support mechanism 1 to clamp A pull ring is installed on the mechanism 2; the support mechanism 1 includes a support plate A101, a support plate B102, a nut placement seat 103 and a clamping bolt 104, and the bottoms of the support plate A101 and the support plate B102 are processed with rectangular blocks, and the U-shaped support The seat 501 is symmetrically provided with two limiting grooves matching with the rectangular block, and one side of the supporting plate A101 and the supporting plate B102 are provided with limiting grooves matching the handle 3, and the supporting plate A101 is provided with a nut placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com