Mobile wave-proof wharf

A mobile and anti-wave technology, applied in the field of marine engineering, can solve the problems of mobile docks that do not consider wave dissipation measures, small wave force and wave height, and single incoming wave direction, so as to ensure the safety of navigation, rapid construction, and weakened impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

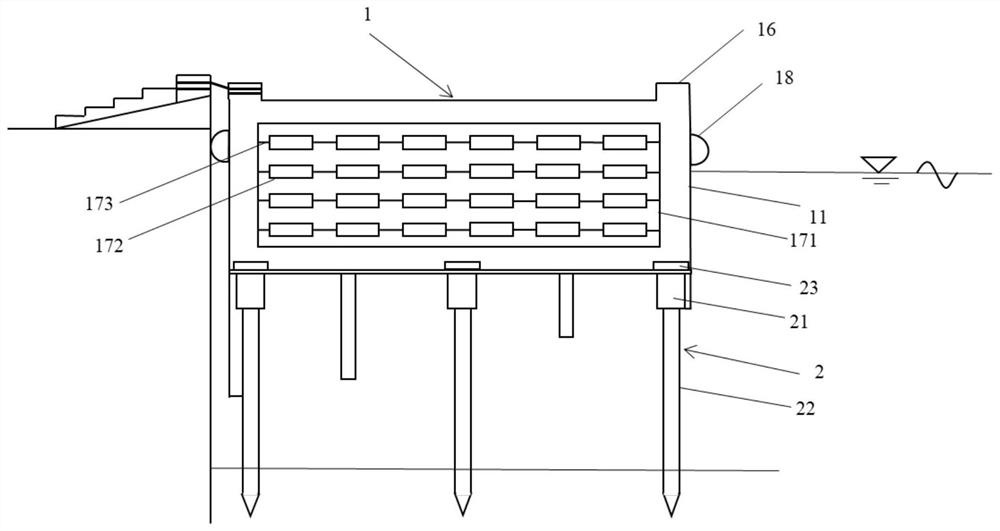

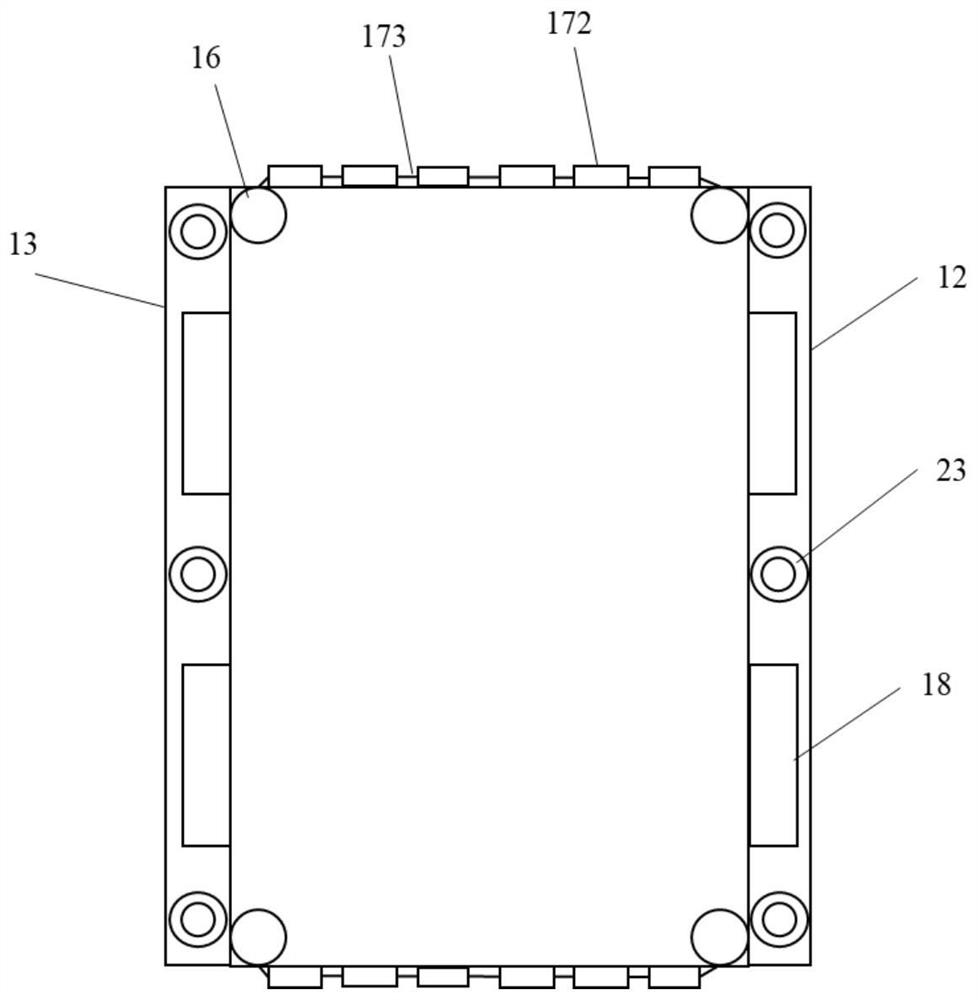

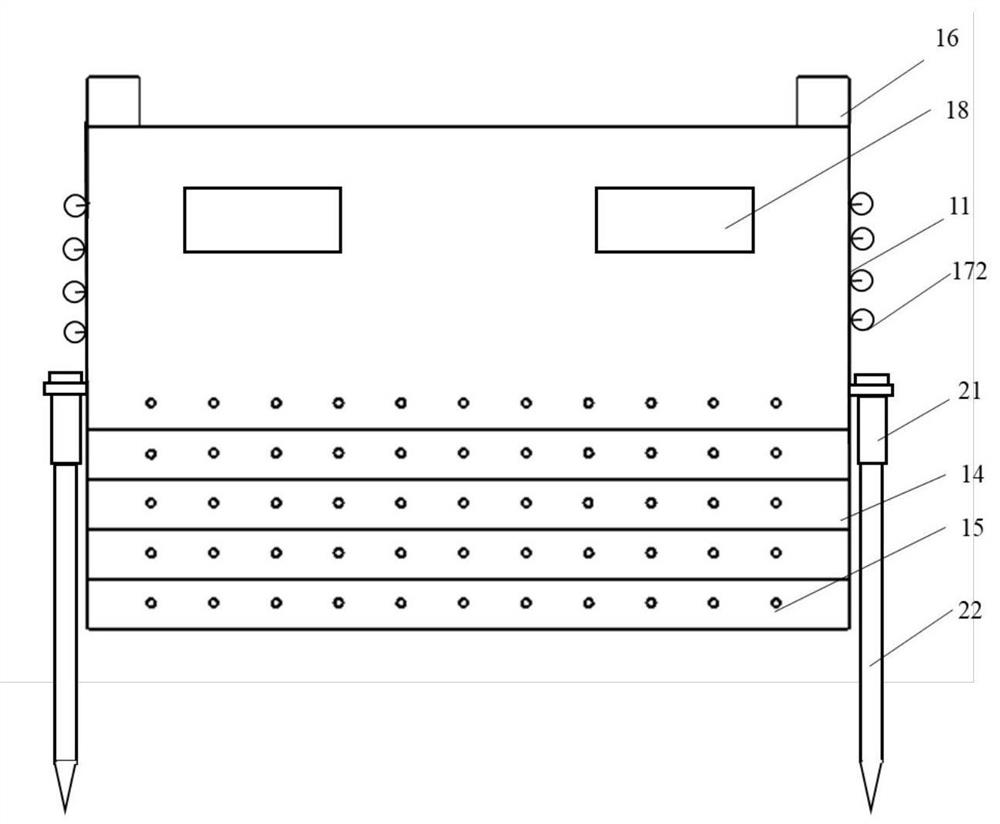

[0033] The overall structure

[0034] A mobile anti-wave wharf includes a box structure 1 and a fixed structure 2, and the box structure 1 is fixed on the surface of a water body through the fixed structure 2. Such as figure 1 As shown, the box structure 1 includes a buoyancy tank 11, and the fixed structure 2 includes a guide positioning ring 21 and a reinforced concrete solid pile 22; 21 is set vertically downward; the guide positioning ring 21 is connected with a reinforced concrete solid pile 22 of matching size, and the reinforced concrete solid pile 22 is connected with the guide positioning ring 21 and the load-bearing steel plate by a flange. On the base plate of buoyancy tank 11, be fixedly connected with a plurality of steel plates 14 that are arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com