Foundation pit inclined strut device and construction method

A technology of diagonal braces and foundation pits, which is applied in infrastructure engineering, excavation, sheet pile walls, etc., can solve the problems of resource material waste, difficult disassembly, long construction period, etc., and achieve the effect of increasing friction and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

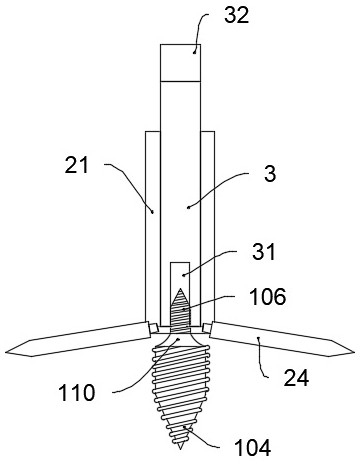

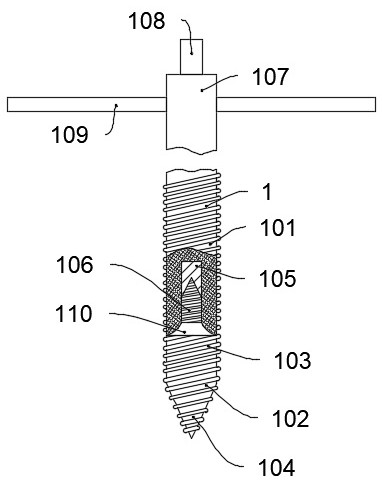

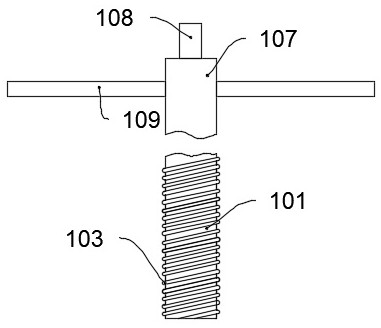

[0037] Such as Figure 1-7 As shown, a foundation pit brace device includes an embedded assembly 1, the embedded assembly 1 includes an upper embedded rod 101 and a lower fixing head 102, the lower end of the upper embedded rod 101 is provided with a first screw hole 105, the lower fixing head 102 and the upper The surface of the embedding rod 101 is provided with a helical pattern 103, through the helical thread 103, when the embedding component 1 rotates into the ground, the surrounding soil is conveyed out by a screw, which is convenient for the embedding component 1 to go deep. The friction between the lower fixed head 102 and the soil effectively prevents the lower fixed head 102 from breaking away from the soil. The upper end of the lower fixed head 102 is fixedly connected with a base 110, and the base 110 can move with the movement of the lower fixed head 102. The upper end of base 110 is fixedly connected with screw rod 106, and screw rod 106 can move with the movemen...

Embodiment 2

[0043] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the cross-section of the side of the positioning leg 24 away from the central shaft of the positioning cylinder 2 is tapered, and when the positioning leg 24 rotates around the ring block 23, The surrounding soil can be squeezed, and the soil resistance that the positioning leg 24 is subjected to when rotating can be reduced by setting the taper.

[0044] Thread the embedded rod 101 and the lower fixed head 102 and fasten them, select a suitable position on the soft surface soil surface, rotate the upper embedded rod 101 and the lower fixed head 102 by turning the handle 109 and press them into the soil, and the soil is The spiral pattern 103 is rotated and discharged, and the upper embedded rod 101 and the lower fixing head 102 gradually go deep underground to form the preliminary positioning and fixing of the lower fixing head 102;

[0045] The preliminarily fixed upper embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com