A heat dissipation structure and excavator

A technology of heat dissipation structure and heat dissipation plate, which is applied in the arrangement of soil movers/excavators, power plant cooling combination, construction, etc., can solve the problems of slowing down the progress of the project, failure of the excavator body, and untimely heat dissipation, etc., to achieve The effect of reducing downtime, speeding up the progress bar, and improving cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Attached to the following Figure 1-5 This application will be described in further detail.

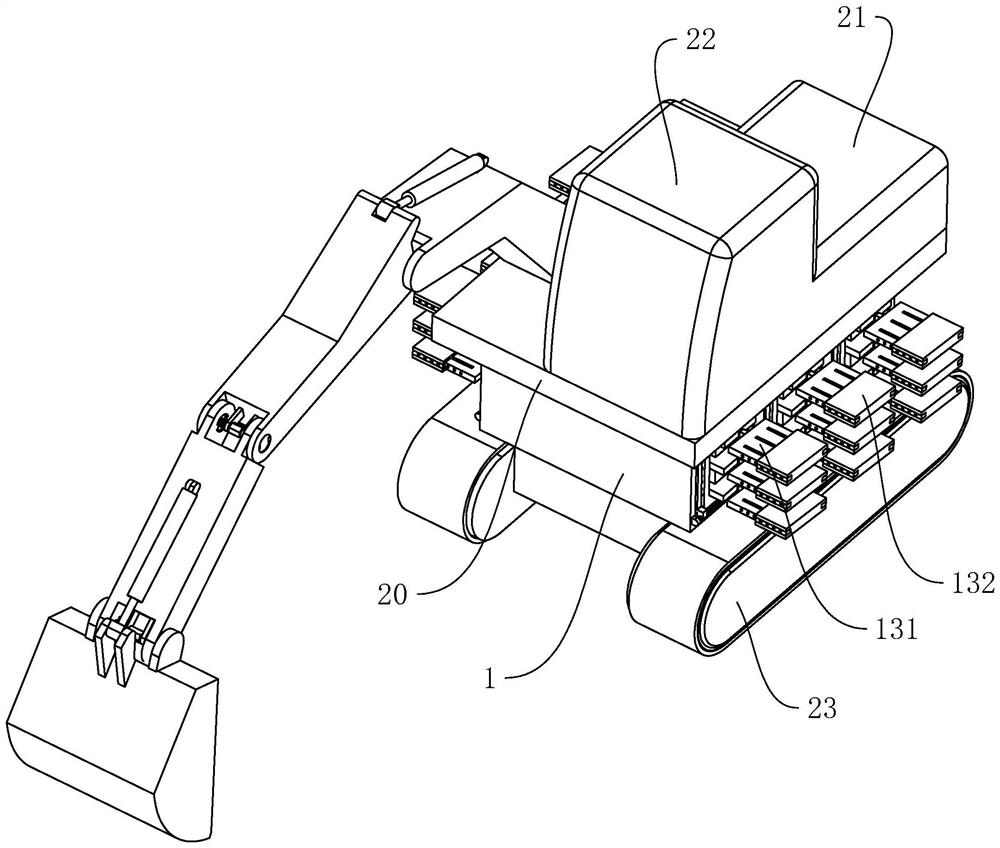

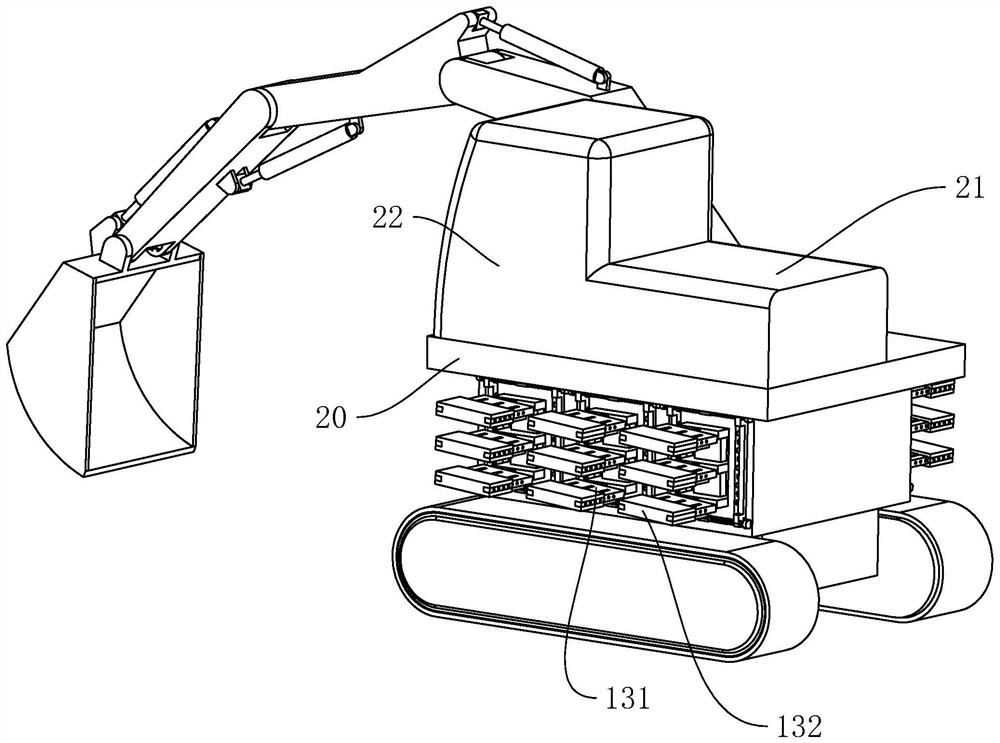

[0037] The embodiment of the present application discloses a heat dissipation structure, refer to figure 1 , figure 2 , a heat dissipation structure, including a mounting frame 1, the mounting frame 1 is sleeved according to the machine base 20 of the excavator and is tightly fitted and fixed by bolt penetration, so that the heat generated in the machine base 20 can stably escape from the machine base 20. The internal transmission is transmitted to the side wall of the machine base 20 , and the side wall of the machine base 20 is transmitted to the installation frame 1 .

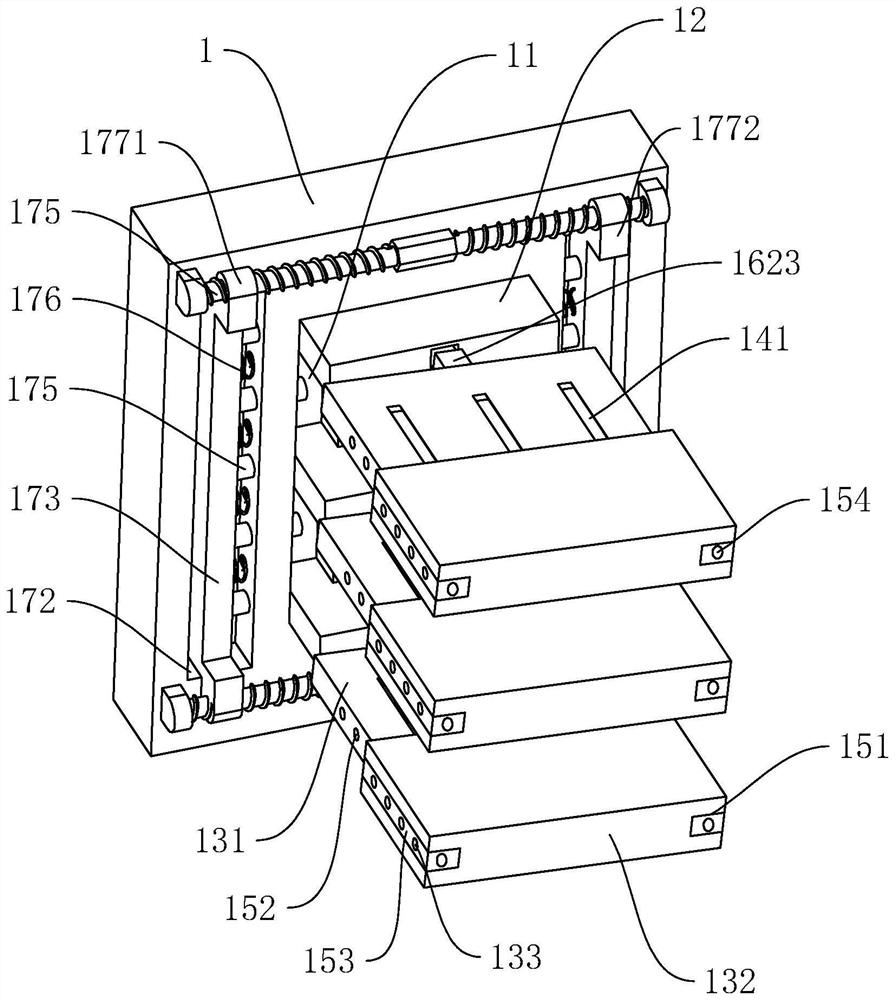

[0038] Among them, refer to image 3 , Figure 4 , a heat dissipation component is arranged at the position of the outer wall of the mounting frame 1, and a plurality of heat dissipation components are symmetrically and evenly arranged on both sides of the mounting frame 1. Specifically, the heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com