Turbine of small-medium gas turbine and working method

A gas turbine and turbine technology, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problem that the cooling structure of gas turbines is not suitable for small and medium gas turbine turbines, etc. The effect of high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

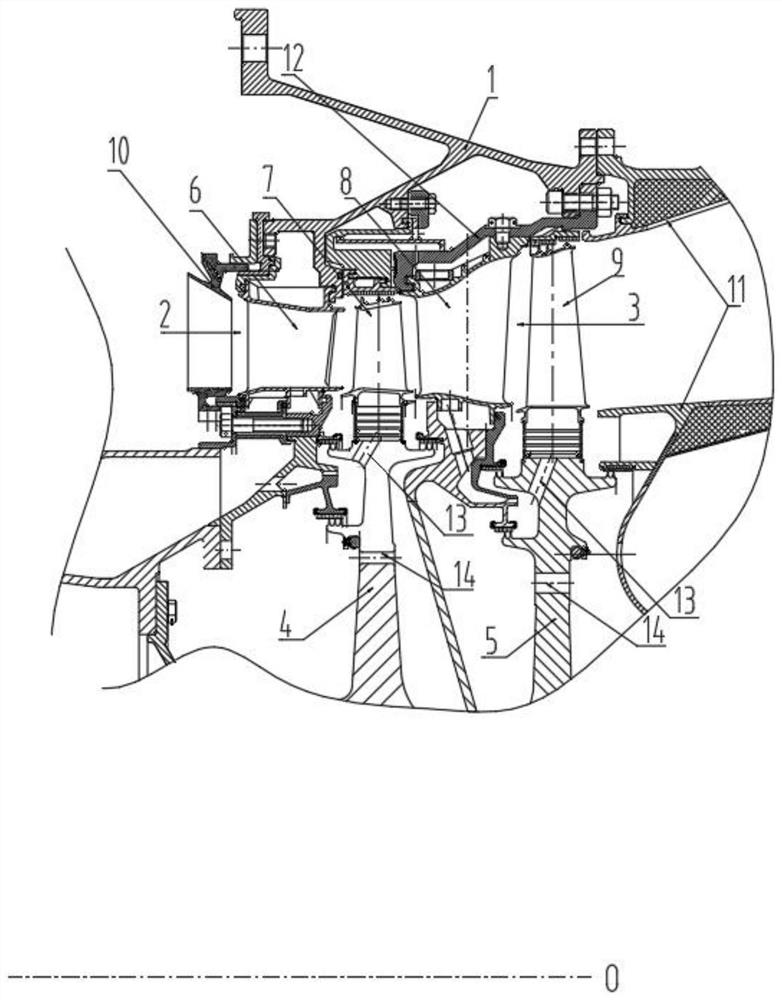

[0032] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, the turbine of a kind of small and medium-sized gas turbine of this embodiment includes turbine cylinder 1, turbine inlet 2, turbine outlet 3, high-pressure turbine rotor 4, low-pressure turbine rotor 5, a static stage blade 6, first-stage moving blade 7, second-stage stationary vane 8, second-stage moving blade 9 and retaining ring 12, the two ends of the turbine cylinder block 1 respectively have a turbine inlet 2 and a turbine outlet 3, and the turbine cylinder The high-pressure turbine rotor 4 and the low-pressure turbine rotor 5 are arranged in sequence from the inlet side to the outlet side of the body 1, the outlet side of the turbine cylinder block 1 is connected with the retaining ring 12, the first-stage stator blade 6 is connected with the turbine cylinder block 1, and the first-stage dynamic The blade 7 is connected to the high-pressure turbine rotor 4 and drives the high-...

specific Embodiment approach 2

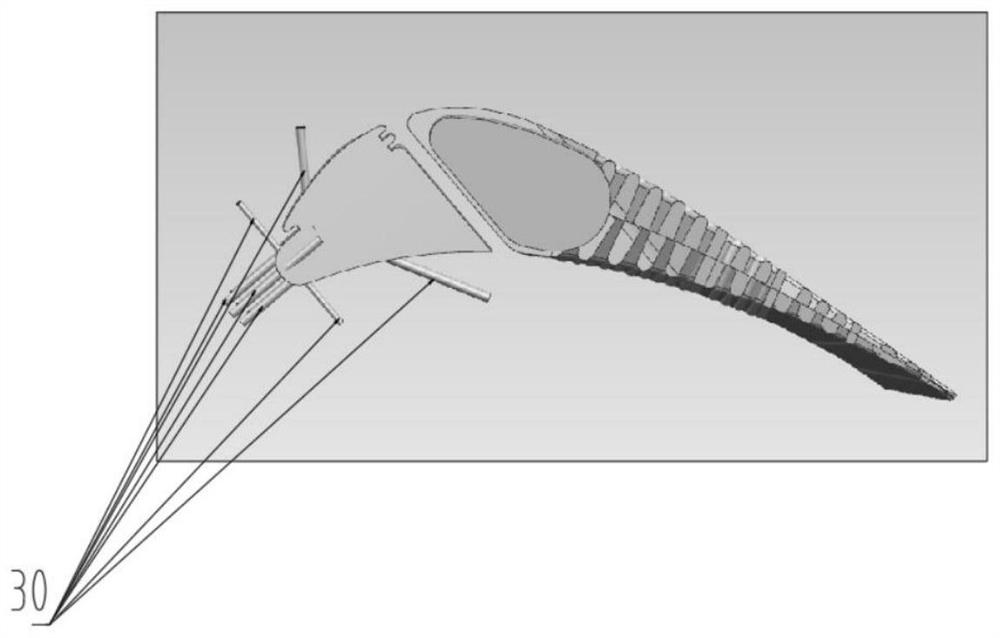

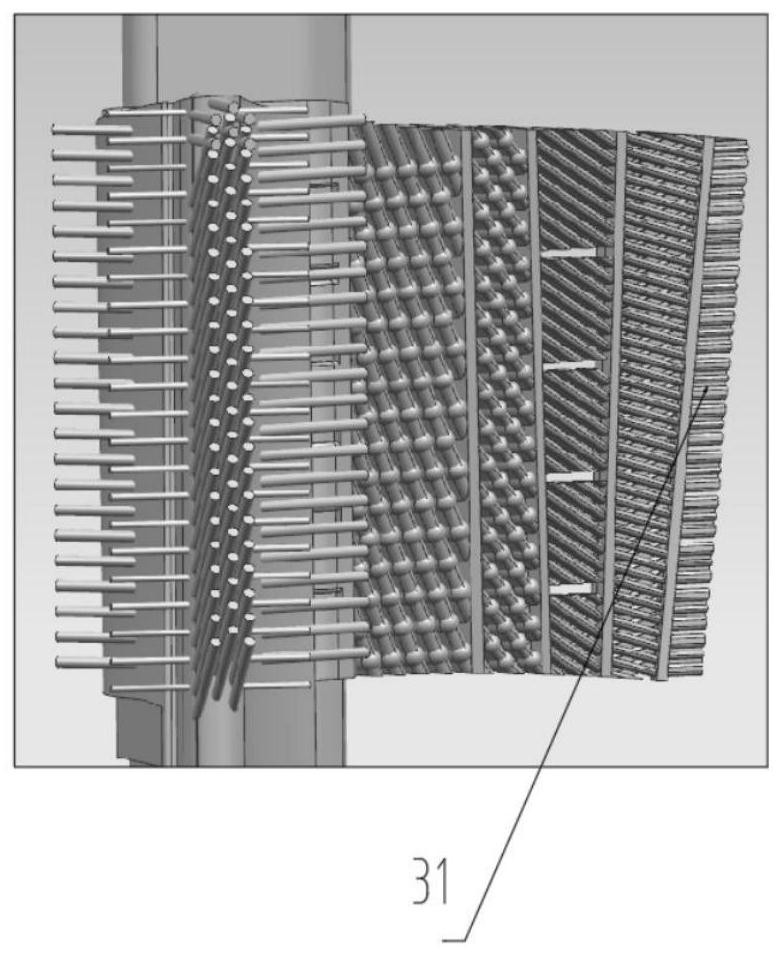

[0036] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, a turbine of a small and medium-sized gas turbine in this embodiment, the first-stage stator blade 6 and the second-stage stator blade 8 both adopt a matrix rib structure, and the front edge of the first-stage stator blade 6 is provided with a film hole 30 ; Both the primary moving blade 7 and the secondary moving blade 9 adopt a matrix rib structure, and the matrix rib is a regular structure.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1Describe this embodiment, a turbine of a small and medium gas turbine in this embodiment, the turbine cylinder 1 is provided with several cooling air passages along the axis O, and the cooling air passages are connected with the first-stage vane 6, the first-stage The internal passages of the rotor blade 7, the second-stage stator blade 8 and the second-stage rotor blade 9 and the gas channel are connected, and the low-temperature air flows into the interior of the first-stage stator blade 6 and the second-stage stator blade 8 through the cooling air channel on the cylinder block 1 channel, finally flows into the gas channel, and cools the components along the way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com