Motor mounting frame, fan assembly and air purifier

A motor mounting frame and fan technology, applied in electric components, electromechanical devices, electrical components, etc., can solve problems such as wind wheel friction, achieve stable installation, reduce the number of brackets, and ensure assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

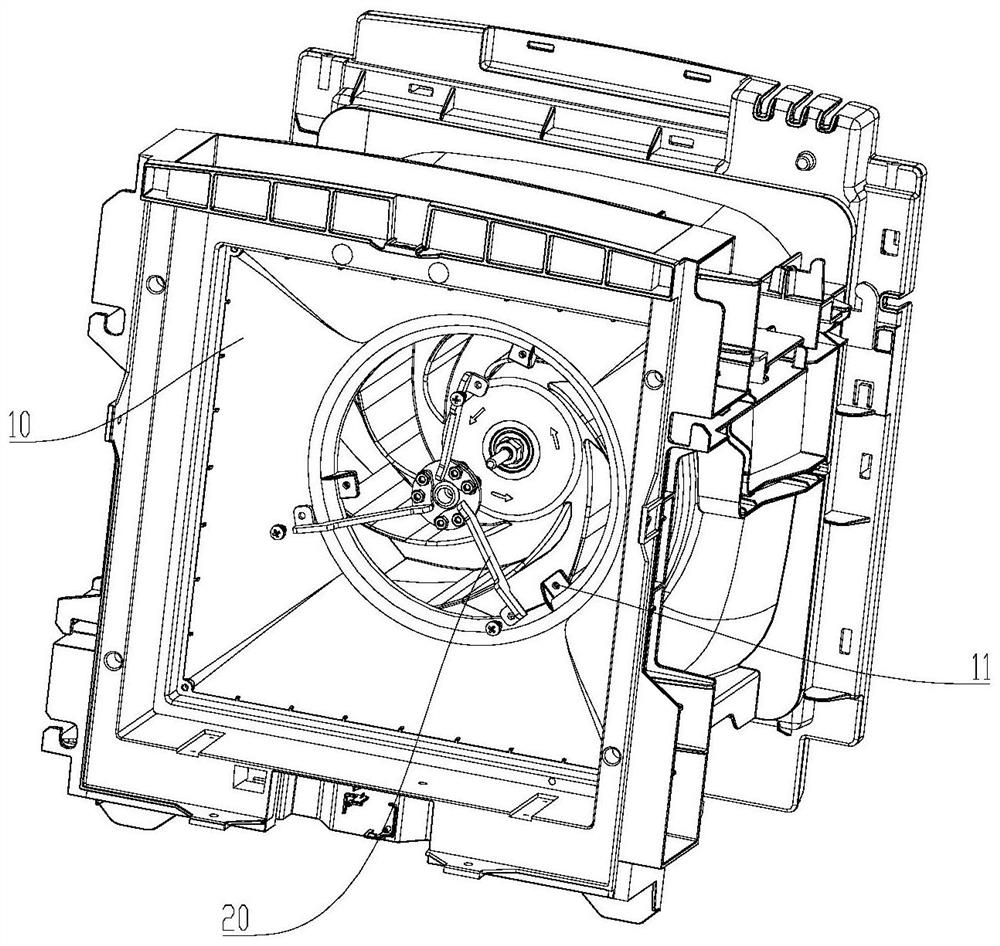

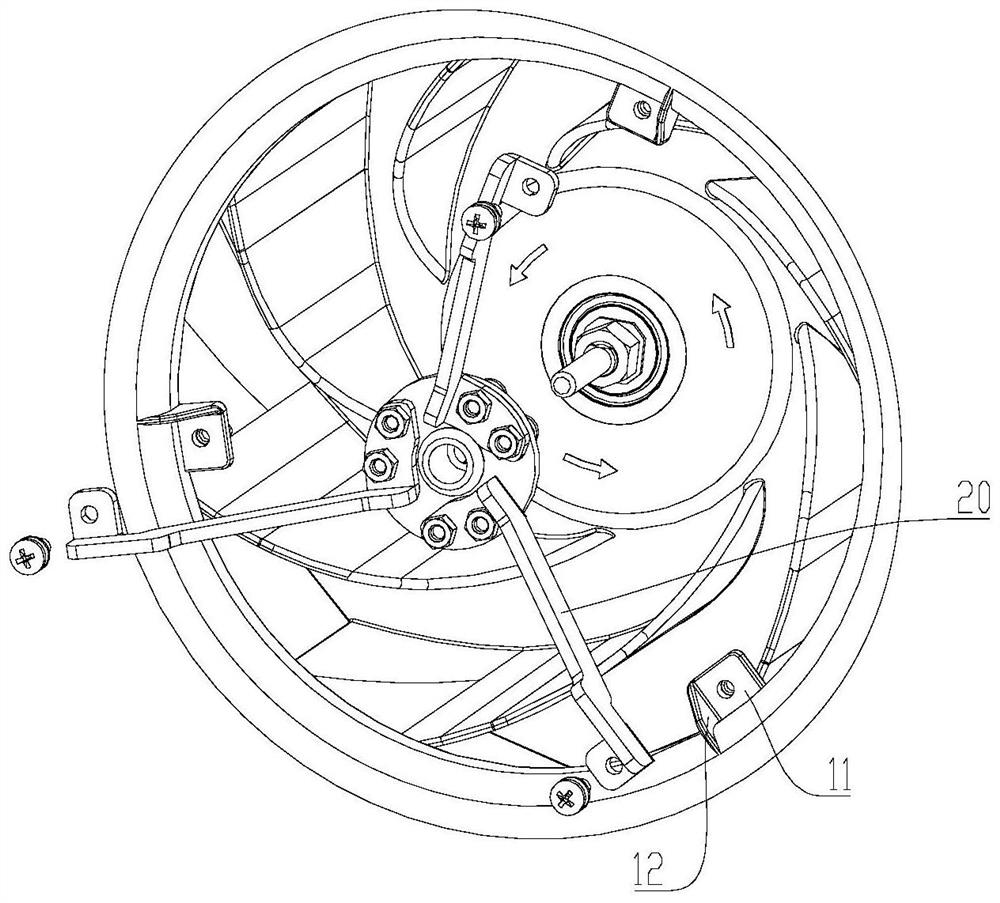

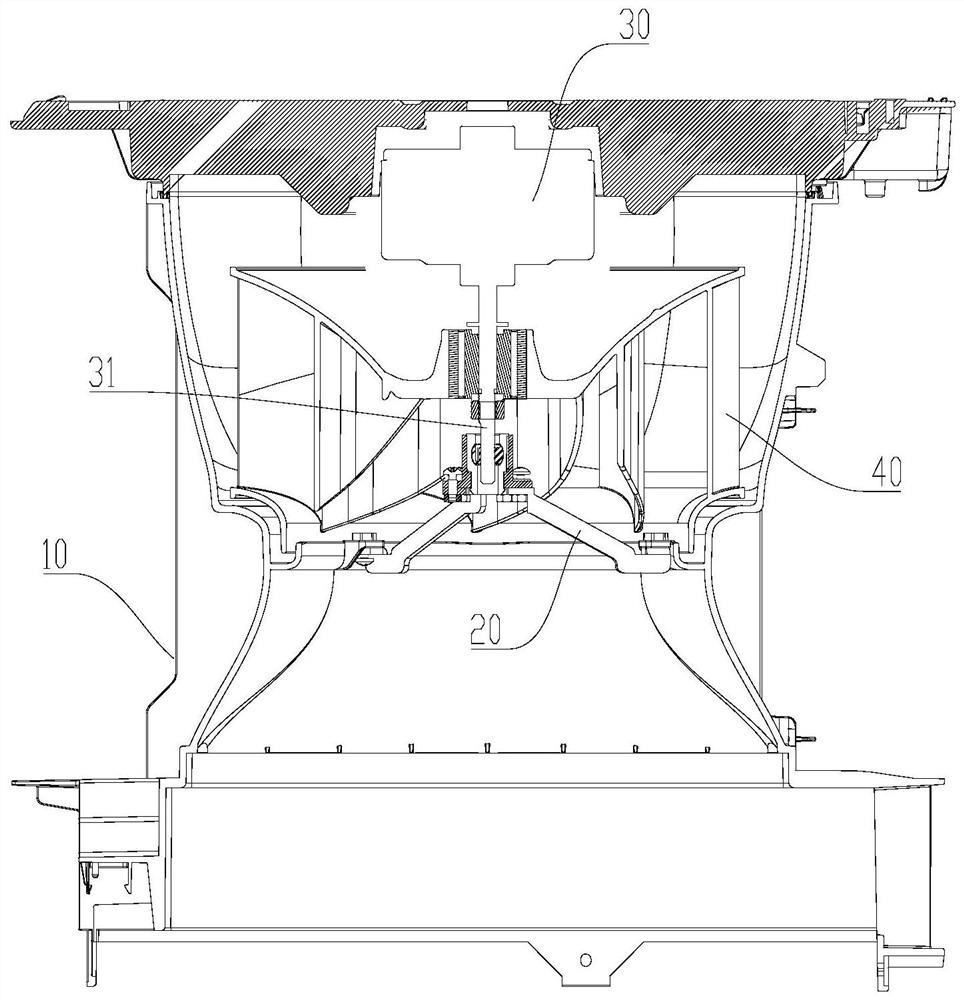

[0057] to combine Figure 5-Figure 8 As shown, the motor mounting bracket provided in this embodiment includes:

[0058] The shaft sleeve 21 has a through hole 211 formed therein;

[0059] The bearing 24 is directly or indirectly assembled and connected with the shaft sleeve 21, and a positioning shaft hole 241 is formed inside the bearing 24 in a direction parallel to the axis of the through hole;

[0060] At least part of the outer edge of the sleeve 21 is provided with a sleeve flange 212 , and a fixing position 214 is formed on the sleeve flange 212 .

[0061] Preferably, the sleeve 21 is configured as a cylindrical structure, and the through hole 211 is hollowly formed inside it along the axial direction. Preferably, the shaft sleeve 21 is configured as a thin-walled structure.

[0062] Preferably, the sleeve flange 212 extends radially along the outer surface of the sleeve 21, and the sleeve flange 212 is arranged around the sleeve 21; preferably, the sleeve flange 21...

Embodiment 2

[0093] to combine Figure 9 As shown, this embodiment serves as the deformation structure of the motor mounting frame provided in the first embodiment above. It differs from the above embodiment in that the two ends of the bracket 22 cancel the L-shaped bending structure, and the two ends of the extension part 222 The flange is added to strengthen the structural strength of the bracket 22 .

[0094] Preferably, the flange is located on the same side of the plane where the extension part 222 is located.

Embodiment 3

[0096] to combine Figure 10 As shown, this embodiment serves as the deformation structure of the motor mounting frame provided in the first embodiment above. The plane where the shape structure is located is perpendicular to the axial direction of the through hole 211 .

[0097] Preferably, flanges are formed on both side edges of the plate structure of the extension part 222 along the width direction, so as to increase the structural strength of the bracket 22 .

[0098] Preferably, ventilation holes are formed on the plate structure of the extension part 222, so as to reduce wind resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com