Nuclear power pipeline defect detection method based on multi-scale pyramid structure

A pyramid structure and defect detection technology, applied in the pipeline system, neural architecture, character and pattern recognition, etc., can solve the problems of increasing production time cost, consuming a lot of manpower, material and financial resources, and low accuracy, so as to save production time and cost , improve detection efficiency, and quickly identify the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

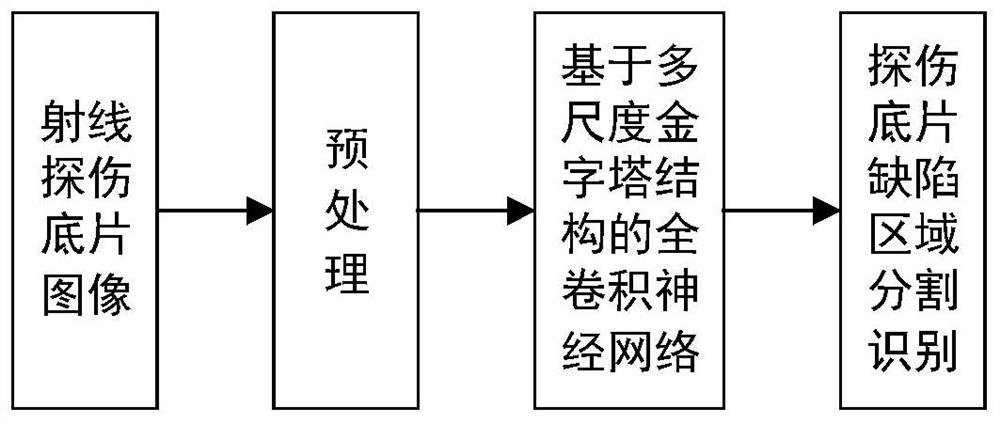

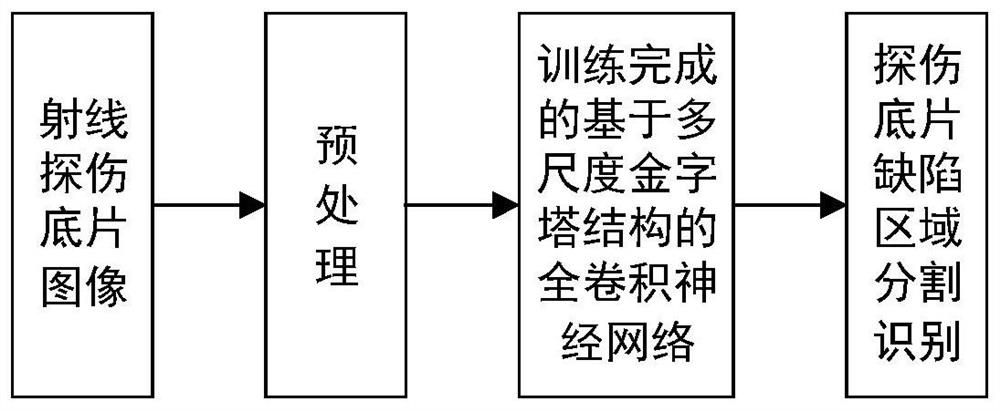

[0013] The method for detecting defects of nuclear power pipelines based on the multi-scale pyramid structure of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0014] The nuclear power pipeline defect detection method based on the multi-scale pyramid structure of the present invention first constructs a training set and a test set after preprocessing by grayscale processing and median filtering, and uses a pyramid network model with multi-scale boosting to perform Training enables the sharing of feature maps of different scales at the same physical scale, refines the segmentation of defect areas, and finally achieves accurate segmentation of defect areas.

[0015] The nuclear power pipeline defect detection method based on the multi-scale pyramid structure of the present invention comprises the following steps:

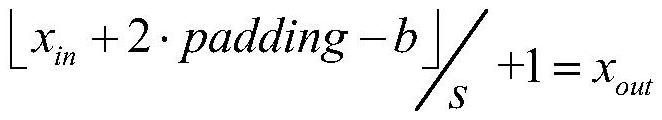

[0016] 1) Preprocessing the image of the radiographic flaw detection film; including:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com