A high-temperature resistant wave-proof cover for aviation

An anti-wave sleeve, high temperature resistant technology, used in power cables, cables, insulated conductors and other directions, can solve the problems of increased use cost, breakdown of the anti-wave sleeve, complicated replacement, etc., to reduce maintenance costs, good shielding effect, Achieve high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

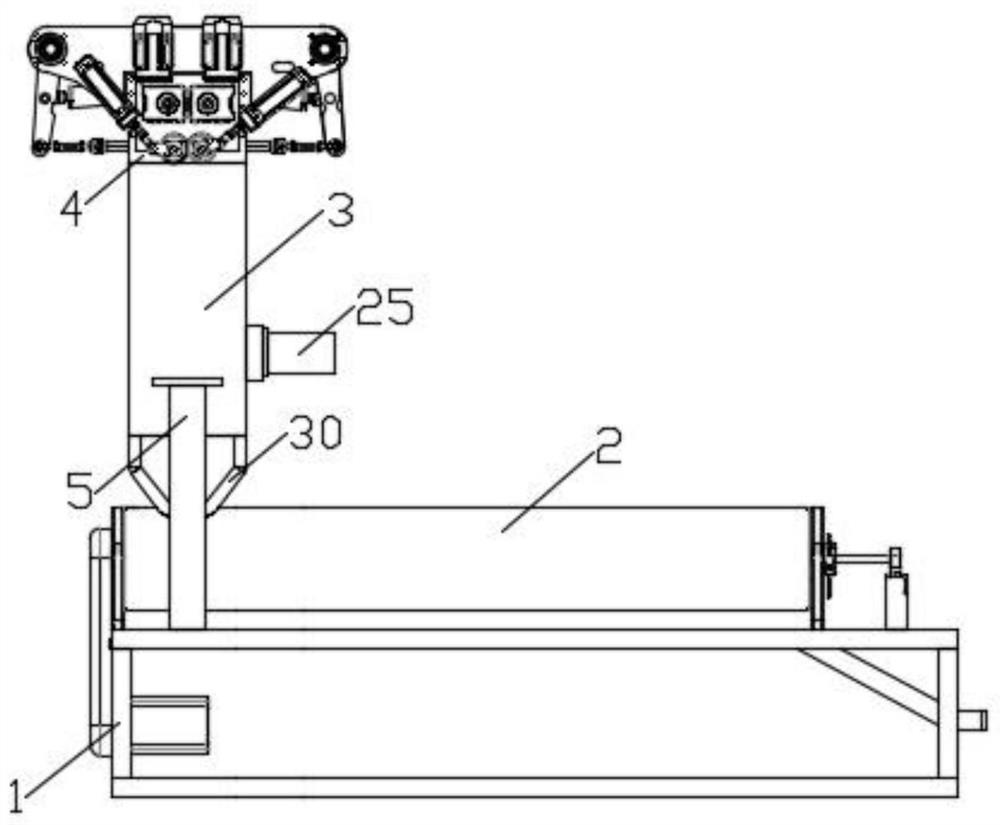

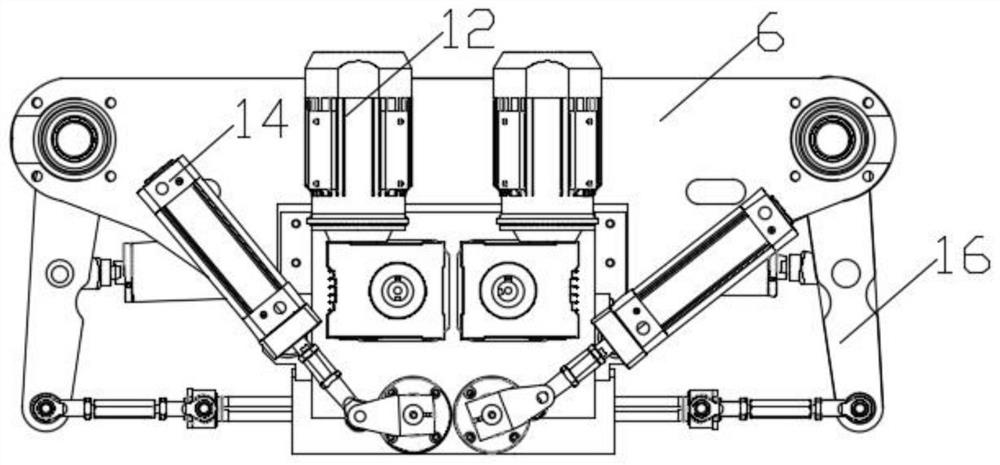

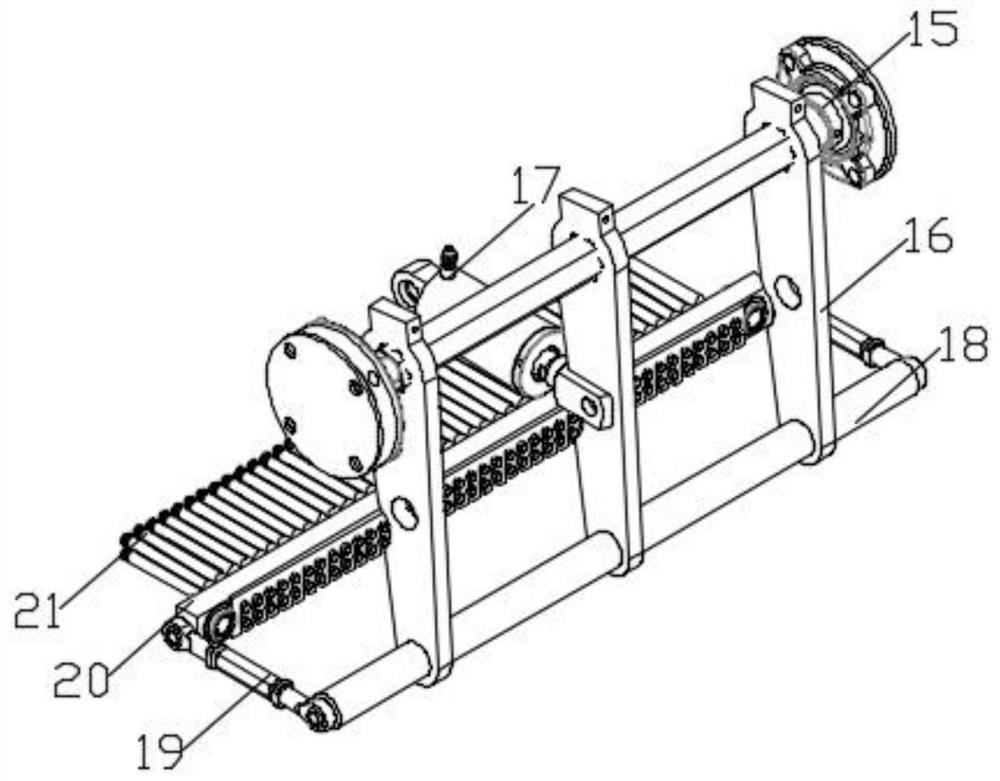

Image

Examples

Embodiment 1

[0032] A high-temperature-resistant wave-proof cover for aviation, the wave-proof cover is woven from a plurality of braided wires, wherein the braided wire is composed of a wire core and a skin attached to the surface layer of the wire core, and the skin is prepared from the following raw materials in parts by weight : 10 parts of nano silicon carbide, 1 part of processing aid, 30 parts of polyethylene resin, 30 parts of epoxy resin, 20 parts of silicone resin, 5 parts of carbon powder, 5 parts of nickel powder;

[0033] Wherein, the preparation process of the high temperature resistant wave shield for aviation is as follows:

[0034] Step 1: Put the epoxy resin and the silicone resin into a high-mixer and mix, and after mixing, the modified epoxy resin is obtained;

[0035] Step 2: Add nano silicon carbide, processing aids, polyethylene resin, modified epoxy resin, carbon powder, and nickel powder into the first-level mixing chamber 7 on the stirring chamber 4 on the process...

Embodiment 2

[0039] A high-temperature-resistant wave-proof cover for aviation, the wave-proof cover is woven from a plurality of braided wires, wherein the braided wire is composed of a wire core and a skin attached to the surface layer of the wire core, and the skin is prepared from the following raw materials in parts by weight : 20 parts of nano silicon carbide, 1.5 parts of processing aids, 50 parts of polyethylene resin, 40 parts of epoxy resin, 30 parts of silicone resin, 10 parts of carbon powder, 10 parts of nickel powder;

[0040] Wherein, the preparation process of the high temperature resistant wave shield for aviation is as follows:

[0041] Step 1: The epoxy resin and the silicone resin are placed in a high-mixer and mixed, and the modified epoxy resin is obtained after mixing; Step 2 is the same as Example 1.

[0042] The silicone resin is polymethyl silicone resin or polyethyl silicone resin, and the particle size of nano-silicon carbide is not more than 100 nm. The polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap