Drive device, electric vehicle, and drive device control method

A driving device and a technology of the control unit, which is applied in the direction of AC motor control, control systems, electrical components, etc., and can solve problems such as the deviation of the installation position of the angle sensor without consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

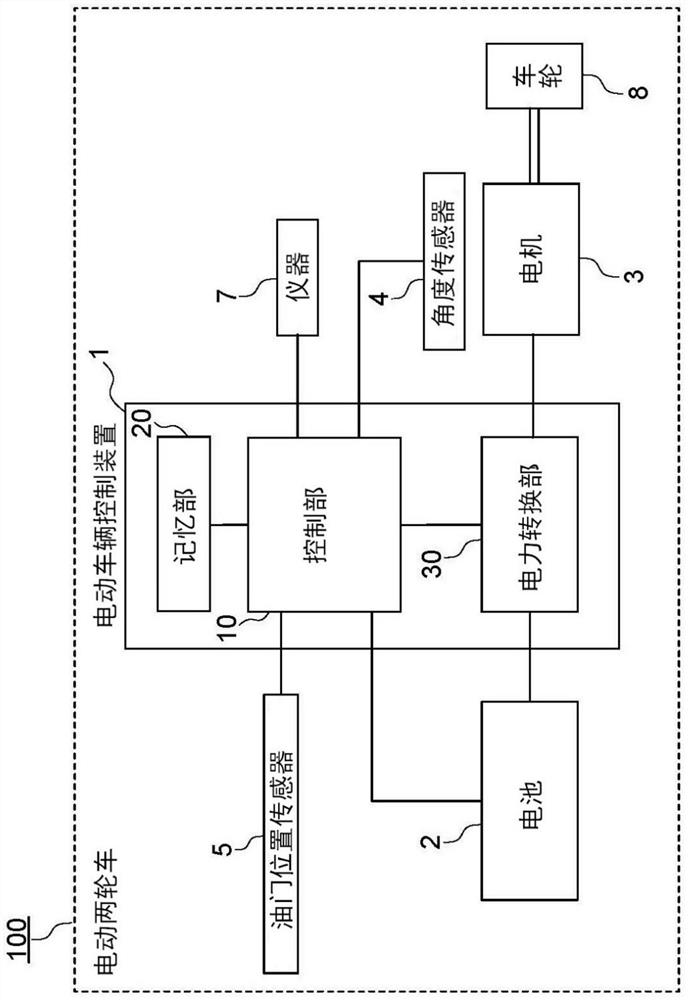

[0113] First, refer to figure 1 An electric two-wheeled vehicle 100 according to the first embodiment as an example of an electric vehicle will be described.

[0114] The electric two-wheeled vehicle 100 is an electric two-wheeled vehicle such as an electric motorcycle that travels by driving a motor using electric power supplied from a battery. Specifically, the electric two-wheeled vehicle 100 is a clutchless electric two-wheeled vehicle in which a motor and wheels are mechanically connected without a clutch.

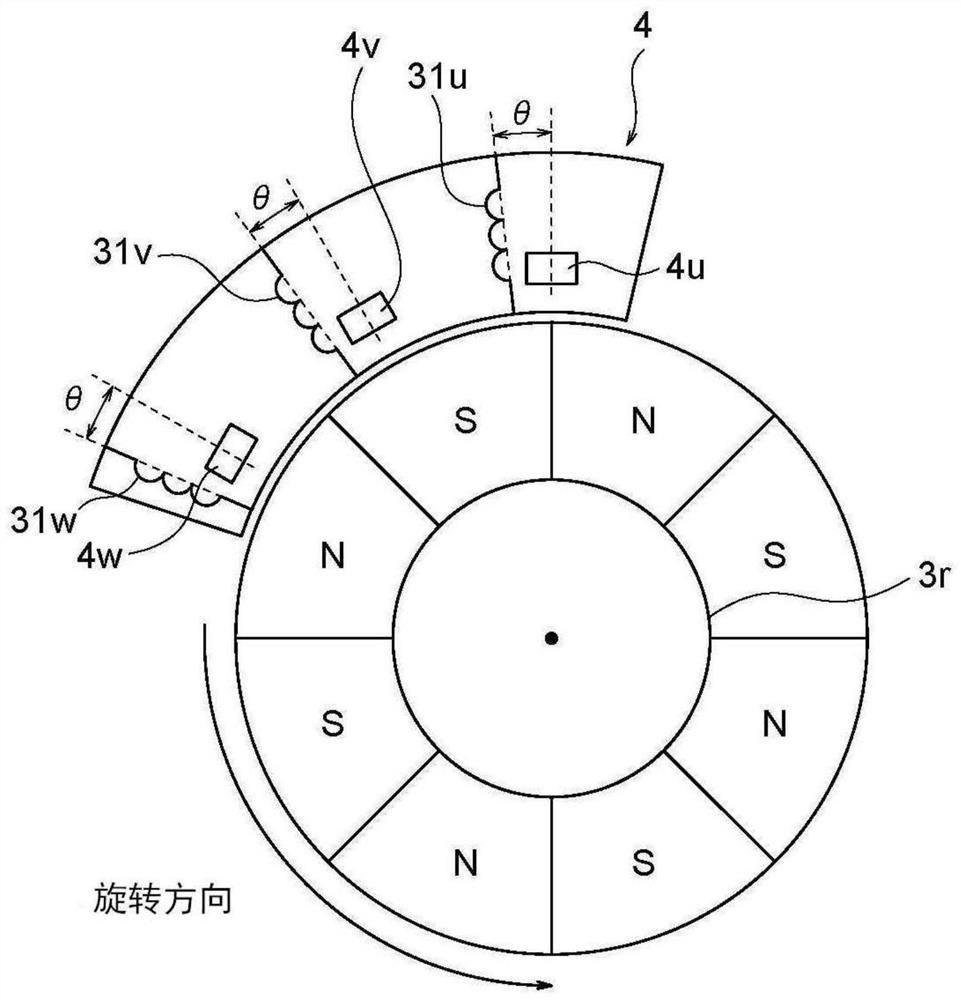

[0115] Electric two-wheeled vehicles 100 such as figure 1 As shown, it includes an electric vehicle control device 1 as an example of a driving device, a battery 2 , a motor 3 , an angle sensor 4 as an example of a rotation speed detection unit, an accelerator position sensor 5 , an instrument 7 , and wheels 8 .

[0116] Next, each component of the electric motorcycle 100 will be described in detail.

[0117] The electric vehicle control device 1 is a device that c...

no. 2 approach

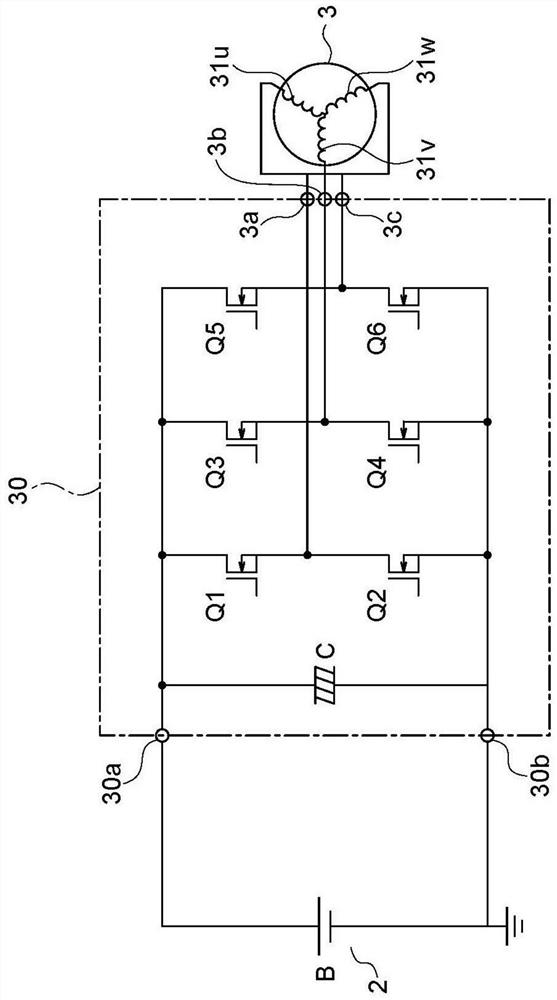

[0211] Next, a second embodiment in which the energization method is selected according to the running state will be described.

[0212] In the second embodiment, in the third case where the detection speed other than the configuration of the first embodiment is slower than the first reference speed, and the set duty ratio is greater than or equal to the first reference duty ratio, the control unit 10. While turning off the second semiconductor switch Q2, the on / off switching control of the first semiconductor switch Q1 is performed by the U-phase high-side PWM signal (ie, the first-phase high-side PWM signal) with a set duty ratio.

[0213] In addition, when in the third situation, the control unit 10 turns off the fourth semiconductor switch Q4, while passing the V-phase high-side PWM signal (that is, the second-phase high-side PWM signal) with a set duty ratio to the third semiconductor switch Q3. ON / OFF switching control.

[0214] In addition, when in the third situation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com