Device for pushing granular hemostatic to relatively deep wound

A hemostatic agent and wound technology, applied in the field of medical first aid, can solve problems such as difficulty in pushing out, poor rigidity of the front end of the device, failure to achieve the purpose of first aid, etc., and achieve the effect of ensuring smooth injection, full play, and completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

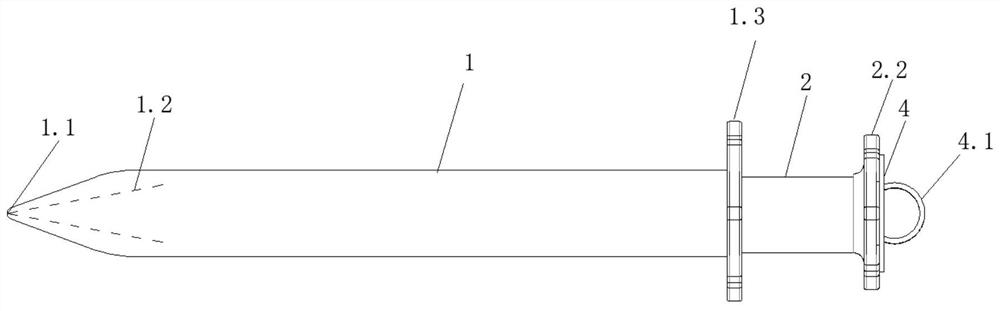

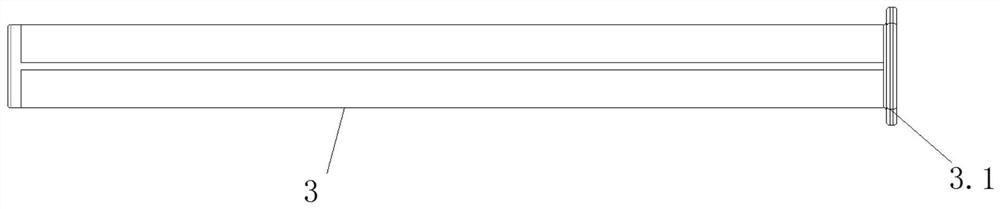

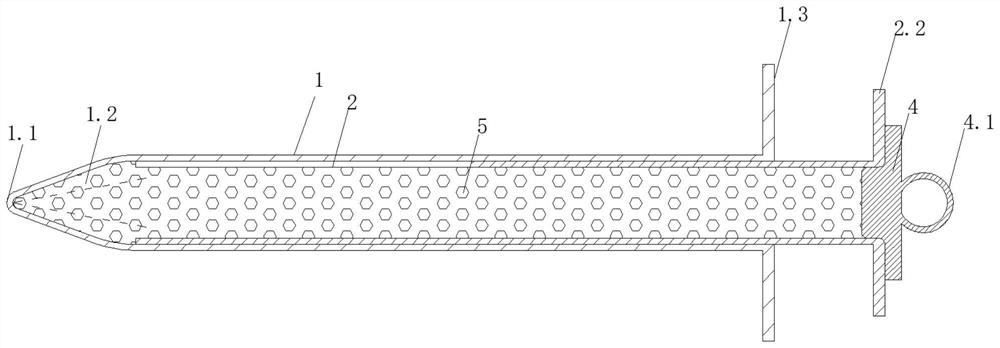

[0035] Such as figure 1 , figure 2 As shown, it is a specific embodiment of the present invention, which includes an inner and outer double-layer cylindrical cylinder (outer cylinder 1, inner cylinder 2), an inner cylinder plug 4, and a bolus rod 3.

[0036] Such as image 3 As shown, the inner diameter of the outer cylinder 1 is consistent with the outer diameter of the inner cylinder 2, and the two cooperate with each other. The inner cylinder 2 and the outer cylinder 1 can slide relative to each other. A cavity is formed, which accommodates the hemostatic agent 5 . The front end of the outer cylinder 1 is closed and the rear end is open; both ends of the inner cylinder 2 are open; the rear end of the inner cylinder is provided with a plug 4, the outer diameter of the plug and the inner cylinder The inner diameters of the body are consistent, and are used to seal the hemostatic agent 5 in the cavity. The plug 4 is also provided with a pull ring 4.1, which is convenient ...

Embodiment 2

[0041] Such as Figure 6 As shown, on the basis of Embodiment 1, further, a movable limit assembly clamp 6 is provided on the outer wall of the inner cylinder body 2, which is used to fix the relative distance between the inner cylinder body and the inner cylinder body and prevent the inner cylinder body from moving during transportation. , Destroying the sealing of the front valve body.

[0042] Shown limit assembly clip 6 is made up of two parts, as Figure 7 As shown, 6.1 is the limit clamp of the inner cylinder, which is installed on the outer wall of the inner cylinder 2, and has a certain width so that the inner and outer cylinders will not slide. The combination cylinder and injection rod are assembled together for convenient packaging and transportation.

[0043] Such as Figure 6 As shown, when the present invention is used, first remove the injection rod 3 stuck on the combined cylinder, align the discharge end 1.1 and insert it into the wound, and after reaching ...

Embodiment 3

[0045] Another embodiment of the present invention is Figure 8 As shown, on the basis of Examples 1 and 2, further, the end of the petal body of the outer cylinder is provided with a drop-shaped opening 1.4 to make the petal body easier to open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com