High-pressure fluid extraction separator

A high-pressure fluid and separator technology, applied in solvent extraction, separation methods, liquid solution solvent extraction, etc., can solve the problems of difficult control of heating temperature, reduced separation effect, and blockage of discharge pipes, so as to reduce cleaning labor and prolong The effect of flow time and increase in usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

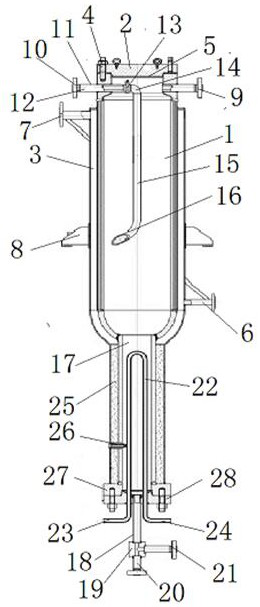

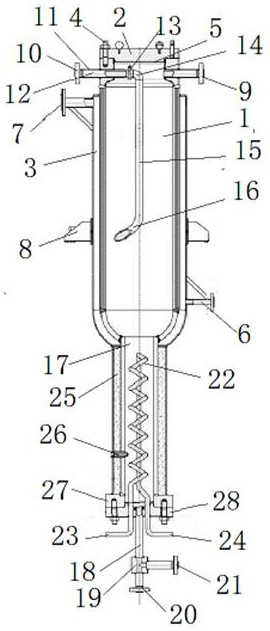

[0028] see figure 1 , a high-pressure fluid extraction separator, comprising a kettle body 1, a kettle cover 2 arranged at the top of the kettle body 1 and a jacket 3 wrapped on the outer wall of the kettle body 1, the kettle body 1 and the kettle cover 2 are connected by bolts 4, and the A sealing ring 5 is provided at the joint with the kettle cover 2, which can improve the tightness of the kettle body 1, and prevent the supercritical fluid containing the extracted substance from escaping from the connection between the kettle cover 2 and the kettle body 1, resulting in low extraction rate and clamping. The jacket 3 is provided with a water inlet 6 and a water outlet 7, through the water inlet 6, input hot water into the jacket 3 to heat the kettle body 1, so that the supercritical fluid in the kettle body 1 becomes a gas and separates from the extracted substance , The outer wall of the jacket 3 is provided with a support 8 .

[0029] Both sides of the upper part of kettle...

Embodiment 2

[0040] see figure 2 , The difference between this embodiment and Embodiment 1 is that: the hot water pipe 22 is a coil, and other structures are the same as Embodiment 1.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is that: the hot water pipe 22 is a spiral pipe, and other structures are the same as Embodiment 1.

[0043] Changes in the above technical features can be understood and implemented by those skilled in the art through written descriptions, so no additional drawings are provided for illustration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com