Continuous emulsification desorption type adsorption netting for oil mist-containing waste gas

A waste gas and desorption technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of limited usability, can not completely solve the problem of oily waste gas treatment, affecting the effect of adsorption and filtration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

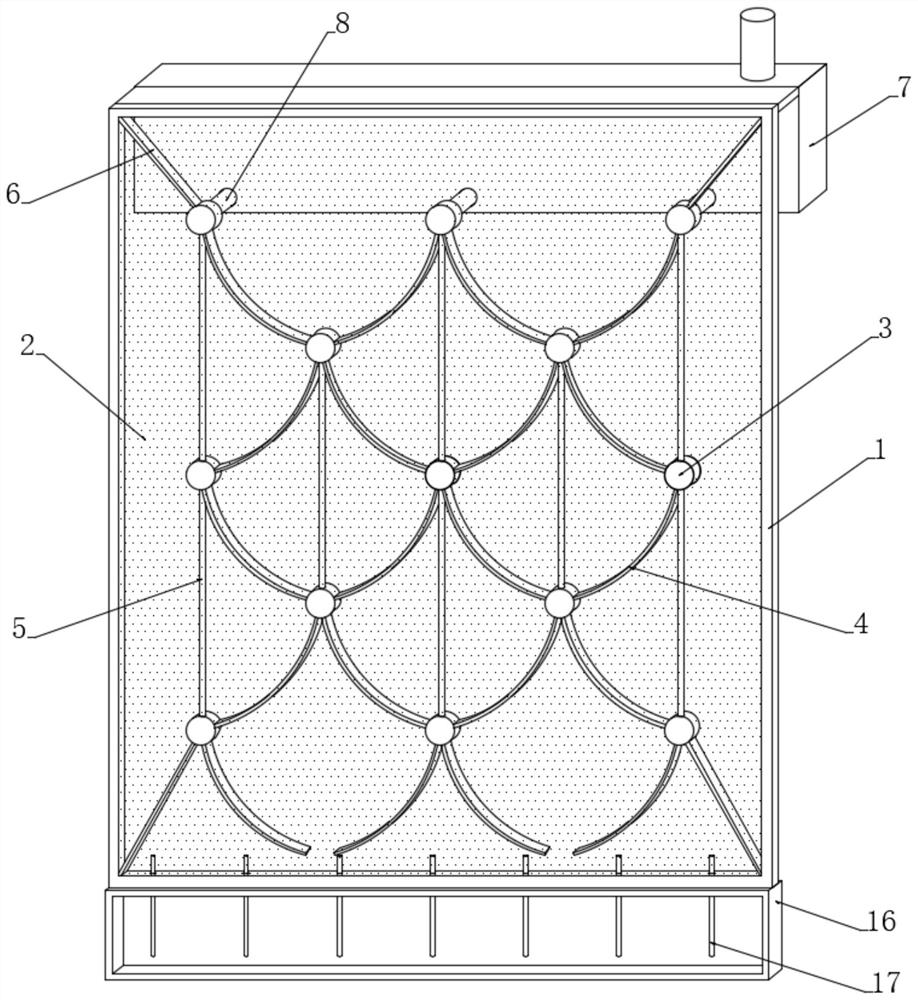

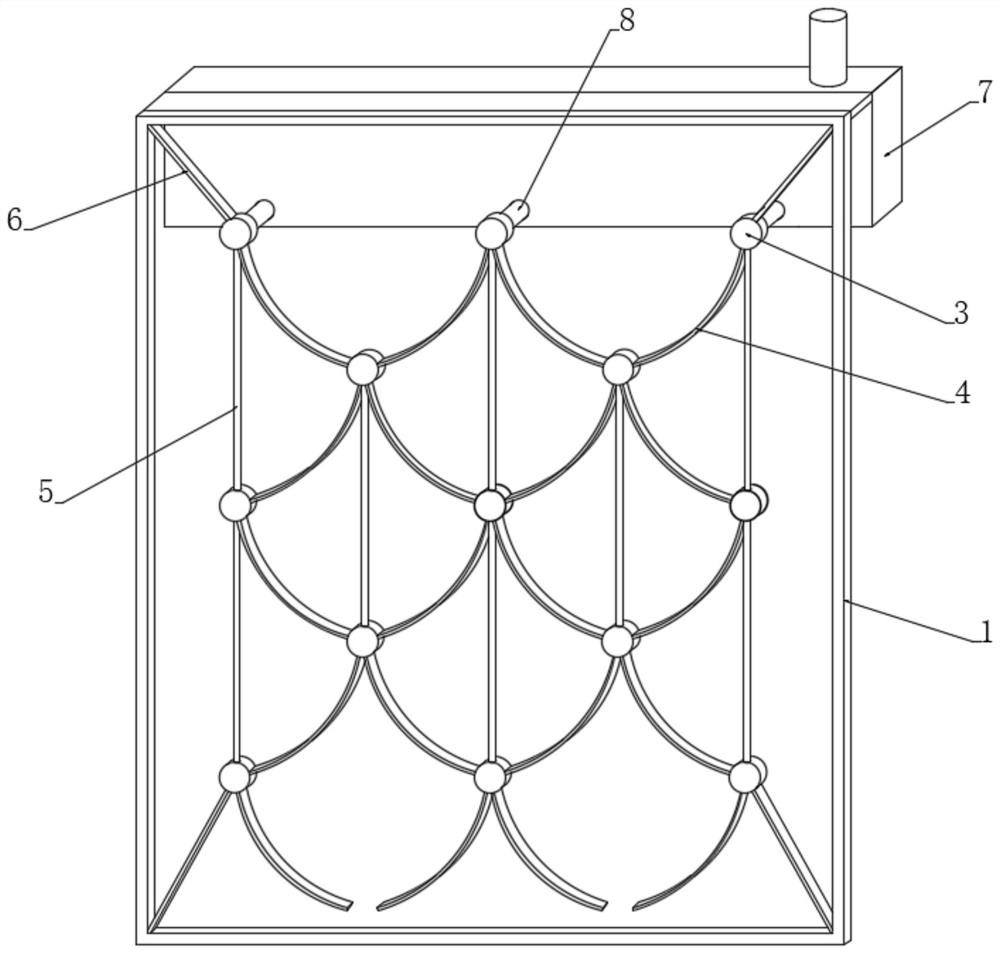

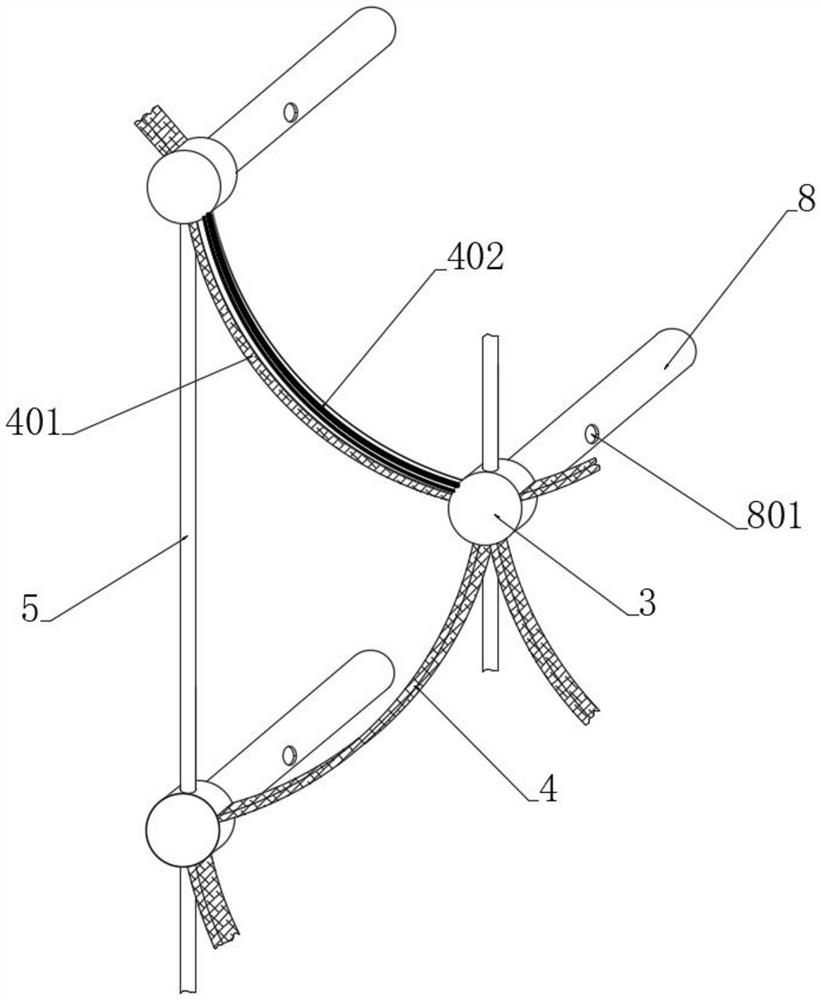

[0037] see Figure 1-5 , a continuous emulsification and desorption adsorption network for exhaust gas containing oil mist, including a filter frame 1 and a fiber filter screen 2 embedded in the filter frame 1, an emulsification flow guide mechanism is installed inside the filter frame 1, and the emulsification flow guide The mechanism is embedded and connected with the fiber filter screen 2, and the top side of the filter frame 1 is fixedly connected with a storage box 7 communicating with the top end of the emulsification flow guide mechanism. The emulsification flow guide mechanism includes a plurality of The emulsification diversion heads 3, the upper and lower adjacent emulsification diversion heads 3 are connected through the capillary 5, and the emulsification diversion heads 3 that are adjacent to each other up and down are connected by the arc-shaped diversion fiber body 4, and the arc Shape guide fiber body 4 comprises the hollow filter plate 401 that is connected be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com