A preparation method and application of a 0d/1d/2d composite magnesium-aluminum double metal oxide nanocatalytic material

A technology of bimetallic oxides and nanocatalytic materials, which is applied in the preparation of metal/metal oxide/metal hydroxide catalysts, organic compounds, catalyst activation/preparation, etc. The active sites on the surface of dimensional materials are easily covered, so as to achieve the effect of improving the catalytic ability, low cost and high catalytic efficiency of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

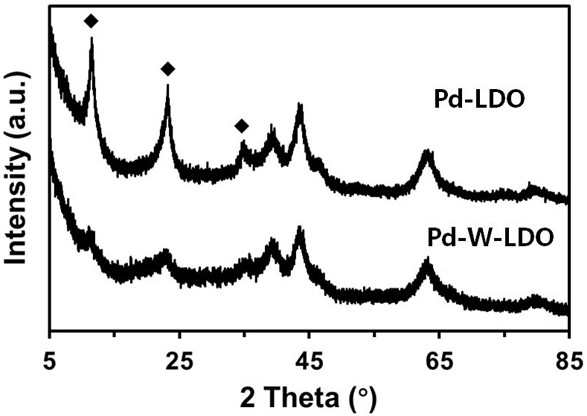

[0050] Preparation of Pd-W-LDO nanocatalytic materials:

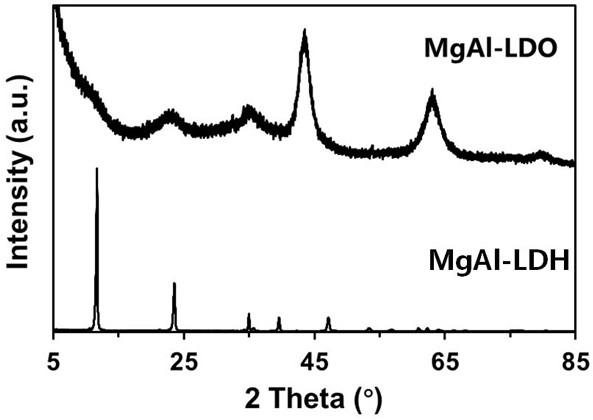

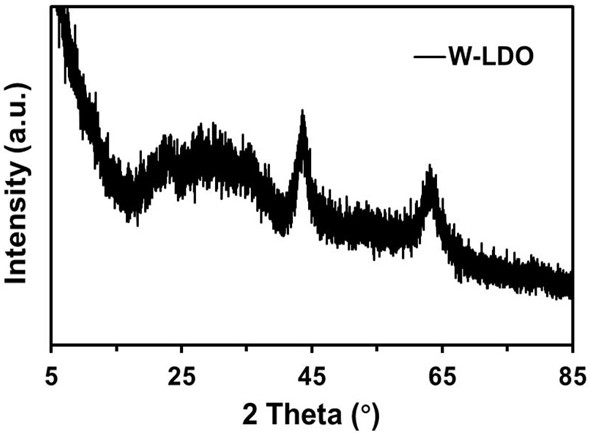

[0051] (1) Add magnesium chloride hexahydrate (70 mmol) and aluminum chloride hexahydrate (35 mmol) with a molar ratio of Mg / Al=2:1 into 50 mL of deionized water, stir until completely dissolved to obtain magnesium-aluminum mixed salt solution. Then add urea (25 mmol) to the magnesium-aluminum mixed salt solution and stir until completely dissolved. Pour the obtained colorless and clear mixed solution into a polytetrafluoroethylene reactor liner with a capacity of 100 mL, then place the liner in the stainless steel shell of the reaction kettle to seal it, place it in an oven to keep warm, and set the temperature rise rate of the oven to be 5°C / min, the holding temperature was 120°C, the holding time was 24 h, then cooled to room temperature, the white precipitate at the bottom was taken out, collected by centrifugation, washed 4 times with deionized water, and placed in a freeze dryer at -53°C to freeze dry 12 h, obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com