File plastic packaging machine

A packaging machine and plastic sealing machine technology, applied in the field of packaging equipment, can solve the problems of inability to scan and save file contents, inability to align shrink films, and inability to classify packaging, etc., to shorten replacement time, facilitate packaging, and improve packaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

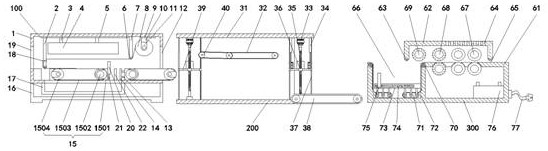

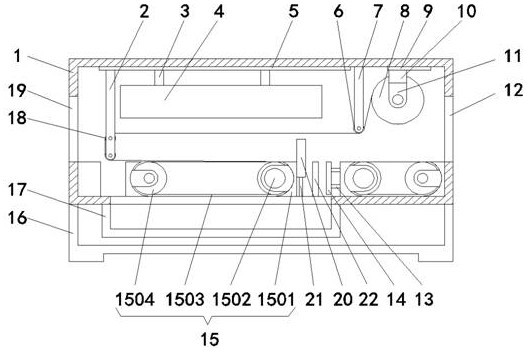

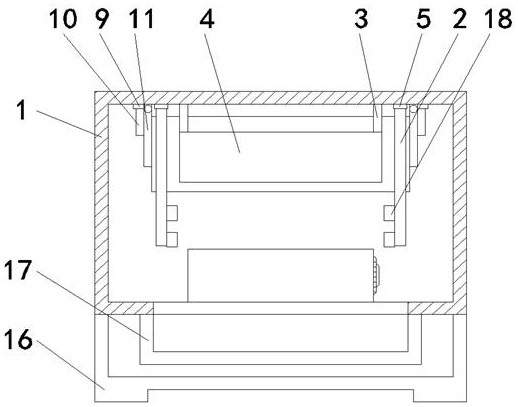

[0051] The embodiments of the present invention provide a document plastic sealing and packaging machine, which aims to solve the problem that the shrink film of the current document plastic sealing and packaging machine cannot be aligned, cannot be automatically sorted and packaged according to the number of document pages, cannot scan the contents of the document and save the file, and easily enters the air when the document is sealed. , the plastic seal is prone to folds and other problems.

[0052] By arranging a fixed rod, a sliding rod and a clamping block inside the shell of the film supply mechanism, and by installing a shrink film, the shrink film is stretched by the fixed rod and the sliding rod to form a double-layer film structure, which can solve the problem of two films. The problem of non-alignment also improves the speed of plastic sealing and enhances the effect of plastic sealing.

[0053] The threaded rod is driven to rotate by the first drive motor of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com