Canning assembly line

An assembly line and canning technology, which is applied in the field of canning, can solve the problems of sufficient gas content, anti-foaming, and large amount of foam in the can, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

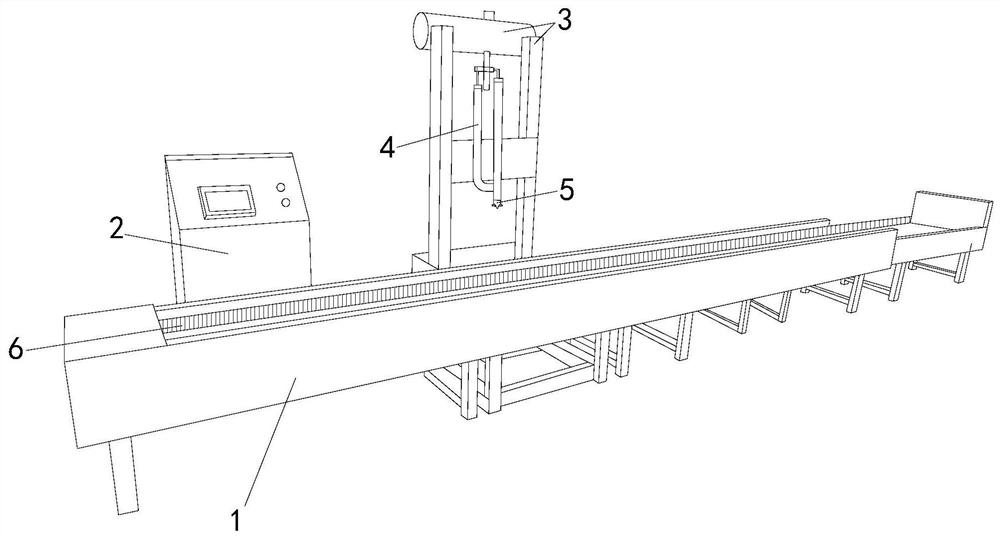

[0024] see figure 1 , the present invention provides a kind of canning assembly line, its structure comprises: Canning frame 1, numerical control table 2, liquid inlet tank 3, liquid injection pipe 4, defoaming pipe mechanism 5, rotary belt 6, described canning frame 1 is equipped with a numerical control platform 2 and a liquid inlet tank 3 respectively. The liquid inlet tank 3 is connected to the liquid injection pipe 4. The bottom end of the liquid injection pipe 4 is provided with a defoaming pipe mechanism 5. On the side, the canning frame 1 is the basic frame structure of the assembly line equipment, and it is also the conveying structure responsible for conveying empty cans to the carbonated beverage liquid raw material position for canning. Its structure presents a rectangular box structure with an unclosed top, with two sides The conveying member is composed of a rotary belt 6, the electronic cabinet structure with 2 digits of the numerical control table is used to c...

Embodiment 2

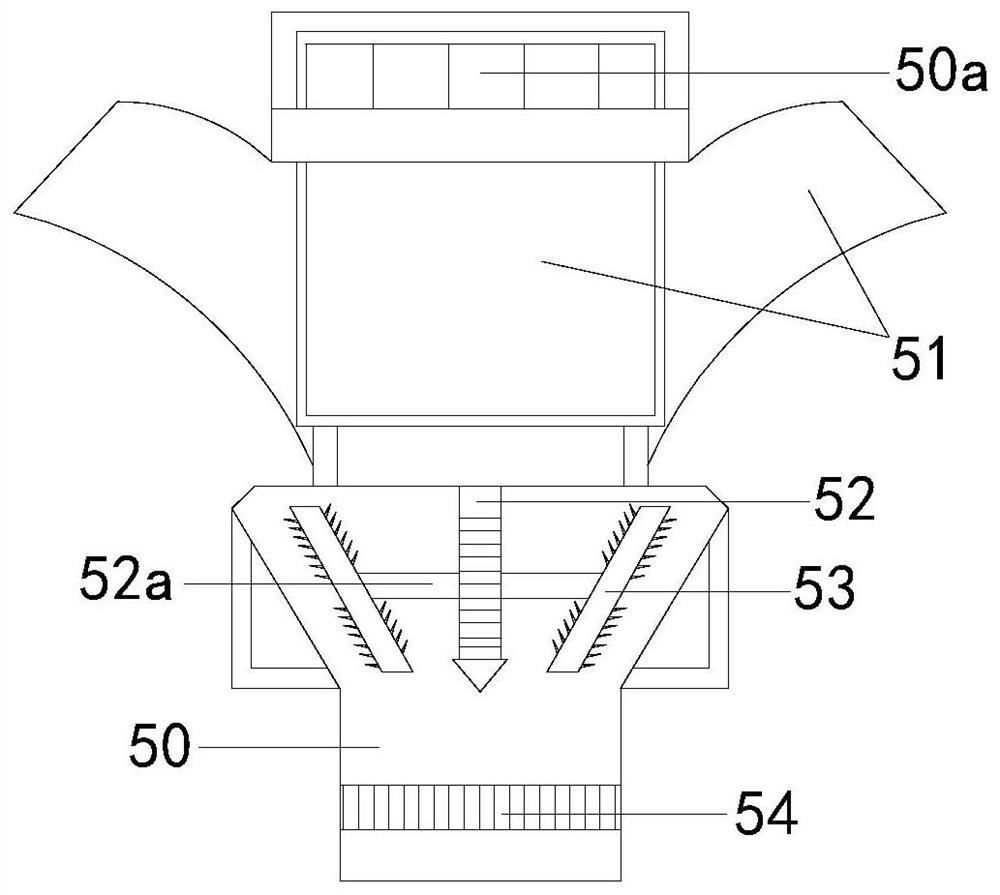

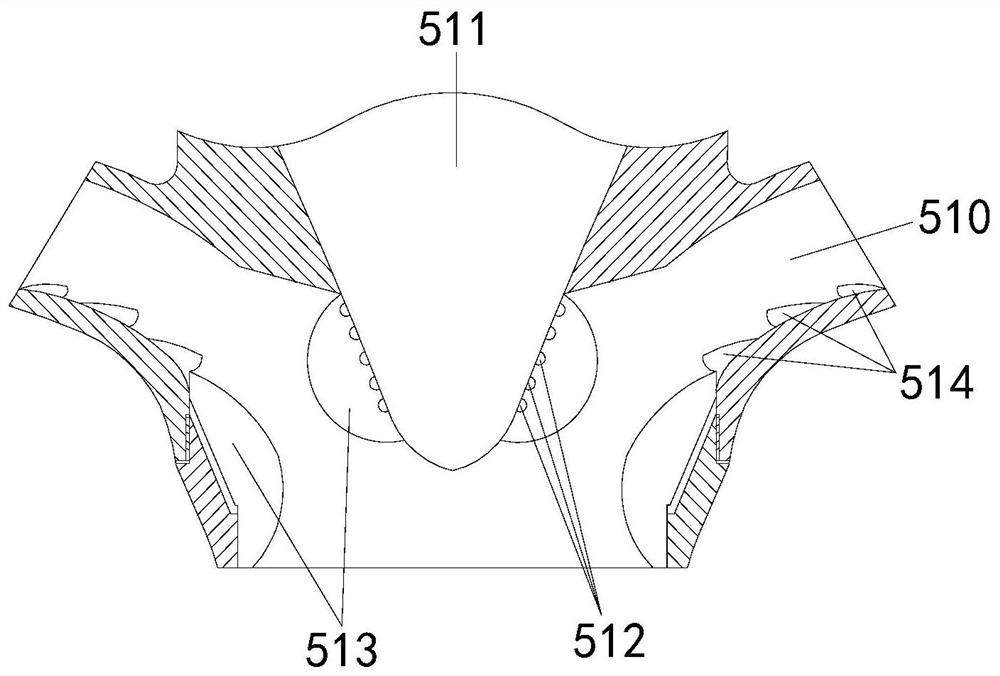

[0031] The description of the second embodiment drawn in conjunction with the first embodiment, combined with image 3 , Figure 4 and Figure 5 An air plunger 511 is provided between the elbow pipe walls 510, and the air plunger 511 communicates with the closed bag 513 through the provided air hole 512, and the side of the closed bag 513 is arranged with stop blocks 514, and the half Both sides of the shaft 530 are connected to the vibrating plate 531, and the side edge of the vibrating plate 531 is provided with penetrating teeth 532, and the penetrating ball 540 is connected to the bubble ball 542 through the rod joint 541, and the bottom end of the bubble ball 542 is provided with dense teeth When the cone 543 is filled, the liquid injection pipe 4 is first aligned with the empty beverage can. At this time, the liquid is conveyed downward, and the defoaming pipe mechanism 5 performs defoaming work synchronously. The vibrating plate 531 vibrates and simultaneously drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com