Tensioning device, hot bending mechanism and hot bending machine

A tensioning device and tensioning shaft technology, applied in the fields of tensioning device, hot bending mechanism and hot bending machine, can solve the problems of difficult hot bending, glass deformation, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present disclosure, but not to limit the present disclosure.

[0037] In the present disclosure, unless otherwise stated, the directional words used such as "upper and lower" generally refer to the definition based on the drawing direction of the drawings, and the used terms such as "first, second" Two" etc. are only to distinguish one element from another, and do not have order and importance.

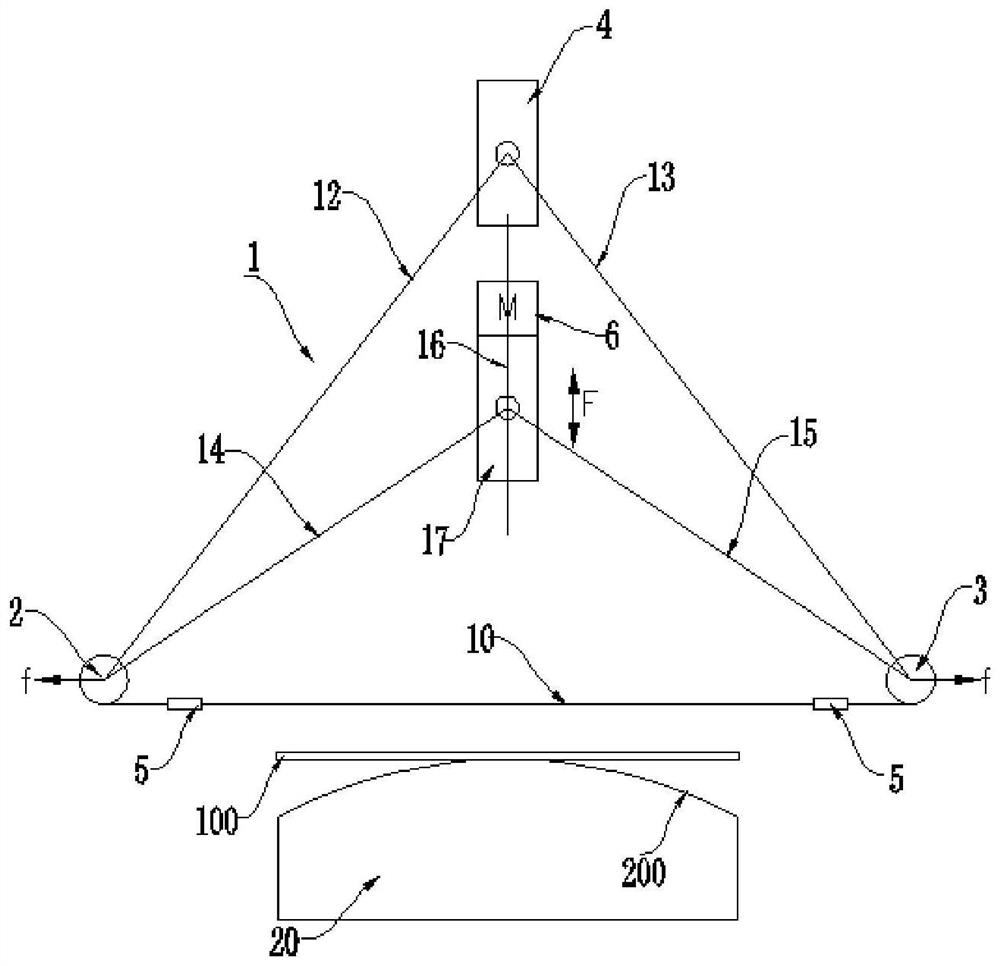

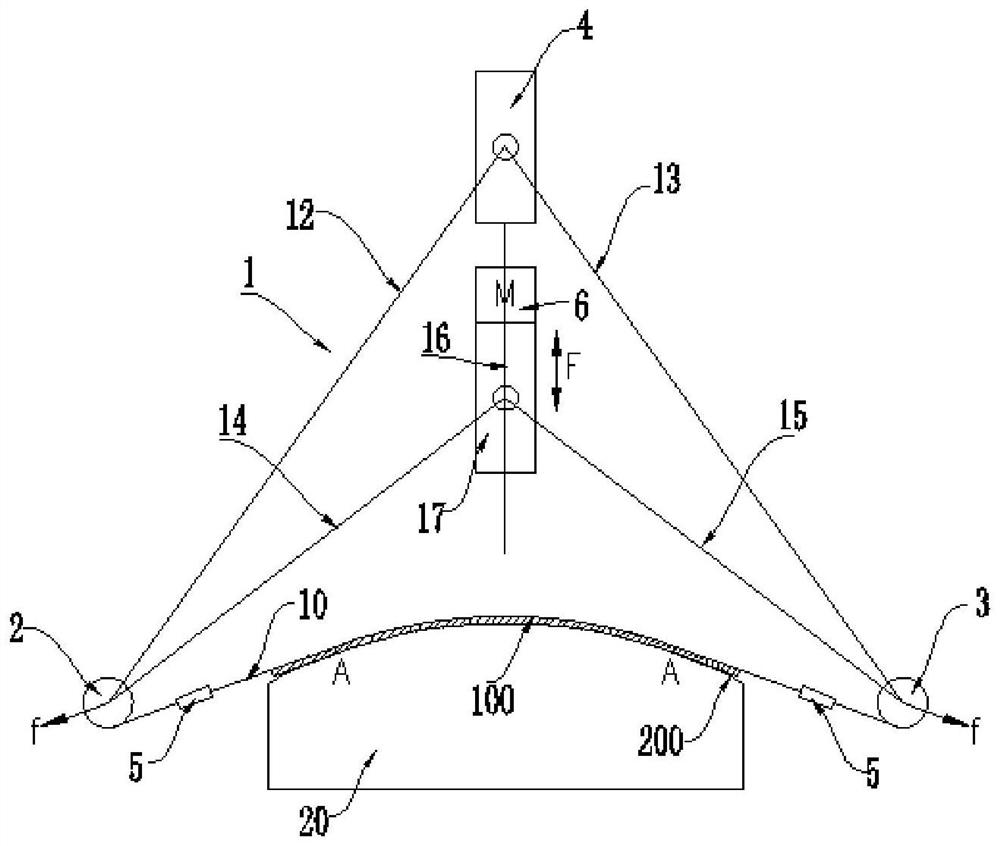

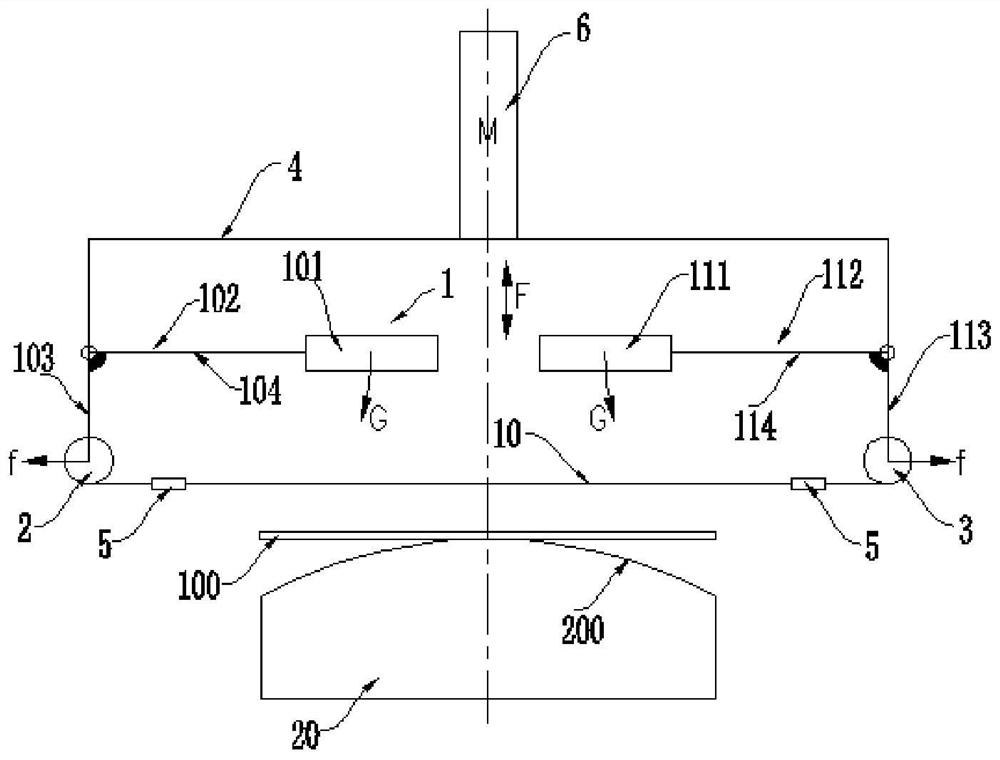

[0038] like Figure 1 to Figure 4As shown, the present disclosure provides a tensioning device, which includes a driving unit 1, a first tensioning shaft 2 and a second tensioning shaft 3 that are spaced apart and oppositely arranged, the first tensioning shaft 2 and the second tensioning shaft 3 The tightening shaft 3 is used to fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com