Warm-keeping fabric and preparation process thereof

A preparation process and fabric technology, applied in the direction of weaving, fiber type, dyeing method, etc., can solve the problems of affecting the wearing comfort of textiles, insufficient thermal performance, and short service life, so as to improve processing production efficiency and improve wearing quality. The effect of comfort and skin-friendliness, best weaving tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

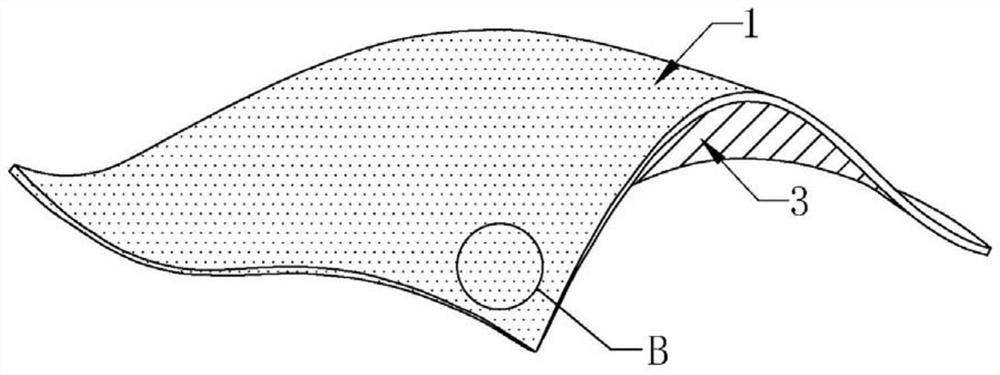

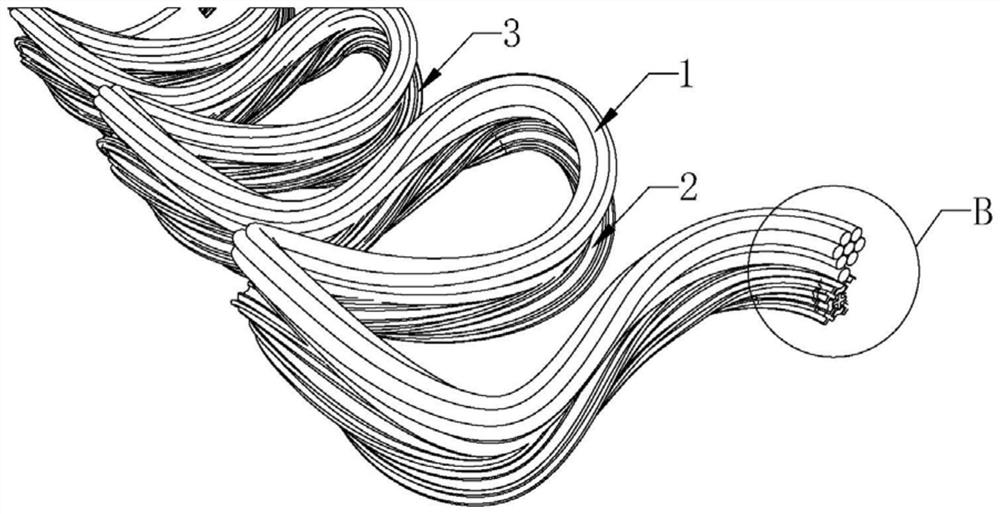

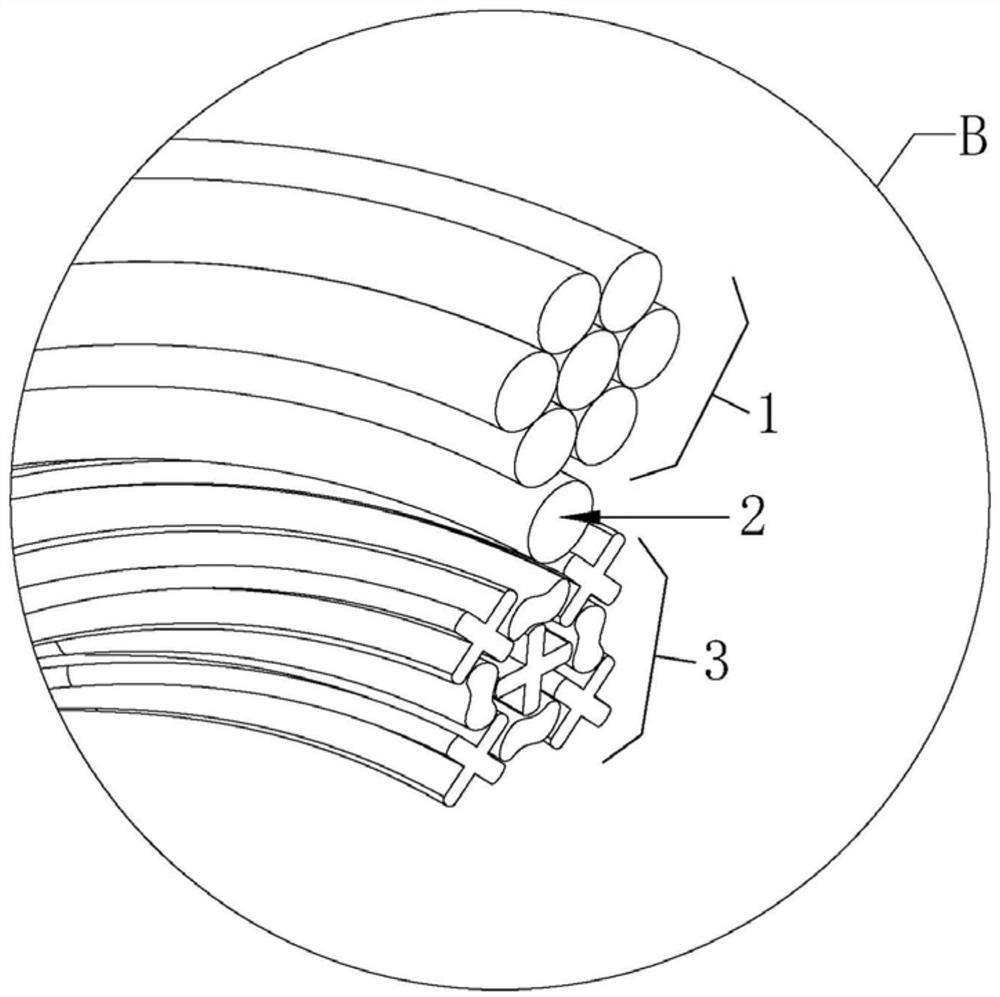

[0060] See Figure 1-3 , a kind of thermal fabric, this thermal fabric is woven by composite yarn, and described composite yarn is formed by stacking veil 1, elastic fiber yarn 2 and ground yarn 3, and described veil 1 forms surface layer after lamination molding, and described elastic The fiber yarn 2 forms the elastic middle layer and the ground yarn 3 forms the bottom layer.

[0061] The veil 1 is a wool fiber with a common count of 1 / 80Nm and a count of 90S; the elastic fiber yarn 2 is a low-temperature spandex with a denier of 33D; 50S / 1 polypropylene fiber, 15% modal fiber and 2% graphene fiber are blended.

[0062]The yarn length density of the veil 1 is 26cm / 100g, the yarn length density of the elastic fiber yarn 2 is 13.5cm / 100g, and the yarn length density of the ground yarn 3 is 25cm / 100g.

[0063] A preparation process for the above-mentioned thermal fabric, comprising the steps of:

[0064] A, weaving: the veil 1, the elastic fiber yarn 2 and the bottom yarn 3 ...

Embodiment 2

[0085] See Figure 1-3 , a kind of thermal fabric, this thermal fabric is woven by composite yarn, and described composite yarn is formed by stacking veil 1, elastic fiber yarn 2 and ground yarn 3, and described veil 1 forms surface layer after lamination molding, and described elastic The fiber yarn 2 forms the elastic middle layer and the ground yarn 3 forms the bottom layer.

[0086] The veil 1 is a wool fiber with a common count of 1 / 80Nm and a count of 90S; the elastic fiber yarn 2 is a low-temperature spandex with a denier of 55D; 60S / 1 polypropylene fiber, 15% modal fiber and 0.8% graphene fiber are blended.

[0087] The yarn length density of the veil 1 is 28cm / 100g, the yarn length density of the elastic fiber yarn 2 is 12cm / 100g, and the yarn length density of the ground yarn 3 is 28cm / 100g.

[0088] A preparation process for the above-mentioned thermal fabric, comprising the steps of:

[0089] A, weaving: the veil 1, the elastic fiber yarn 2 and the bottom yarn 3...

Embodiment 3

[0111] See Figure 1-3 , a kind of thermal fabric, this thermal fabric is woven by composite yarn, and described composite yarn is formed by stacking veil 1, elastic fiber yarn 2 and ground yarn 3, and described veil 1 forms surface layer after lamination molding, and described elastic The fiber yarn 2 forms the elastic middle layer and the ground yarn 3 forms the bottom layer.

[0112] The veil 1 is a wool fiber with a common count of 1 / 80Nm and a count of 90S; the elastic fiber yarn 2 is a low-temperature spandex with a fineness of 33D; 50S / 1 polypropylene fiber, 14% modal fiber and 2% graphene fiber are blended.

[0113] The yarn length density of the veil 1 is 30cm / 100g, the yarn length density of the elastic fiber yarn 2 is 13cm / 100g, and the yarn length density of the ground yarn 3 is 30cm / 100g.

[0114] A preparation process for the above-mentioned thermal fabric, comprising the steps of:

[0115] A, weaving: the veil 1, the elastic fiber yarn 2 and the bottom yarn 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com