A road maintenance snow melting salt automatic spraying guardrail

An automatic spraying and road maintenance technology, applied in the directions of roads, roads, road safety devices, etc., can solve the problem of untimely spreading and other problems, and achieve the effect of ensuring normal sliding, avoiding traffic congestion and avoiding traffic accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

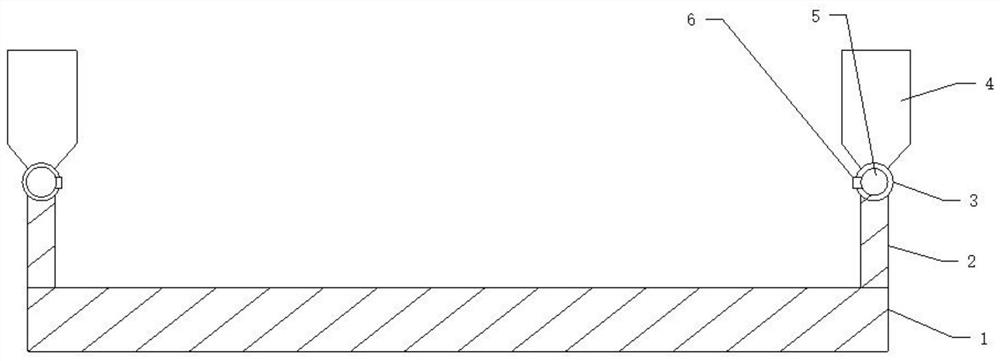

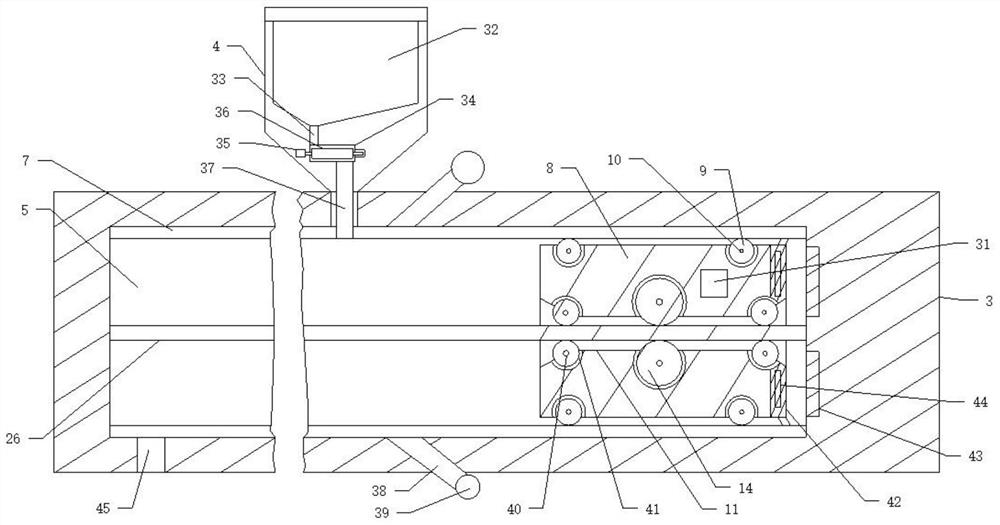

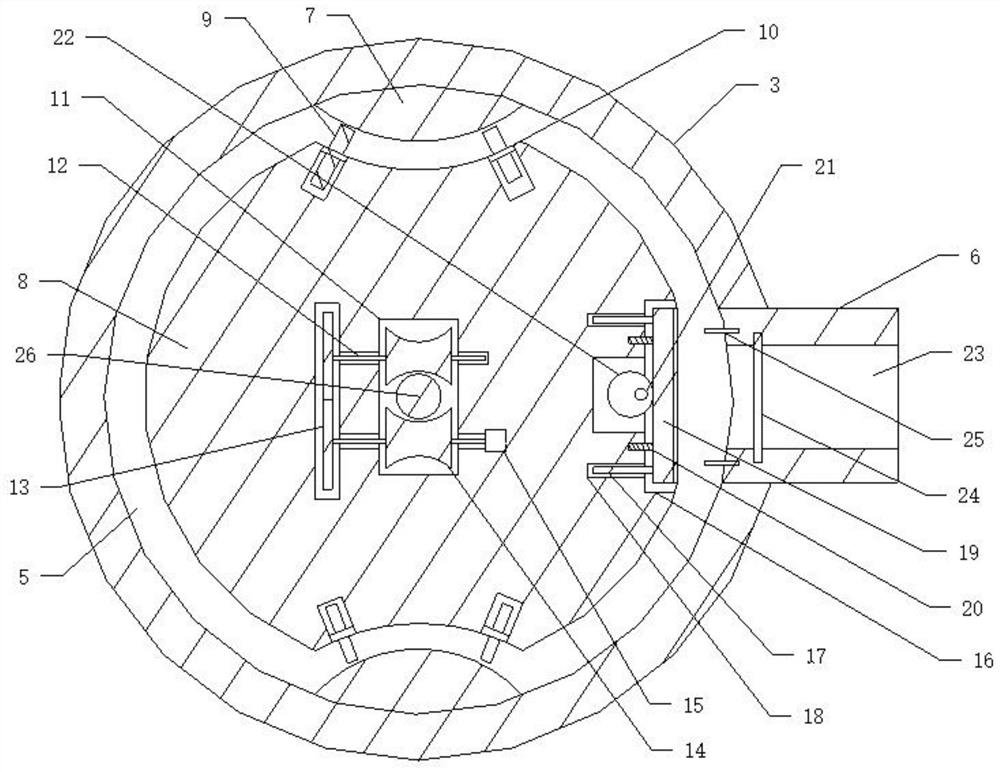

[0037] Such as Figure 1 to Figure 5 As shown, a road maintenance snow-melting salt automatic spraying guardrail includes a road surface 1, and the two sides of the road surface 1 are respectively provided with supporting railings 2 arranged side by side, and the supporting railings 2 are provided with series-connected horizontal railings 3. A railing inner cavity 5 is arranged in the railing 3, and a plurality of sprinkler heads 6 are respectively arranged on the horizontal railing 3, and the sprinkler heads 6 on both sides correspond to the road surface 1 respectively, and the ends of the horizontal railing 3 are provided with storage Barrel 4.

[0038]Both sides of the road surface 1 are respectively provided with supporting railings 2 arranged side by side, and a horizontal railing 3 is arranged on the top of the supporting railing 2, and a railing cavity 5 is arranged in the horizontal railing 3, and the quantity of the horizontal railing 3 is set according to the road. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com