Ground anti-seismic deformation joint structure and construction method thereof

A deformation joint and ground technology, applied in building structures, building components, building insulation materials, etc., can solve the problems of poor combination of surface decoration materials and seismic isolation deformation joints, large deformation joint width, and high repair cost. Achieve the effect of high construction efficiency, large deformation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

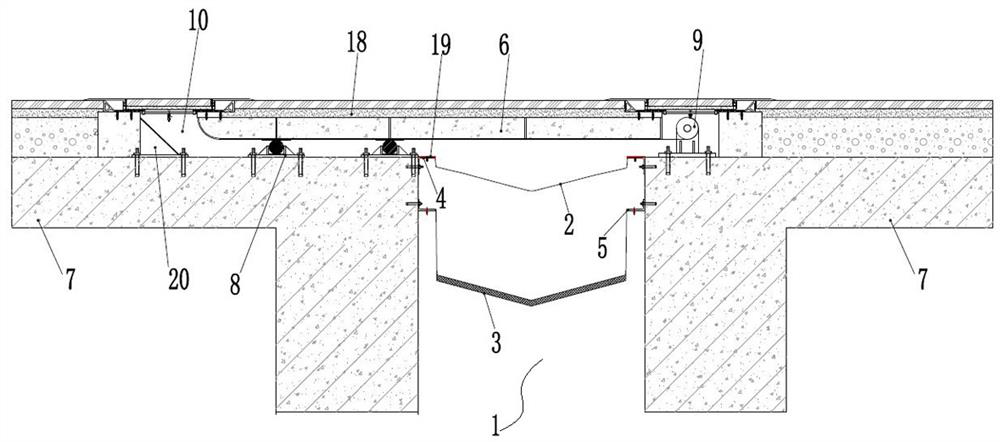

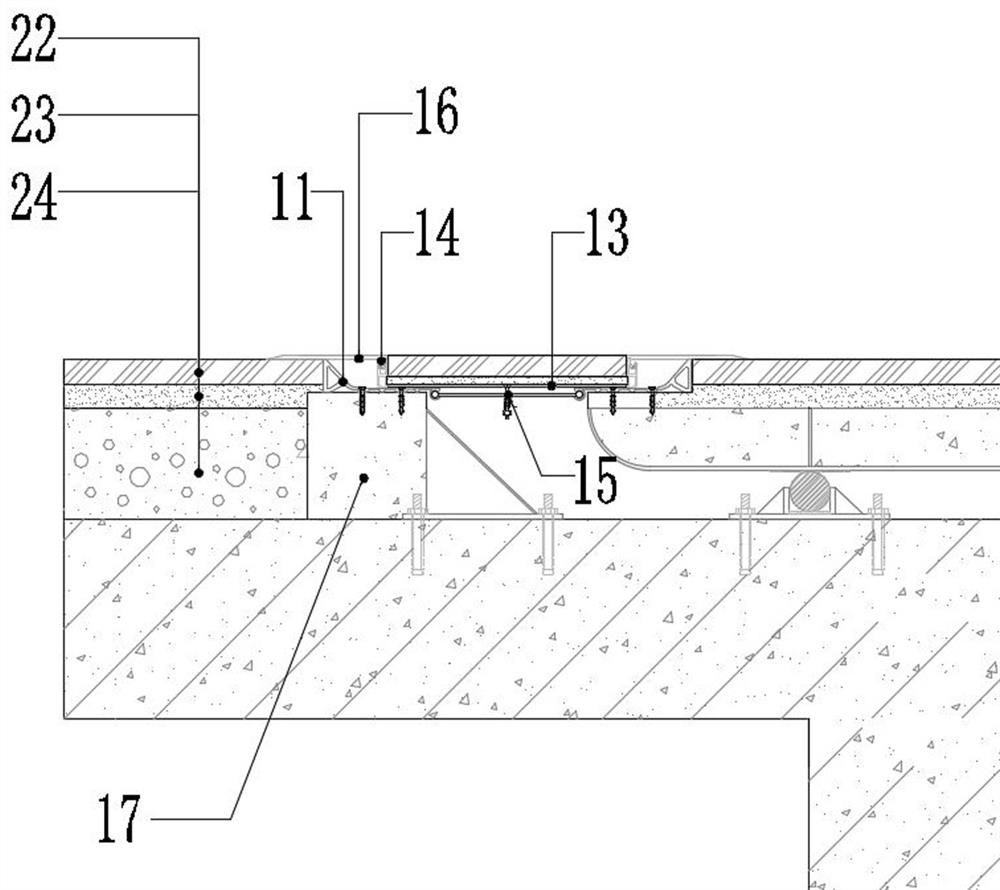

[0069] The invention provides a ground seismic deformation joint structure and a construction method thereof, which has simple structure, easy connection and convenient construction, and overcomes the limitation that the maximum width of the traditional deformation joint is 500mm. It is suitable for super-long concrete structures, the width of the deformation joints reserved for the structure is 800-1200mm, and the deformation amount of the deformation joints is 250-550mm. It can be used in the construction of seismic isolation deformation joints.

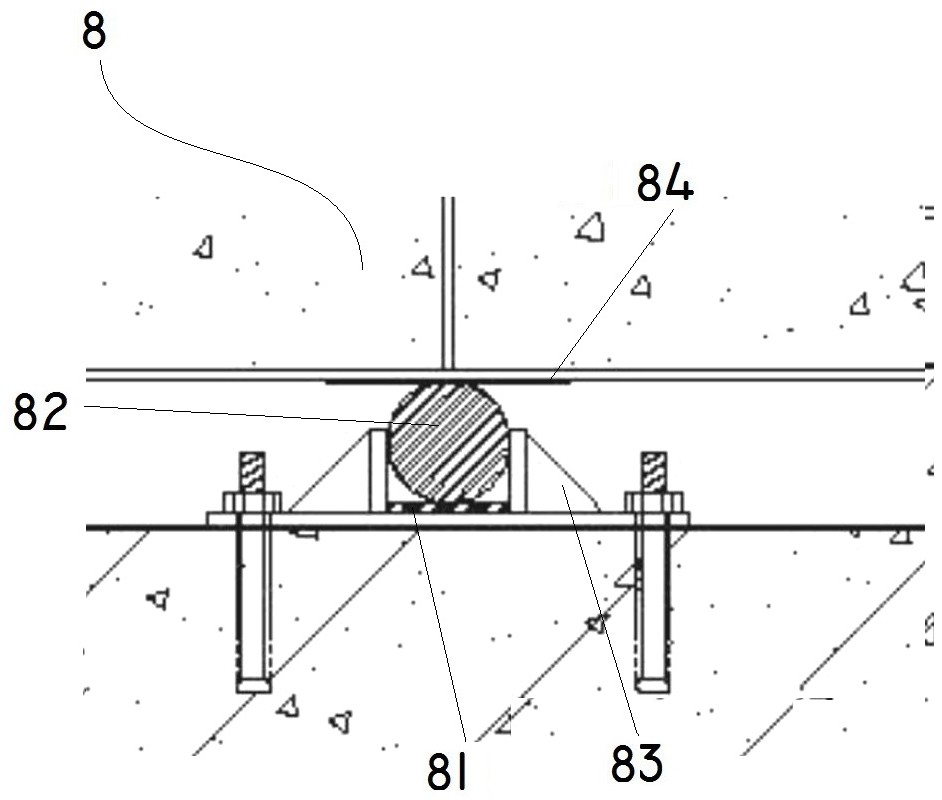

[0070] Such as figure 1 , 3 As shown in , 4, the shock-isolation deformation joint struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com