Fabricated steel bar connecting assembly and assembling method

A connecting component and prefabricated technology, applied in the processing of building components, building reinforcements, building materials, etc., can solve the problems of high processing precision of threaded joints, time-consuming and labor-intensive, etc., to achieve quality and strength assurance, simple and fast operation, easy to use processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

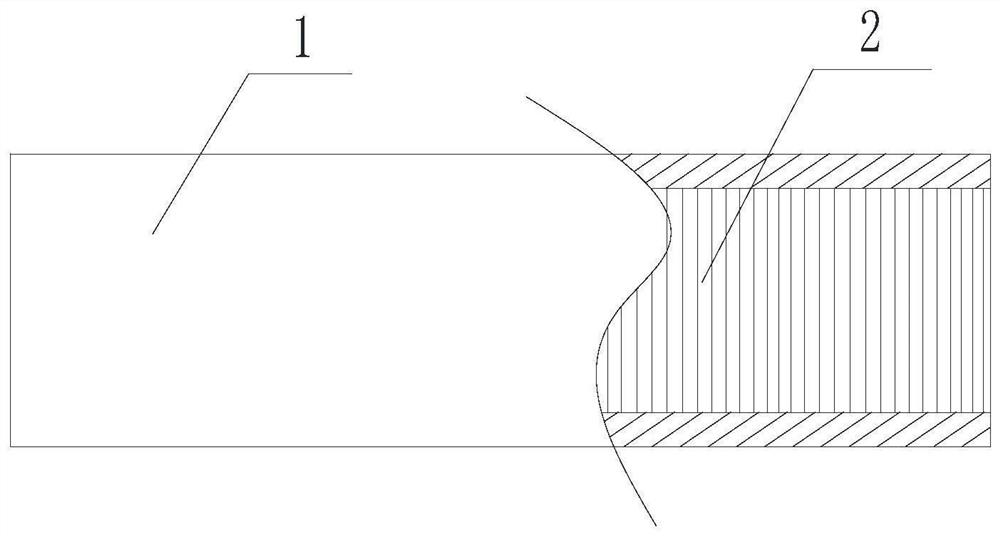

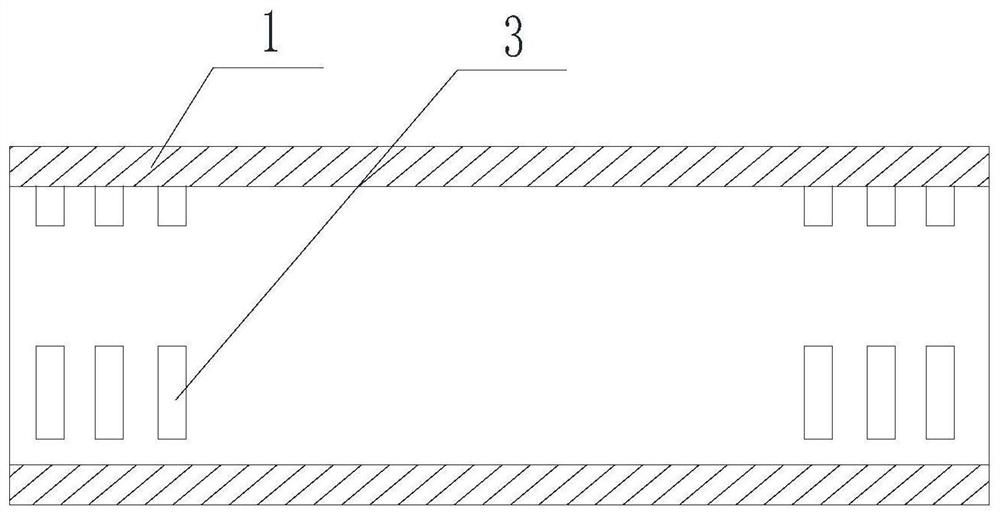

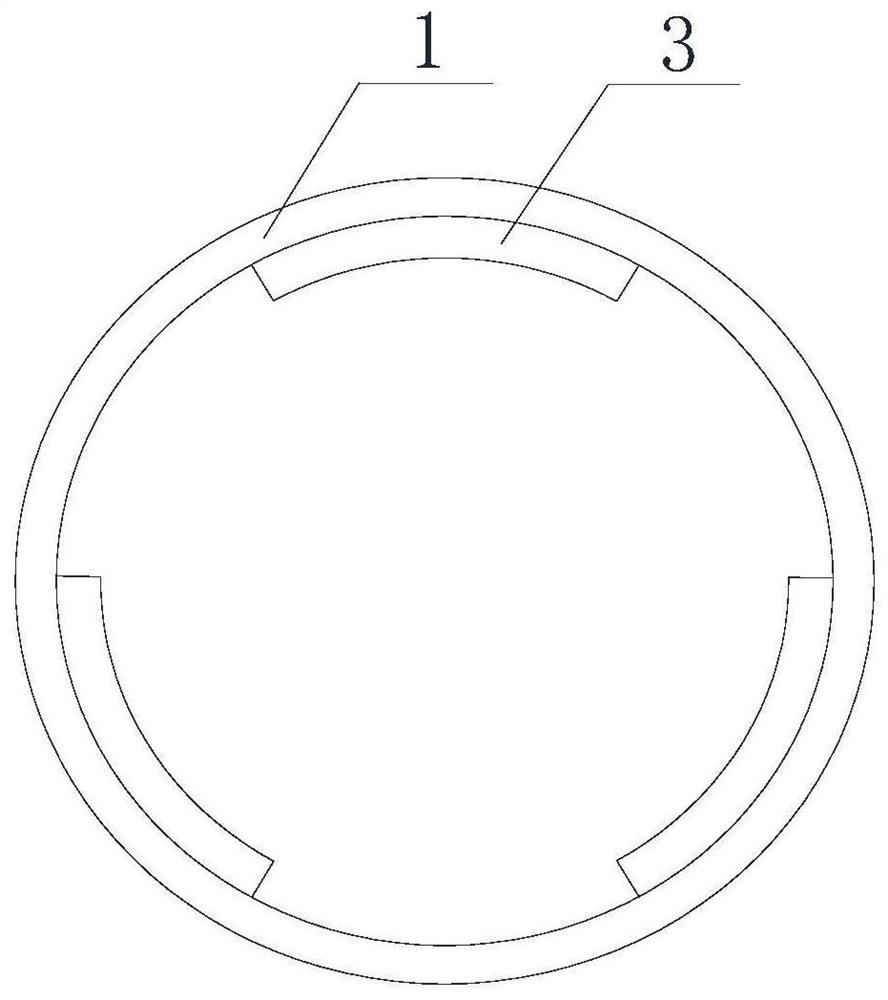

[0047] Such as Figure 2-Figure 9 As shown, the assembled steel bar connection assembly includes a sleeve 1 and a steel bar 5. Both ends of the inner wall of the sleeve 1 are provided with three first partition convex tooth structures in the axial direction. The first partition convex teeth The structure includes three first protruding teeth 3, and the three first protruding teeth 3 are arranged in an annular array on the inner wall of the sleeve 1, and the outer wall of one end of the steel bar 5 is provided with three second protruding teeth that cooperate with the first partition protruding tooth structure. The partition convex tooth structure, the second partition convex tooth structure includes 3 second convex teeth 6, and the 3 second convex teeth 6 are arranged in an annular array on the outer wall of one end of the steel bar 5, the first convex teeth 3 and The size and shape of the second protruding teeth 6 are the same, and the length of the second protruding teeth 6 ...

Embodiment 2

[0054] This embodiment is based on embodiment 1, and the difference of embodiment is:

[0055] Both ends of the inner wall of the sleeve 1 are provided with two first partition convex tooth structures, the first partition convex tooth structure includes four first convex teeth 3, and the end (joint) of the steel bar 5 is provided with Two second partition convex tooth structures, the second partition convex tooth structure includes four second convex teeth 6 .

Embodiment 3

[0057] This embodiment is based on embodiment 1, and the difference of embodiment is:

[0058] Both ends of the inner wall of the sleeve 1 are provided with four first partition convex tooth structures, the first partition convex tooth structure includes two first convex teeth 3, and the end (joint) of the steel bar 5 is provided with There are 4 second partition convex tooth structures, and the second partition convex tooth structure includes 2 second convex teeth 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com