Method for treating low oxygen of upper corner of stope face

A technology of mining working face and treatment method, which is applied in the direction of container discharge method, fluid treatment, container filling method, etc., which can solve the problems of complex process and high cost, inability to accurately cover, slow effect speed, etc., and achieve convenient operation and superior solution Corner hypoxia problem, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

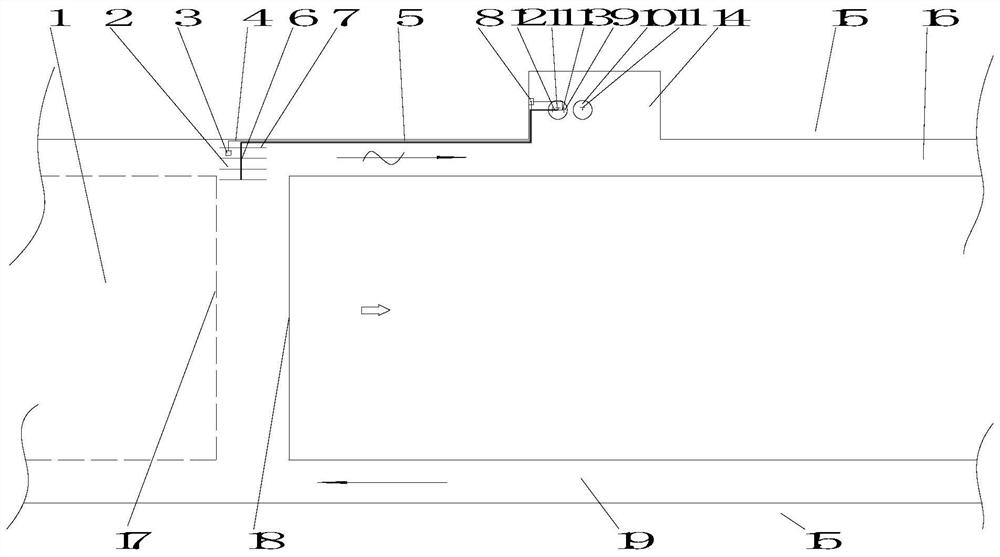

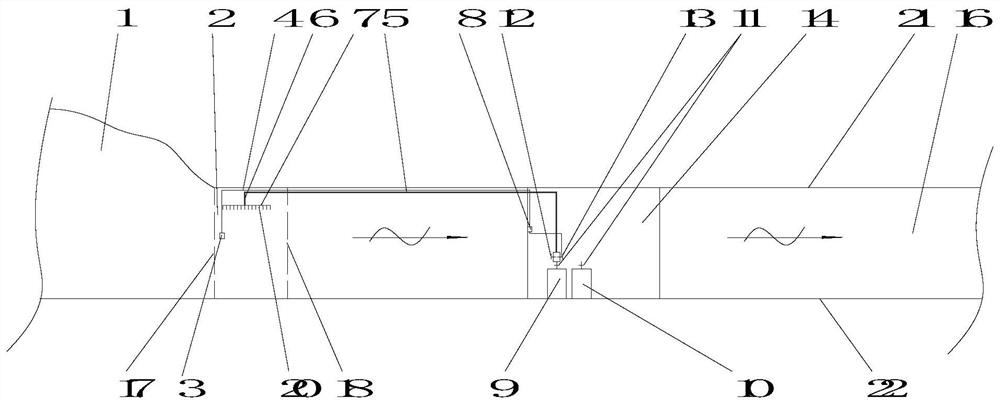

[0022] see figure 1 and figure 2 , a method for treating hypoxia in the upper corner of the mining face. On the upper corner 2 of the mining face 18, near the boundary 17 of the goaf, an explosion-proof oxygen concentration alarm 3 is suspended and installed, and the oxygen concentration alarm 3 The distance from the top plate 21 is 0.5m. The oxygen concentration alarm 3 has a built-in gas sensor and a single-chip program control unit, which can digitally display the oxygen concentration with LED, judge the state of the gas concentration and send alarm signals of different standards.

[0023] Oxygen concentration alarm 3 is connected with oxygen storage tank controller 8 by data line 4, and oxygen storage tank controller 8 is hung on the roadway chamber 14 near the upper corner 2 or the side wall at a suitable position. The height of the oxygen storage tank controller 8 from the bottom plate 22 is 1.4m, and is used to receive the oxygen concentration status signal sent by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com