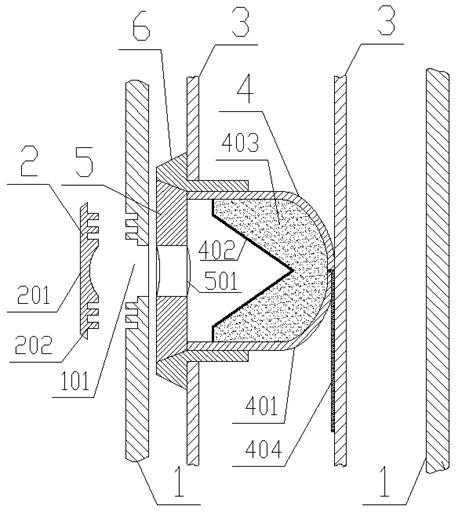

Overpressure combustion particle beam micro-channel fracture forming device

A particle beam and cracker technology, which is applied in the field of super-combustion particle beam micro-channel crackers, can solve the problems of efficient energy or concentrated work, performance discount, poor work intensification, etc., so as to improve oil production and improve permeability. , Improve the effect of opening degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

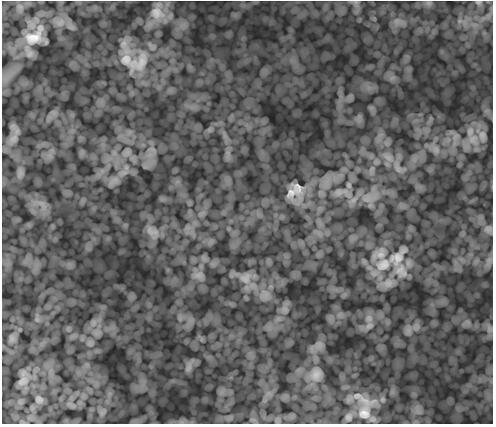

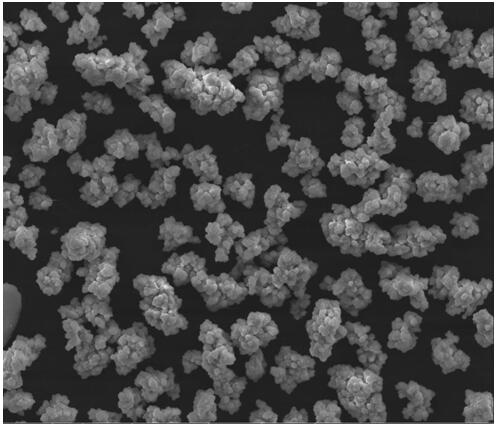

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Well T**32, well depth 2342m, oil layer thickness 6.5m, oil layer position: 3512.2 ~ 3518.5m, belongs to the low permeability block, has been producing steadily after putting into production, but before the measures were reformed, the reserves dropped sharply, so After the implementation of particle beam perforation fracturing technology, the blockage near the wellbore was unblocked, and the daily liquid production was 20t / d, and the daily oil production was 12t / d. Compared with the original production of 5t / d, the production increase effect is very significant.

Embodiment 2

[0036] Example 2: Well XJ**3, well depth 3319 m, oil layer thickness 10m, oil layer position: 2834--2843m. sandstone. The original daily liquid production was 8t / d, and the daily oil production was 3.6t / d. Fracturing was carried out using a super-combustible particle beam micro-channel fracturing device, and the construction operation went smoothly. After the operation, the fracker was lifted out of the well without any damage. Put into operation, the daily liquid production reaches 30t / d, and the daily oil production reaches 15t / d. The stimulation effect of fracturing is very good.

[0037] The invention improves the perforation effect by modifying the material and structure of the perforating bomb, thereby creating a good cracking channel space. Through the modification of the fracturing gun body, the constraint conditions when breaking holes are reduced, and powerful conditions are provided for the overpressure combustion of the supercombustible particle beam to do work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com