A negative electrode sheet and a lithium-ion battery including the negative electrode sheet

A negative electrode and lithium-ion technology, applied in the field of lithium-ion battery materials, can solve the problems of not being well compatible with high energy density and fast charging, and achieve fast charging and high energy density, energy density improvement, and fast charging Compatibility with high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1-1) Add 0.5wt% conductive carbon, 1.3wt% styrene-butadiene rubber, and 1.3wt% carboxymethyl cellulose to 96.9wt% fast-filling graphite, and then adjust with water to make negative electrode slurry A.

[0081] (1-2) Add 0.5wt% conductive carbon, 1.3wt% styrene-butadiene rubber, and 1.3wt% carboxymethyl cellulose to 96.9wt% conventional graphite, and then adjust with water to prepare negative electrode slurry B.

[0082] (1-3) The negative electrode slurry B is coated on the negative electrode current collector by double-layer coating equipment, the negative electrode slurry A is coated on the negative electrode slurry B, dried, rolled, cut, and sheeted, and prepared Negative plate.

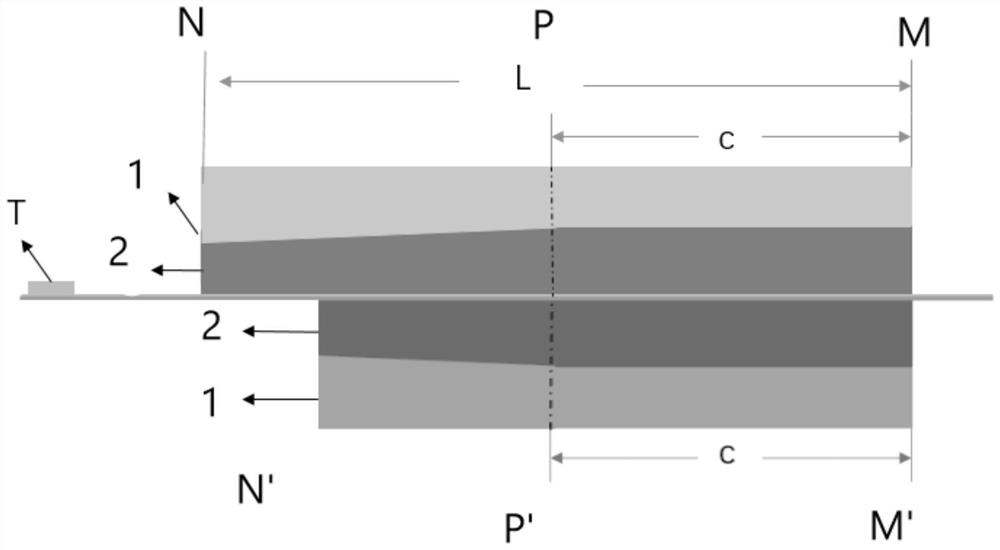

[0083] Specifically, the structure of the negative electrode sheet is as follows figure 1 As shown, from one end of the negative electrode current collector and along the length direction of the negative electrode current collector, the negative electrode current collector includes an emp...

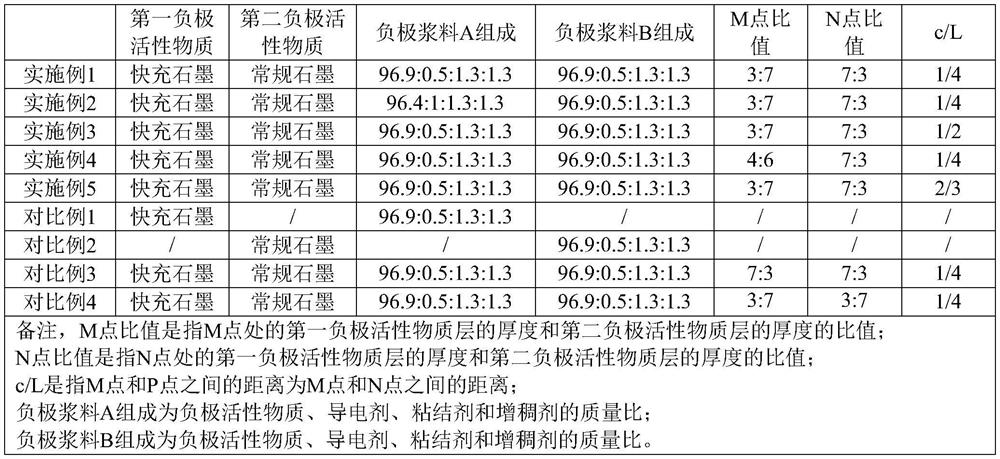

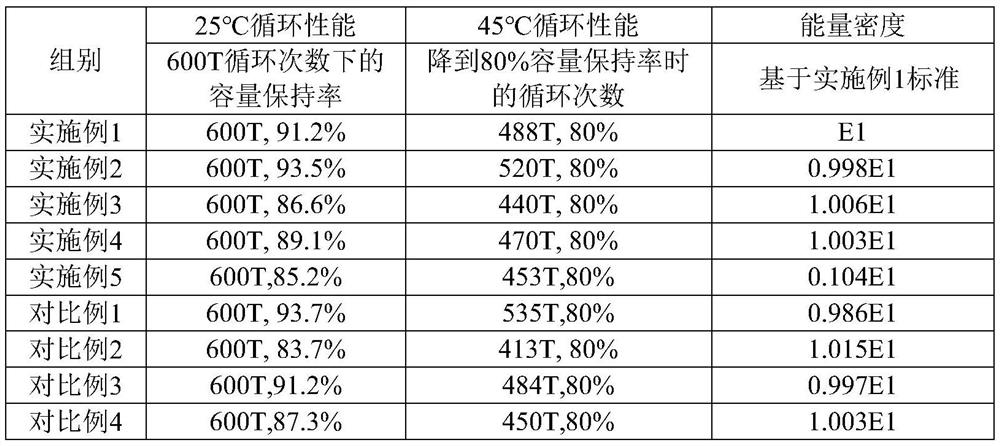

Embodiment 2-5

[0088] Examples 2-5 are the same as Example 1 except that the composition of the negative electrode slurry A and negative electrode slurry B is different, and the structure of the negative electrode sheet is different, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com