Recoil voltage protection device and method and multi-path servo motor drive control power supply system

A technology of recoil voltage and protection device, applied in the field of intelligent robots, can solve problems such as servo motor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

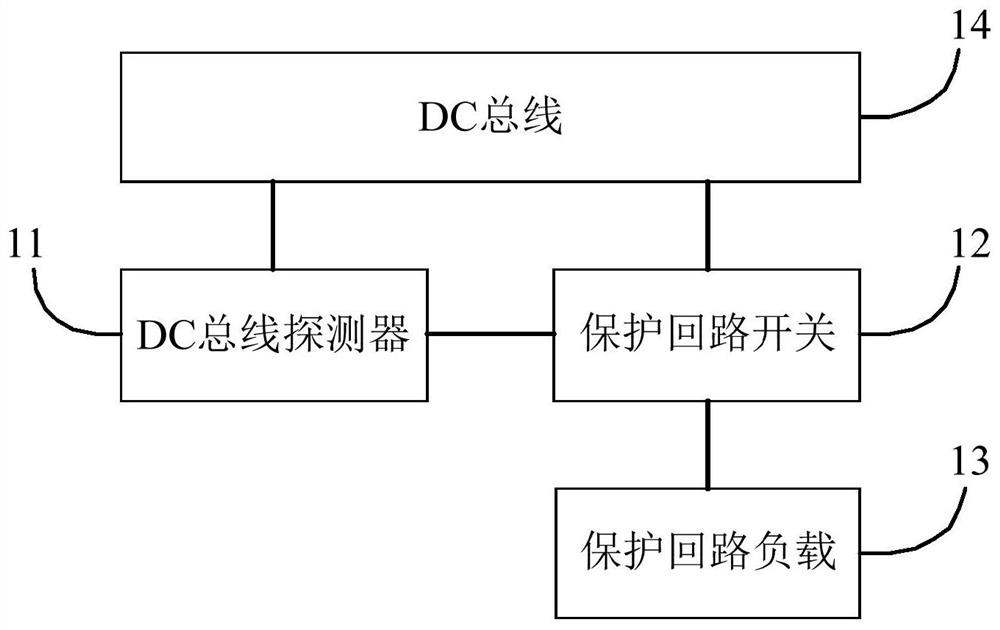

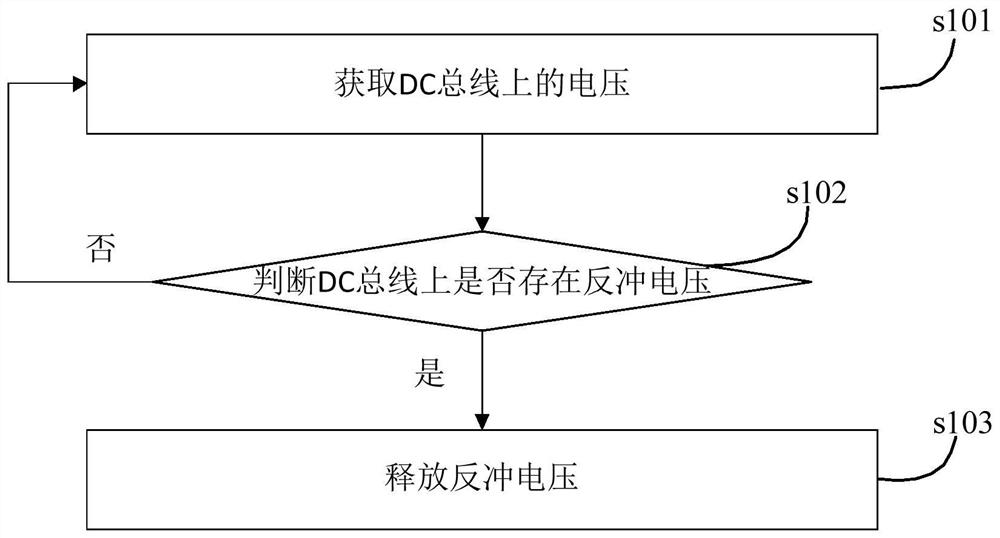

[0039] A kickback voltage protection device of this embodiment is as figure 1 As shown, the device includes a DC bus detector 11, a protection circuit switch 12 and a protection circuit load 13; the DC bus detector 11 is respectively connected to the DC bus 14 and the protection circuit switch 12 for detecting the DC The kickback voltage on the bus 14, and control the conduction and disconnection of the protective circuit switch 12 according to the detected kickback voltage; the protective circuit switch 12 is connected with the DC bus 14 and the protective circuit load 13 respectively, It is used to transfer the kickback voltage on the DC bus 14 to the protection circuit load 13 when it is turned on; the protection circuit load 13 is used to release the kickback voltage transmitted from the protection circuit switch 12 .

[0040] In this embodiment, the DC bus detector 11 includes a voltage detection unit and a voltage comparison unit; the voltage detection unit is used to de...

Embodiment 2

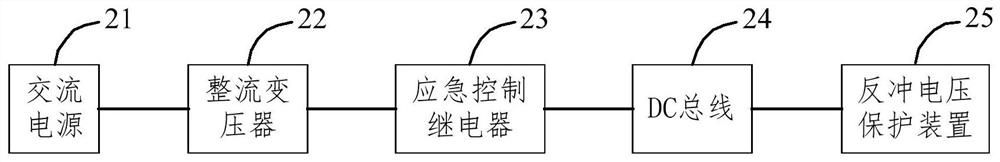

[0046] A multi-channel servo motor drive control power supply system in this embodiment is as follows: figure 2As shown, the system includes an AC power supply 21, a rectifier transformer 22, an emergency control relay 23, a DC bus 24 and a kickback voltage protection device 25; wherein, the input terminal of the rectifier transformer 22 is connected to the AC power supply 21, and the output terminal The input terminal of the emergency control relay 23 is connected, and the DC bus 24 is respectively connected with the output terminal of the emergency control relay 23 and the kickback voltage protection device 25 .

[0047] The rectifier transformer 22 is used to convert the AC power into a DC power supply, and the DC power supply is delivered to the DC bus 24 through the emergency control relay 23; the emergency control relay 23 is used to control the rectifier transformer The output end of 22 is connected and disconnected from the DC bus 24; the kickback voltage protection d...

Embodiment 3

[0051] This embodiment provides a multi-channel servo motor drive control power supply system, which is similar to the multi-channel servo motor drive control power supply system in embodiment 2. The difference from embodiment 2 is that this embodiment removes the emergency control relay and the rectifier transformer The input terminal is connected to the AC power supply, and the output terminal is directly connected to the DC bus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com