Elastic heat-conducting structure, manufacturing method thereof and electronic device

A technology of elastic heat conduction and electronic devices, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, electrical components, etc., and can solve problems such as increased weight and thickness, high density, and poor structural strength of polymer composite materials , to achieve the effect of good heat conduction and high heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

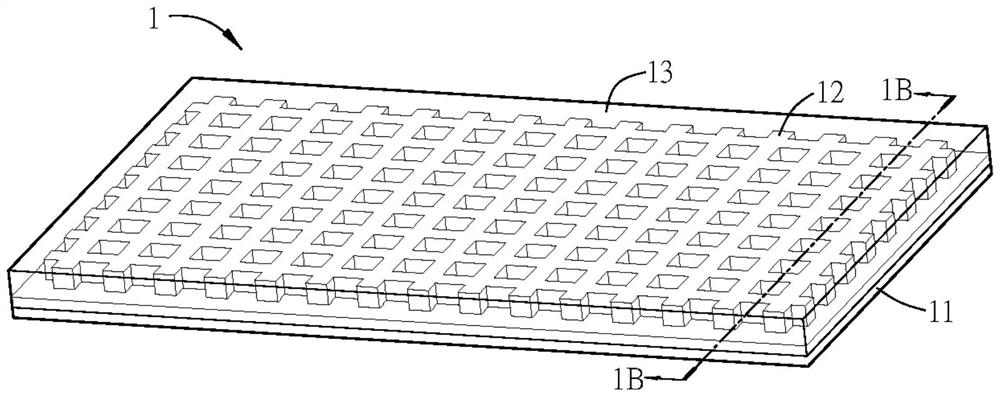

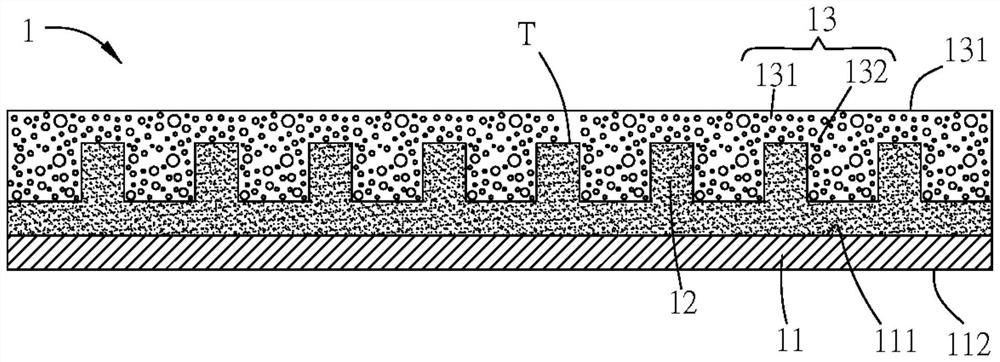

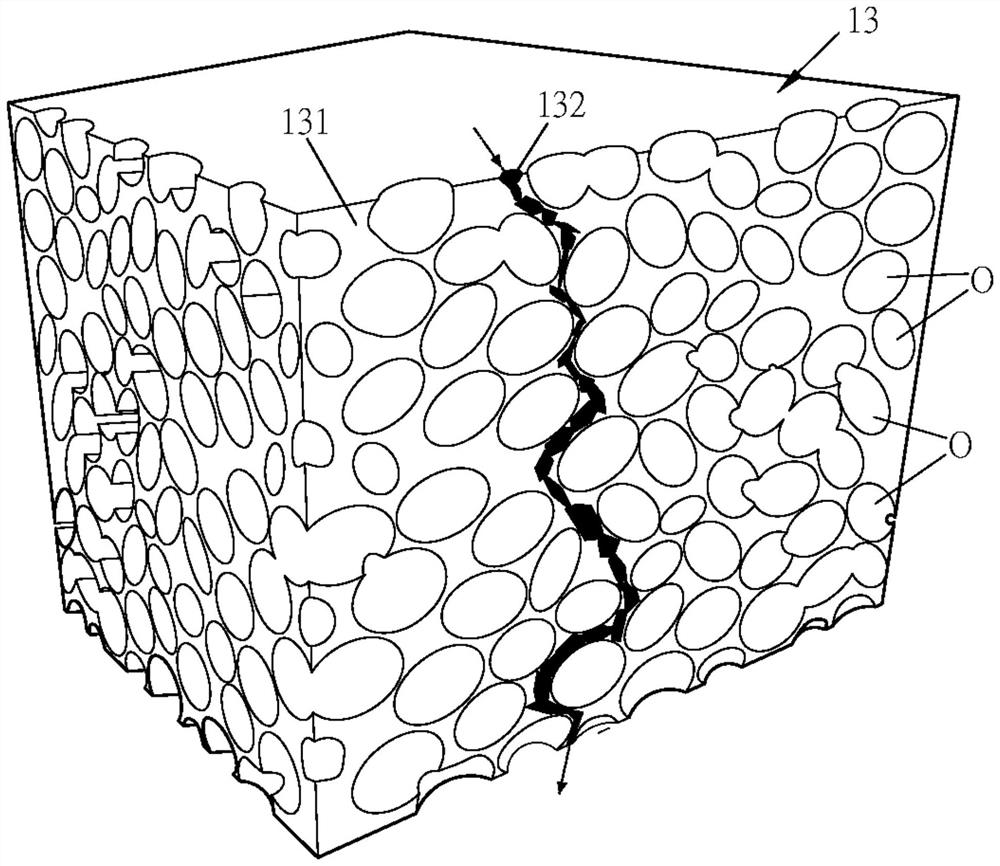

[0025] The elastic heat conduction structure and its manufacturing method, and the electronic device according to some embodiments of the present invention will be described below with reference to the relevant drawings, wherein the same components will be described with the same reference symbols. Components appearing in the following embodiments are only schematic and do not represent real scales or dimensions.

[0026] The elastic heat conduction structure of the present application can be applied to, for example but not limited to, mobile phones, notebook computers, tablet computers, televisions, monitors, backlight modules, or computer equipment related to servers, or unmanned aerial vehicles, audio-visual equipment (such as speakers), photography lenses Or camera lenses, or electronic devices in other fields, are not limited. The elastic heat conduction structure of the present application can not only achieve higher heat conduction and heat extraction efficiency through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com