Water expansion type cleaning equipment for sausage casing production and processing

A technology for cleaning equipment and water swelling, which is applied in the direction of cleaning intestines and adapting to climate change. It can solve the problems of unrecyclable water resources, residual impurities in the interior, and limited effect, so as to improve the recycling rate of resources and facilitate the discharge of materials. cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

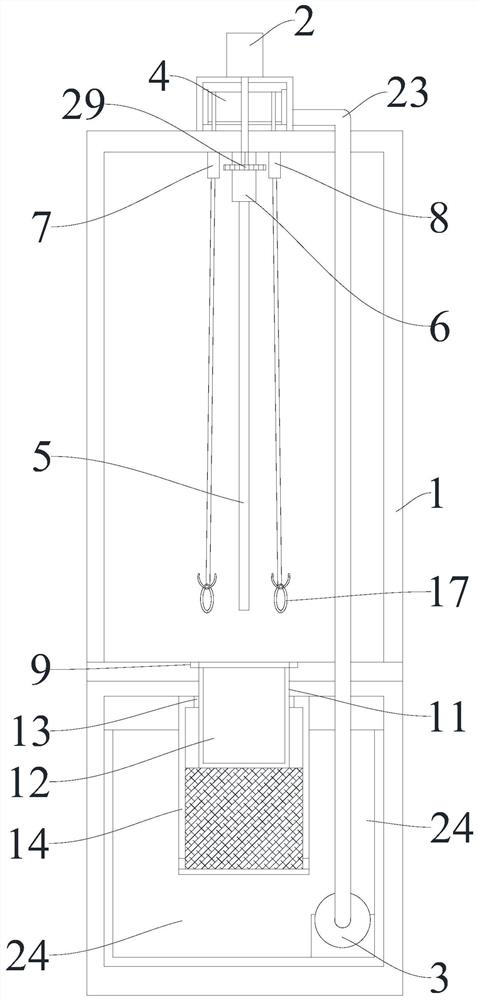

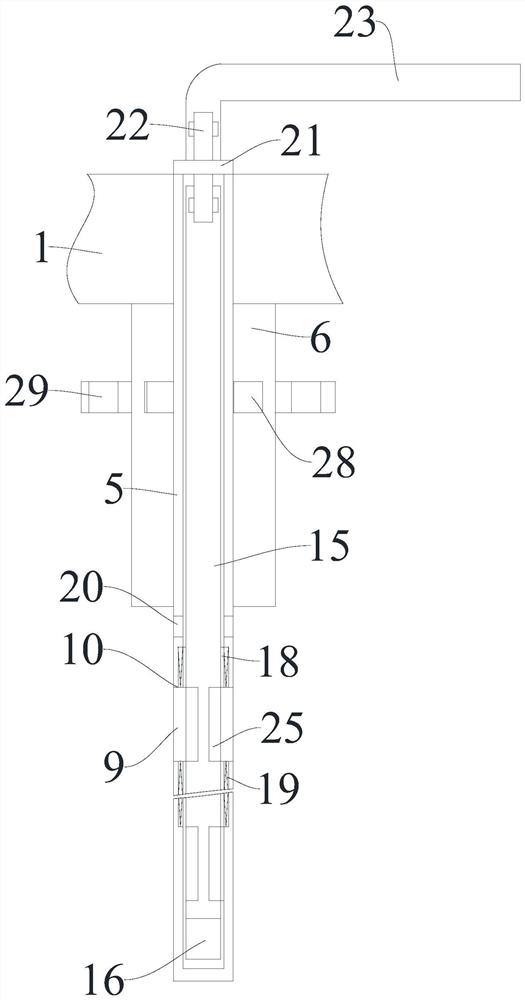

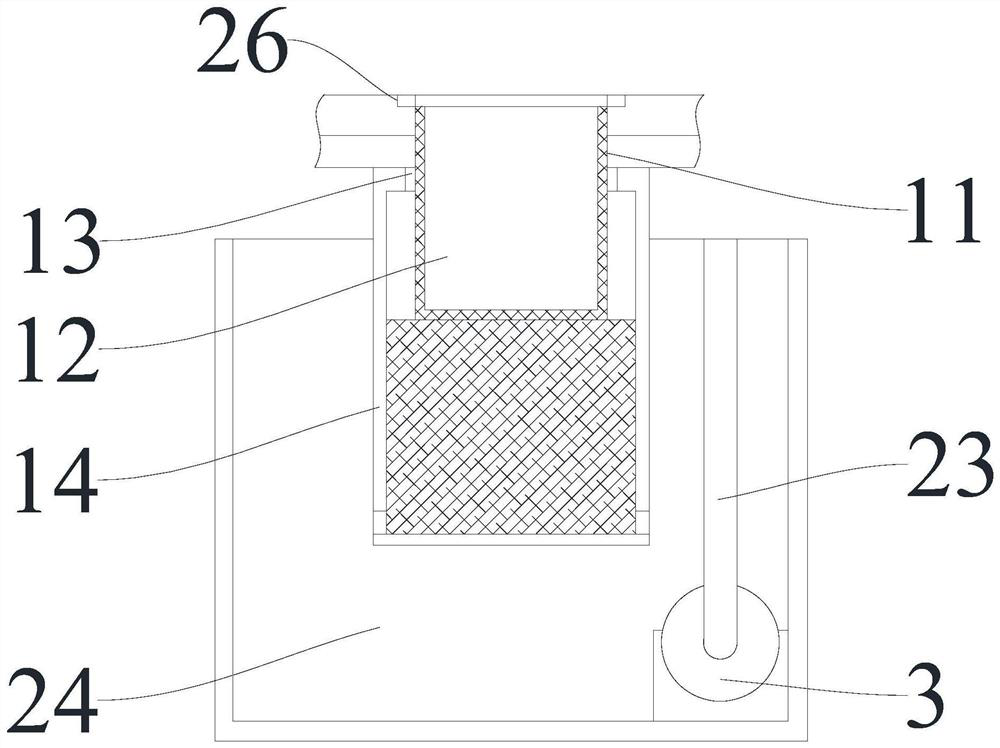

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] figure 1 , figure 2 and image 3 The shown casing production and processing water expansion type cleaning equipment includes a main frame 1, an overhead motor 2 installed on the main frame 1, a small booster water pump 3 and a small winch machine 4, an overhead motor 2, a small booster The water pump 3 and the small winch 4 are directly purchased from the market, powered by an external power supply, and controlled by an external switch to open and close and forward and reverse. The main frame 1 is provided with a longitudinal transmission pipe 5, and the inner top surface of the main frame 1 is welded and fixed. The top guide installation pipe 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com