Dump leaching remediation system for chromium contaminated soil

A chromium-contaminated soil and repair system technology, applied in the restoration of contaminated soil, etc., can solve the problems of long infrastructure construction period, structures need to be demolished, time-consuming, labor-intensive and cost-intensive, etc., to facilitate popularization and use, improve restoration efficiency, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

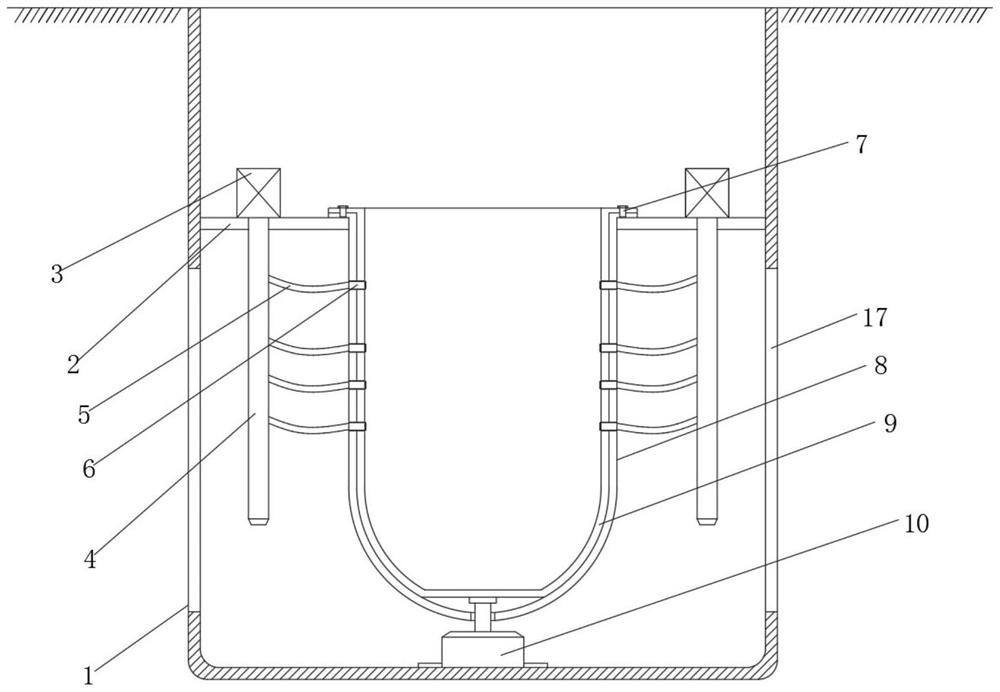

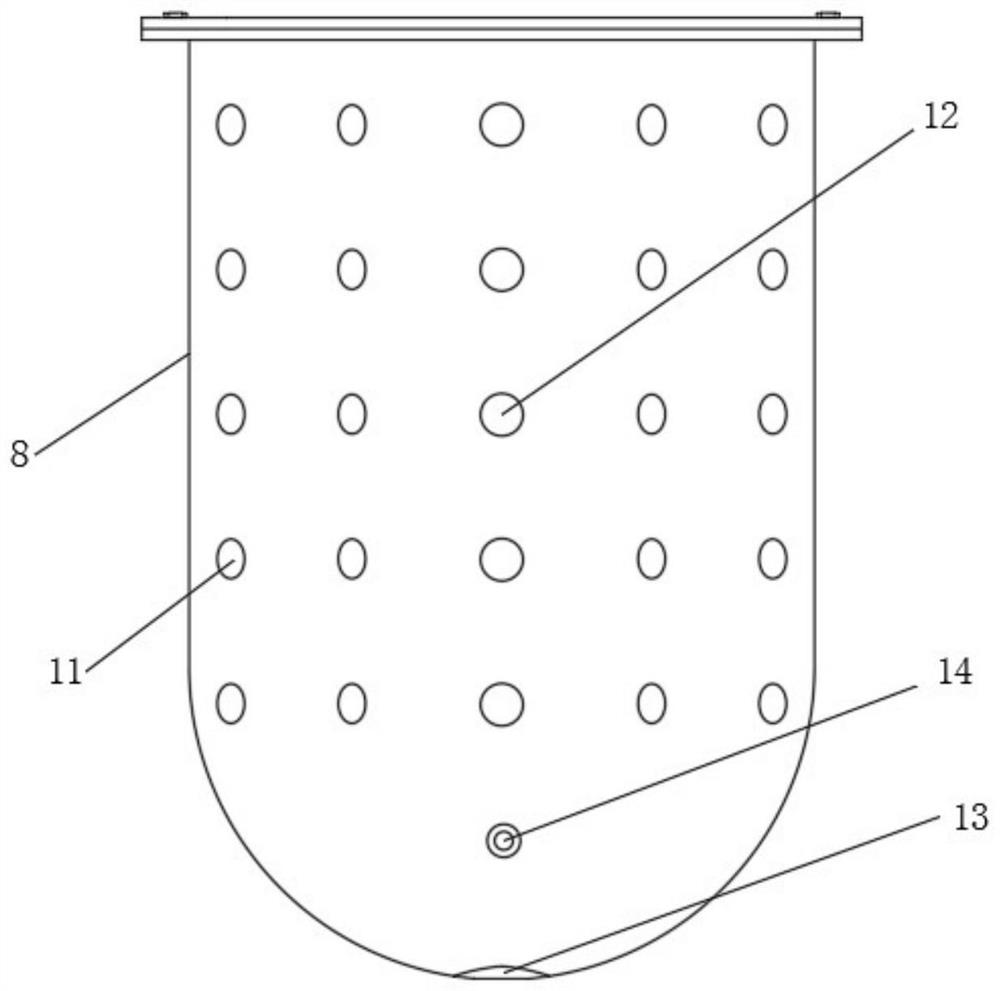

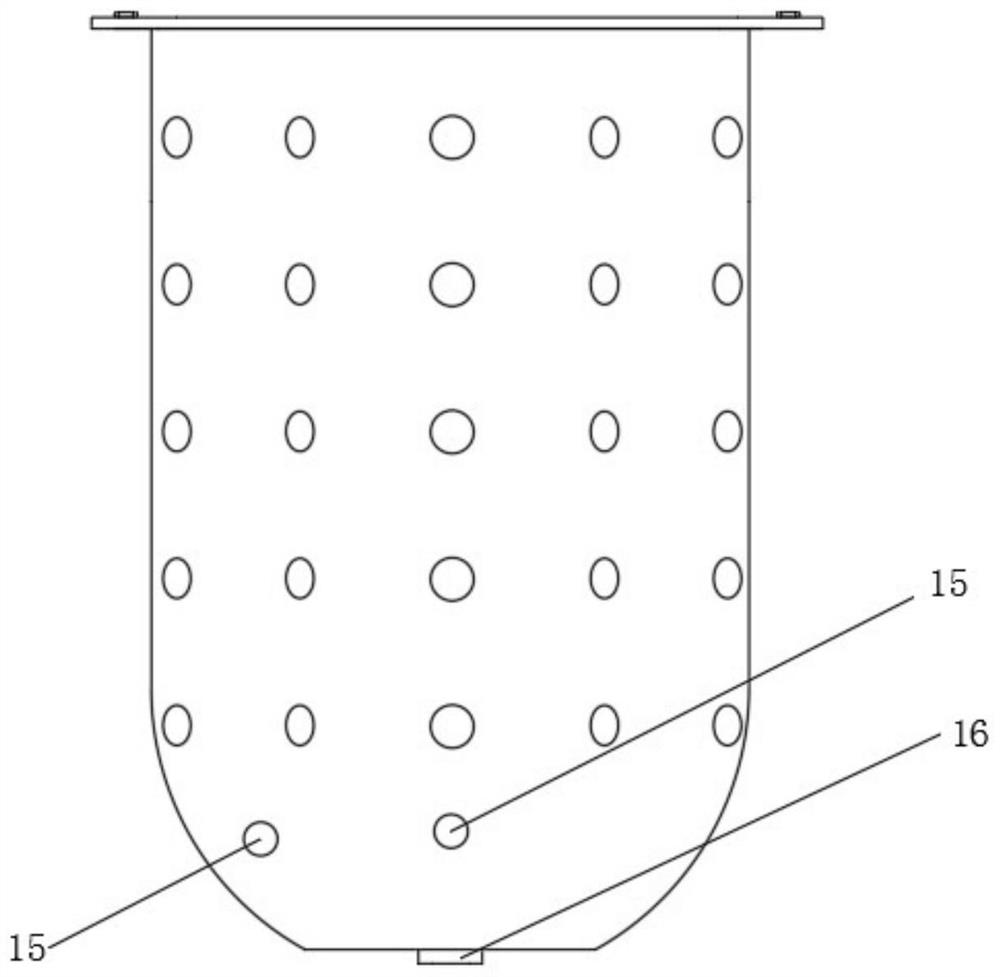

[0021] Such as Figure 1-4 As shown, a heap leaching restoration system for chromium-contaminated soil includes a buried shell 1, which is buried below the ground, and a storage part is placed inside the buried shell 1, and chromium pollution is stored in the storage part. soil heap, the inside of the buried shell 1 is also filled with repair soil, the outer surface of the storage part is connected with a spray pipe, and the spray pipe sprays the repair liquid into the storage part, and the buried shell 1 The outer surface is provided with a circulation port 17.

[0022] The inside of the buried shell 1 is fixedly connected with a built-in support plate 2, and the built-in support plate 2 is provided with a placement opening, the storage part is placed in the placement opening, and the circulation opening 17 is opened at the lower position of the built-in support plate 2; The spray pipe part includes a liquid inlet valve part 3. When in use, the repair liquid can be externall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com