Intelligent control system and method for electric furnace charging crane

An intelligent control system and crane technology, applied in furnaces, furnace components, charge control, etc., can solve the problems of complex production environment of electric furnace plants, inability to carry out unmanned promotion, and harsh high temperature resistance performance of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

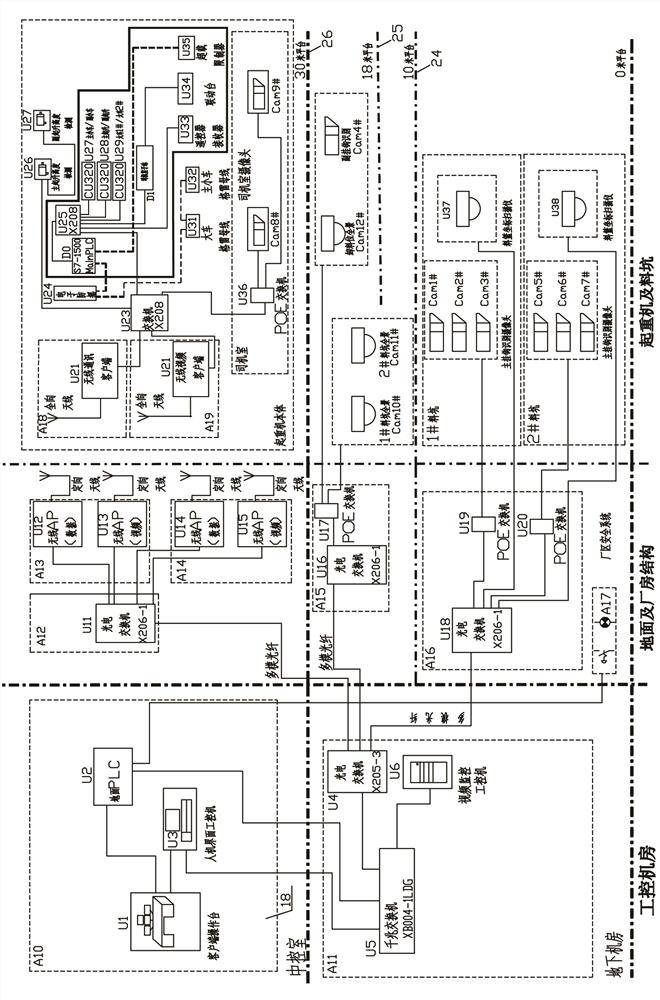

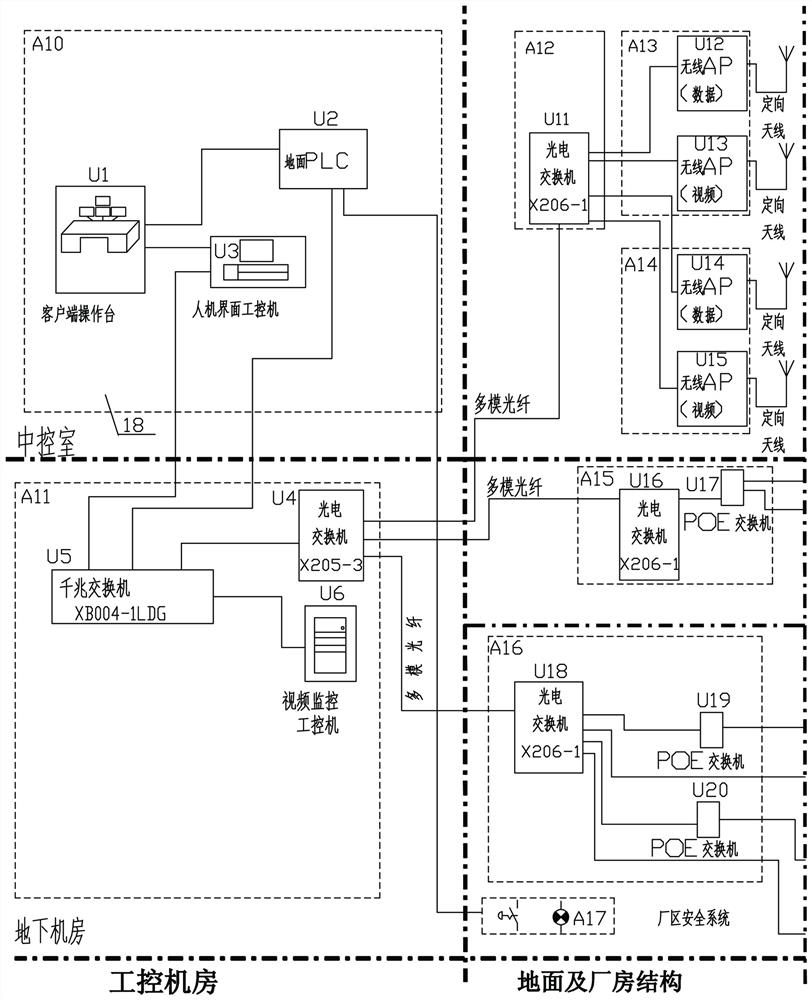

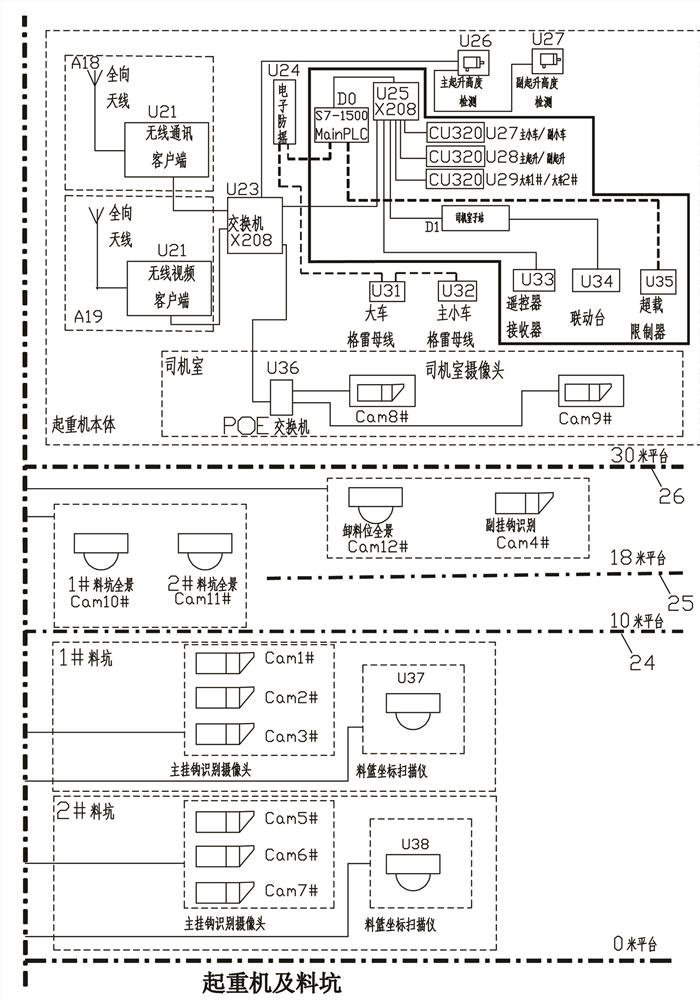

[0084] The present invention aims at solving several technical difficulties of the intelligent operation of the electric furnace feeding crane respectively, and solves several technical difficulties of the electric furnace feeding crane to realize the intelligent operation through hardware means supplemented by software means, so as to realize the intelligent operation of the electric furnace feeding crane control.

[0085] The main task of the electric furnace feeding crane is to charge the electric furnace. During the feeding task, the material basket in the material pit is hoisted to the top of the electric furnace, and then through the cooperation of the main lifting mechanism and the auxiliary lifting mechanism, the discharge door at the bottom of the material basket is opened, and then the scrap steel (or Other raw materials) can automatically fall into the electric furnace due to gravity, so as to complete the feeding task. After the feeding is completed, close the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com