A stacking device for the processing and production of flywheel shells

A flywheel housing and top-mounted technology, which is applied in transportation and packaging, load hanging components, cranes, etc., can solve the problems of high cost of cranes, limited use position, low stacking efficiency, etc., to achieve diverse use environments, improved processing efficiency, Enhanced durability and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

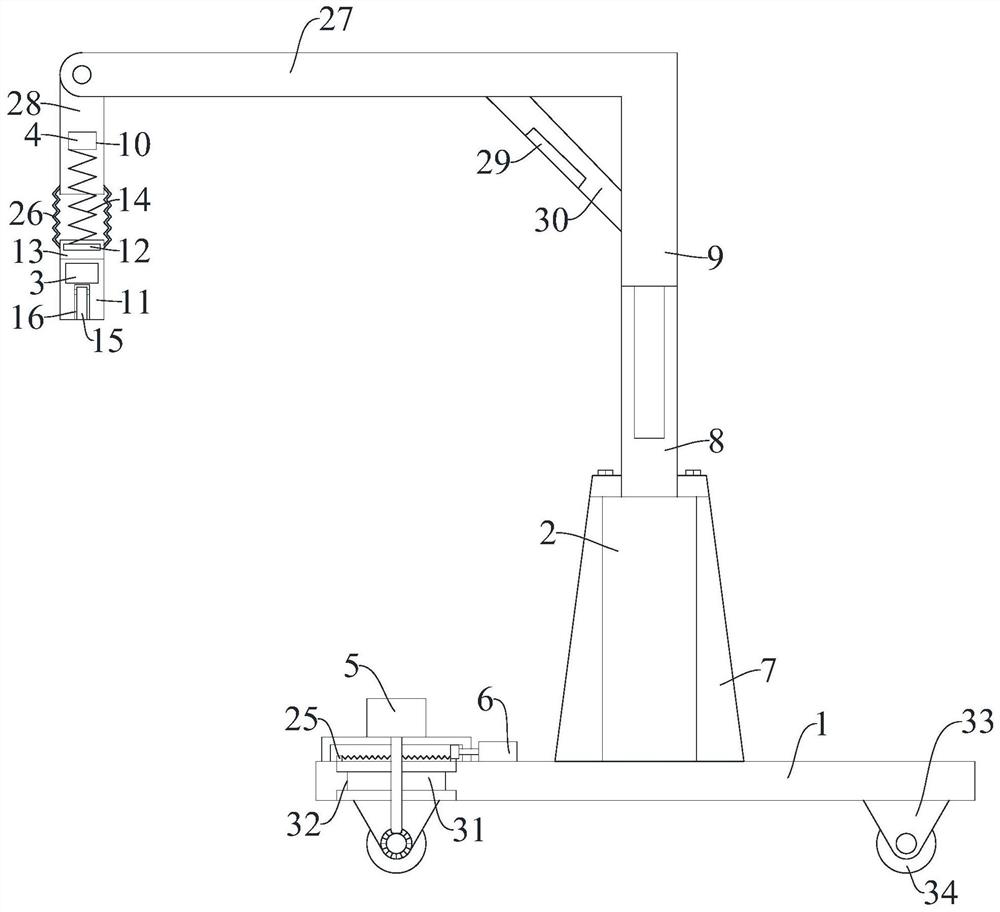

[0025] Embodiment: Electric control hydraulic elevator 2, driving motor 3, ring electromagnet 4, upper adjustment motor 5 and side adjustment motor 6 are purchased directly through the market, and through the control switch panel 29 on the side control handle 30, respectively Take control of it.

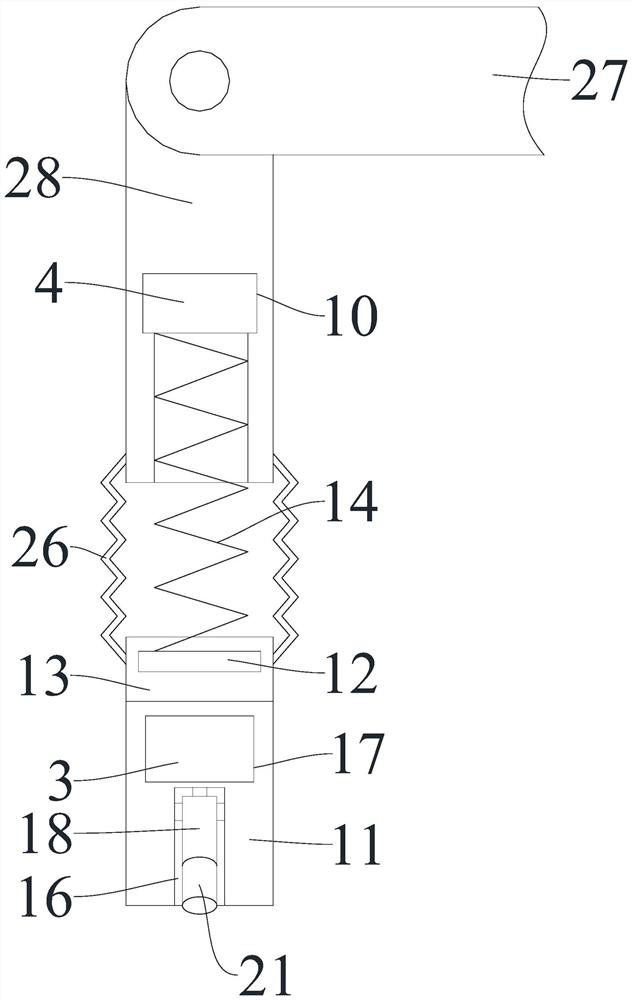

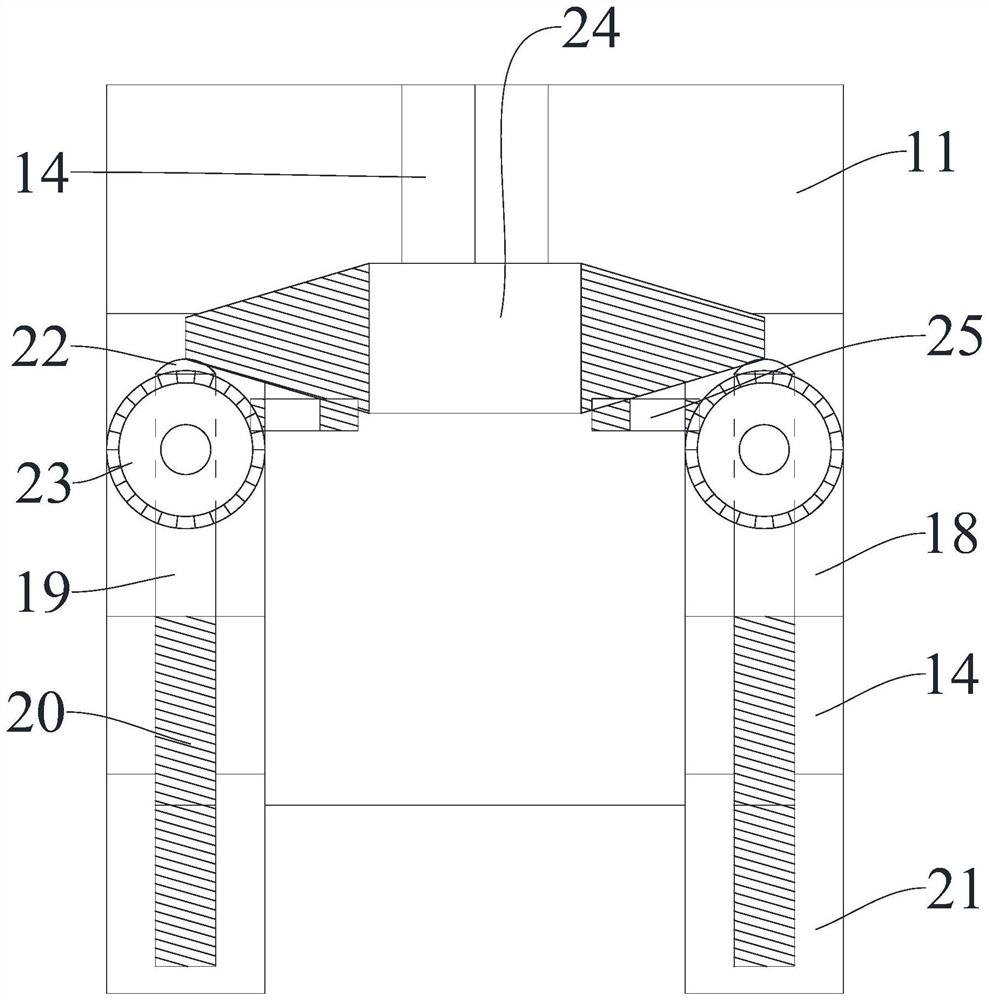

[0026] The drive motor 3 rotates to drive the spherical transmission gear 22 and the lateral linkage gear 25 to rotate, the spherical transmission gear 22 drives the internal adjustment rod 19 to rotate, and the lateral linkage gear 25 drives the lateral gear plate 23 to rotate, thereby driving the internal turning cylinder 18 and The externally telescopic internally threaded pipe 21 is turned outward, so as to achieve the purpose of stretching while turning over.

[0027] Further, in order to control the sideways turning and stretching, the turning limit lever 15 includes an inner turning cylinder 18 which is movably installed inside the sideways turning storage tank 16 through a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com