A kind of high damping high strength mg-ca-sn magnesium alloy and its preparation method

A mg-ca-sn, magnesium alloy technology, applied in the field of high damping alloy materials and its preparation, can solve the problems of unbalanced mechanical properties and damping properties of binary magnesium alloys, failure to meet industrial requirements, complex production process, etc., to achieve Improve the effect of dislocation damping, avoid plugging and winding, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

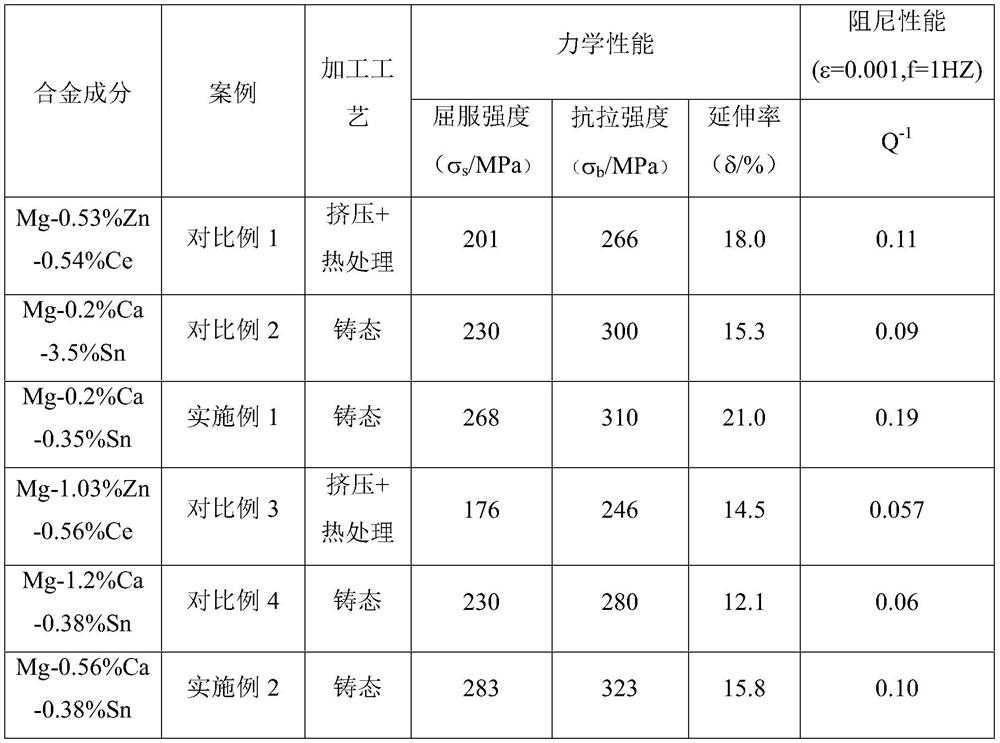

Examples

Embodiment 1

[0033] The selected alloy is Mg-Ca-Sn series magnesium alloy. According to the mass percentage, the Ca content is 0.2%, the Sn content is 0.35%, and the balance is Mg and unavoidable impurities, and the impurity content is ≤0.05%.

[0034] The preparation of the alloy is carried out according to the following steps:

[0035] (1) carrying out batching according to the mass percentage of described magnesium alloy;

[0036] (2) Place commercially pure magnesium, Mg-20% Ca master alloy and Mg-20% Sn master alloy in an oven for preheating at 200°C for 2 hours to eliminate moisture in the raw materials;

[0037] (3) CO at a volume ratio of 100:1 2 and SF 6 Under the protection of protective gas, the preheated industrial pure magnesium is heated to 700°C for melting;

[0038] (4) Raising the temperature of the pure magnesium melt to 740° C., removing scum on the surface of the melt, adding Mg-20% Sn master alloy and Mg-20% Ca master alloy to the pure magnesium melt, until the abov...

Embodiment 2

[0041] The selected alloy is Mg-Ca-Sn series magnesium alloy. According to the mass percentage, the Ca content is 0.56%, the Sn content is 0.38%, and the balance is Mg and unavoidable impurities, and the impurity content is ≤0.05%.

[0042] The preparation of the alloy is carried out according to the following steps:

[0043] (1) carrying out batching according to the mass percentage of described magnesium alloy;

[0044] (2) Place commercially pure magnesium, Mg-20% Ca master alloy and Mg-20% Sn master alloy in an oven for preheating at 200°C for 2 hours to eliminate moisture in the raw materials;

[0045] (3) CO at a volume ratio of 100:1 2 and SF 6 Under the protection of protective gas, the preheated industrial pure magnesium is heated to 700°C for melting;

[0046] (4) Raising the temperature of the pure magnesium melt to 740° C., removing scum on the surface of the melt, adding Mg-20% Sn master alloy and Mg-20% Ca master alloy to the pure magnesium melt, until the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com