Combined yarn carrier guiding device of knitting machine

A guiding device and combined technology, applied in the direction of woven fabrics, textiles and papermaking, can solve the problems of low manufacturing yield, long processing cycle, difficult to replace, etc., and achieve the effect of high yield, short processing cycle and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

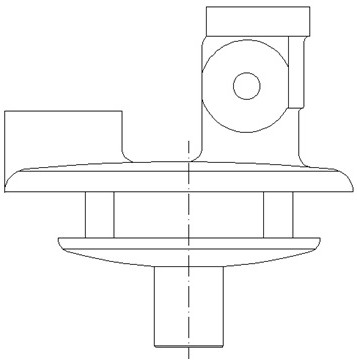

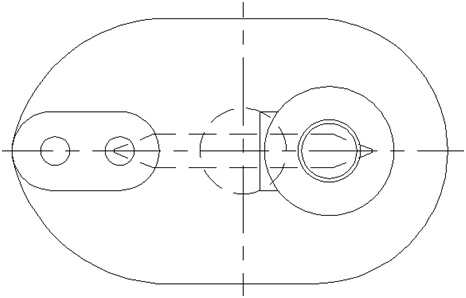

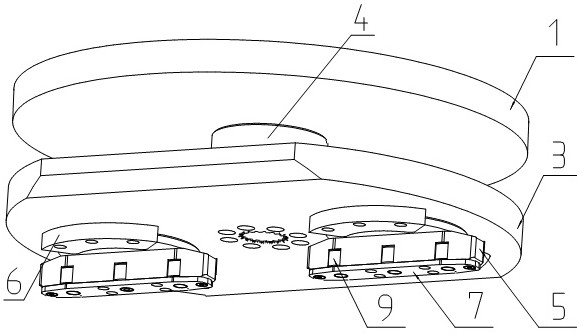

[0027] Embodiment 1: The combined yarn carrier guiding device of the knitting machine of the present invention includes: an upper plate 1, a mandrel 2, a lower plate 3, a rotating sleeve 4, a guide block 5, a guide block supporting plate 6, a guide block bottom plate 7, Roller shaft 8 and roller 9;

[0028] An upper plate 1 and a lower plate 3 are connected to both ends of the mandrel 2, and a rotating sleeve 4 that can rotate freely is sleeved on the mandrel 2 between the upper plate 1 and the lower plate 3; In the hole, there is a guide block 5 that can rotate freely, and the guide block 5 is supported on the lower plate 3 by the guide block supporting plate 6 to prevent the guide block 5 from falling from the lower plate 3; a roller shaft 8 is installed in the guide block 5 , on the roller shaft 8 there are rollers 9 that can rotate freely;

[0029] The center of the upper plate 1 and the lower plate 3 has a mandrel hole, and screw fixing holes uniformly distributed along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com