Steel supporting cone-wedge expanded movable end device for collaborative construction of foundation pit groups and construction method thereof

A technology of steel support and foundation pit group, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of central partition wall load concentration, poor integrity, unreliability, etc., to reduce load concentration and unbalanced, unbalanced distribution. The effect of improvement and reliability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

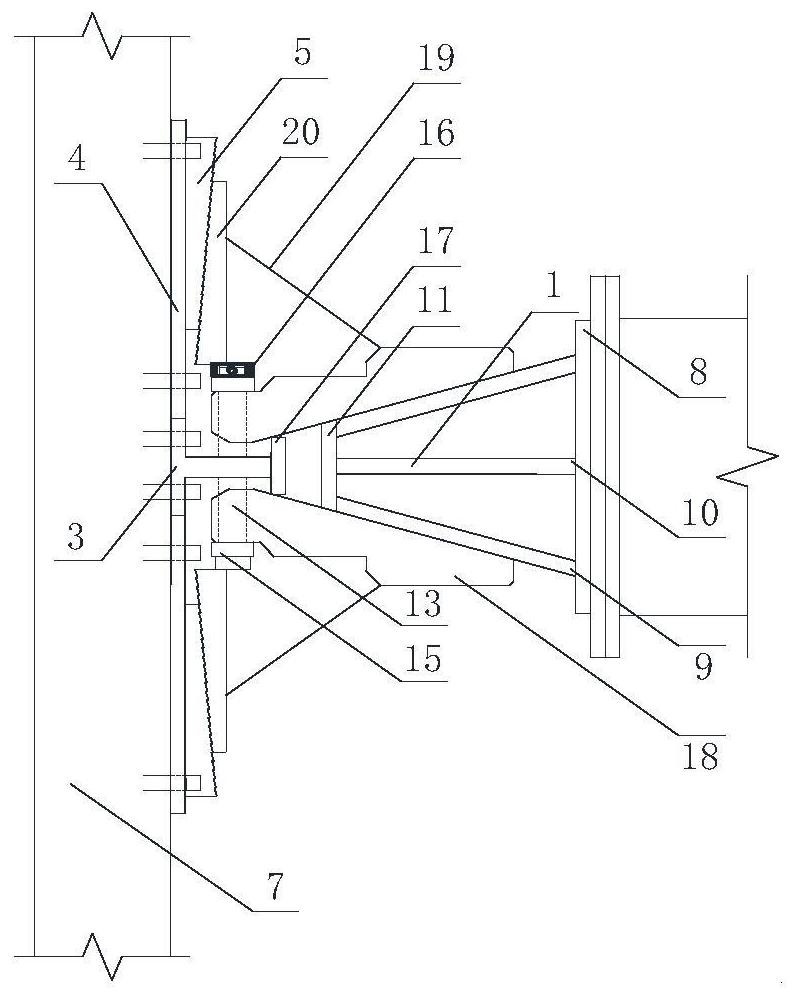

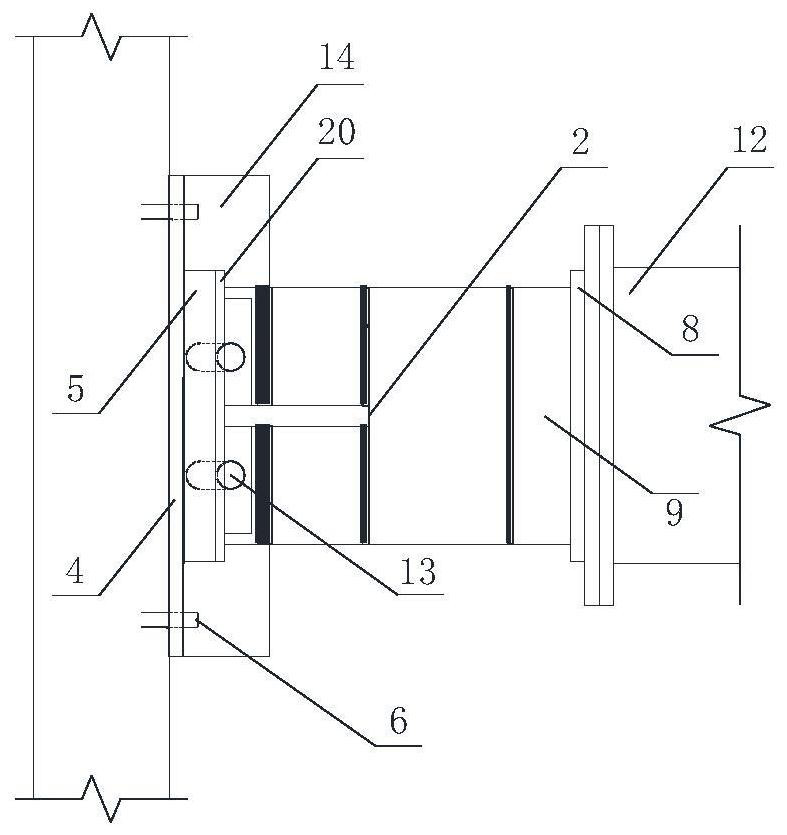

[0019] Attached below figure 1 The technical scheme of the present invention is described in detail:

[0020] A steel-supported cone-wedge extended-type active joint device for coordinated construction of foundation pit groups according to the present invention includes a cone-wedge-shaped support 1 with a flange, an inclined splint 2 with a flange, and a stopper 3 with a jack mounting plate , Stress diffusion bearing plate 4, fixed position plug plate 5, fixed anchor rod 6, ring beam or purlin 7, flange 8, tapered wedge-shaped inclined plate 9, reinforcement plate 10, jack contact plate 11, steel support steel pipe section 12 , Smooth round rod 13, center limiter 14, smooth round rod mount 15, end limiter 16, jack mounting plate 17, inclined splint 18, flange 19, flange supporting plate 20.

[0021] Among them, the center point of the limiter 3 with the jack mounting plate is aligned with the center point of the cone-wedge-shaped support 1 with a flange, so that the load-bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com