Vertical oil-gas separator for separating petroleum

A technology for oil and gas separators and oil, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc. It can solve the problems of low buffer efficiency, poor oil fluidity, hinder the operation of buffer baffles, etc., and achieve high discharge efficiency. , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

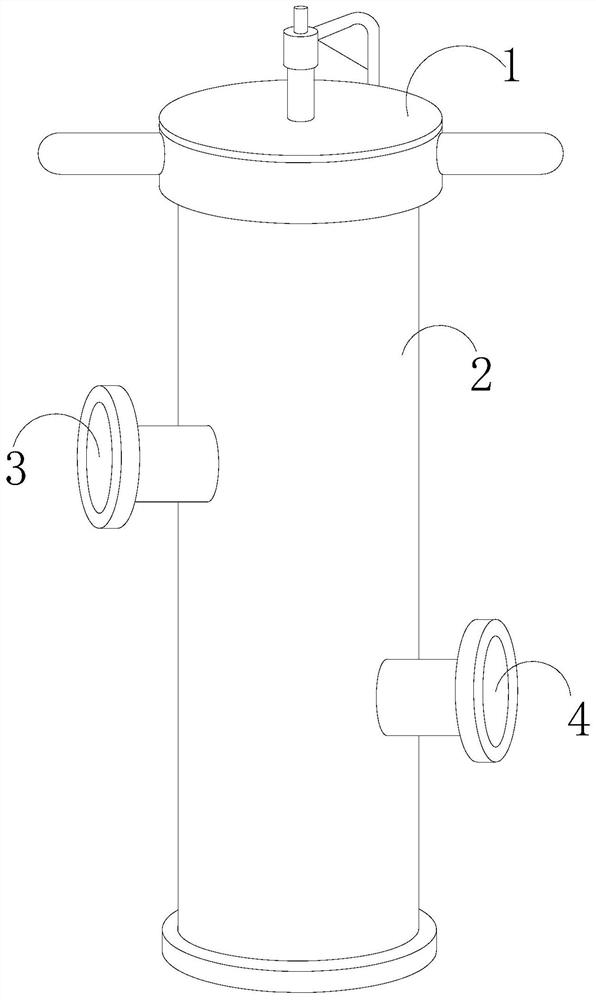

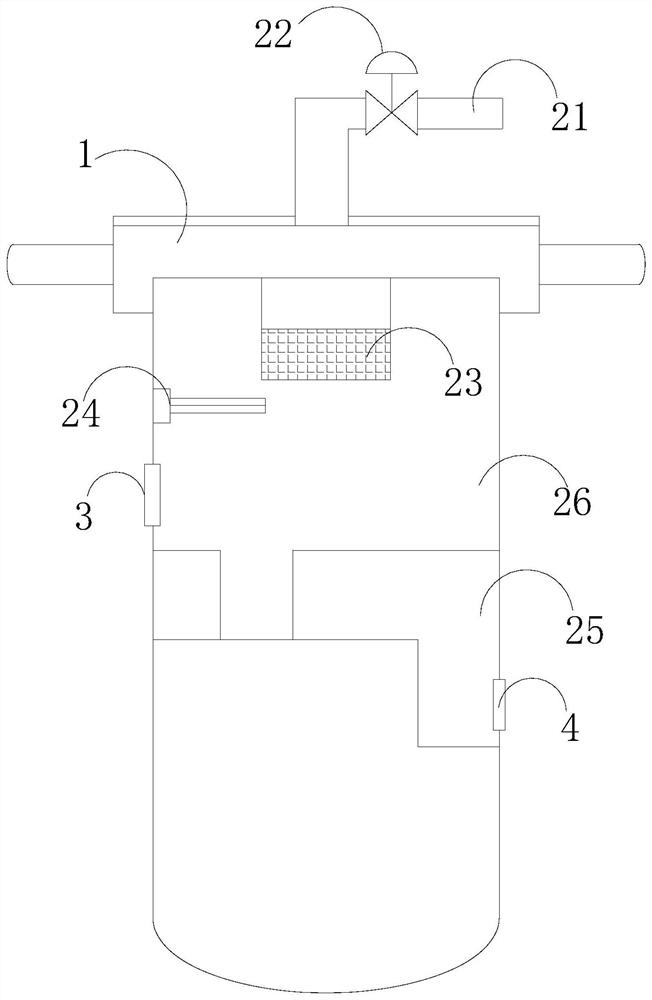

[0024] Such as Figure 1-Figure 6 As shown, the present invention provides a vertical oil-gas separator, the structure of which includes a sealing end cover 1, a body 2, an inlet 3, and an oil outlet 4, and the upper end of the body 2 is equipped with a sealing end cover 1 , the left side of the body 2 is provided with an inlet 3, and the right side is provided with an oil outlet 4, and the body 2 is provided with a gas outlet 21, a pressure control valve 22, a mist catcher 23, a buffer plate 24, An oil collection tank 25 and a separation chamber 26, the gas outlet 21 is equipped with a pressure control valve 22, the interior of the separation chamber 26 is provided with a mist catcher 23, a buffer plate 24, and an oil collection tank 25, and the buffer plate 24 is located at the inlet 3, the oil collecting groove 25 cooperates with the oil outlet 4.

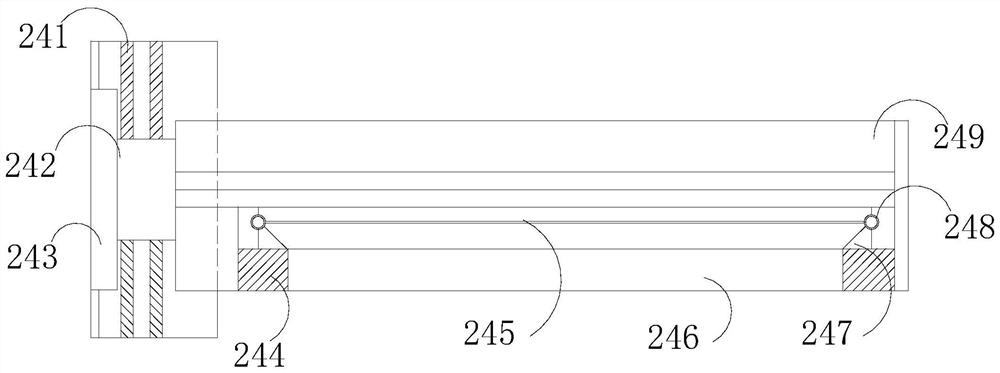

[0025] The buffer plate 24 includes a buffer spring 241, a buffer slider 242, a connecting slideway 243, a liquid squeezer 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com