Thermal weight loss automatic detection device and system

An automatic detection and thermal weight loss technology, applied in chemical instruments and methods, crucibles, laboratory utensils, etc., can solve the problems of repeatability of results, measurement error, volume increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The thermogravimetric automatic detection device and system involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0062]

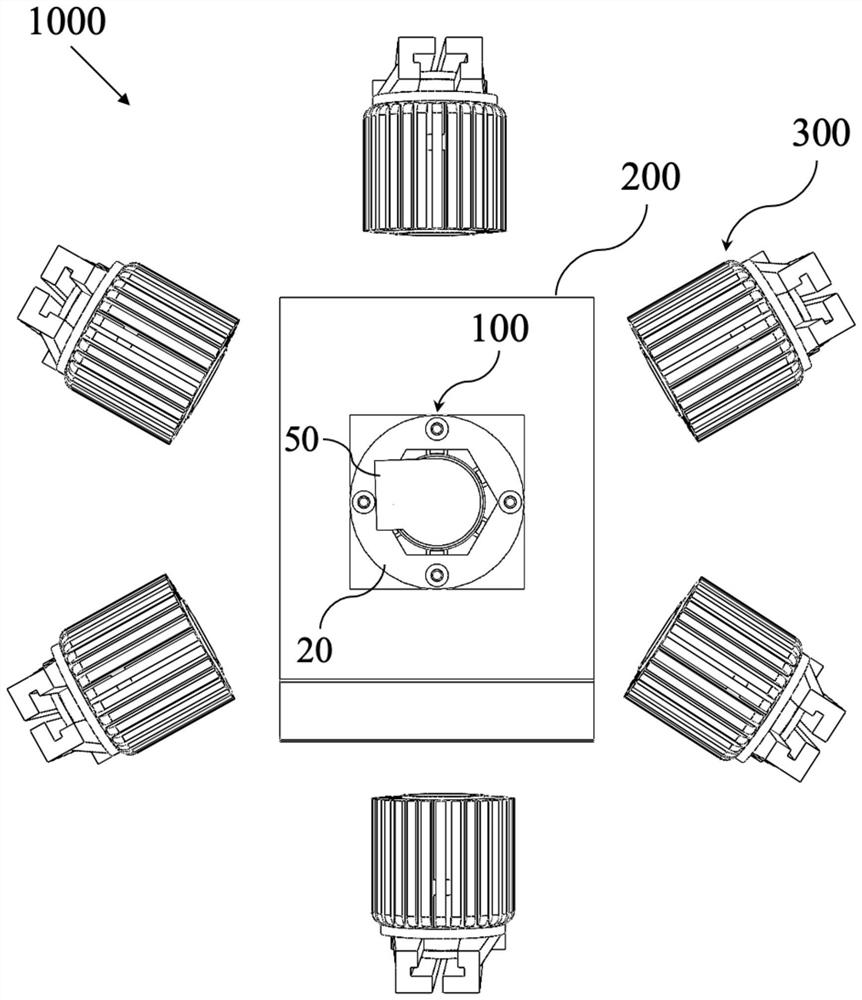

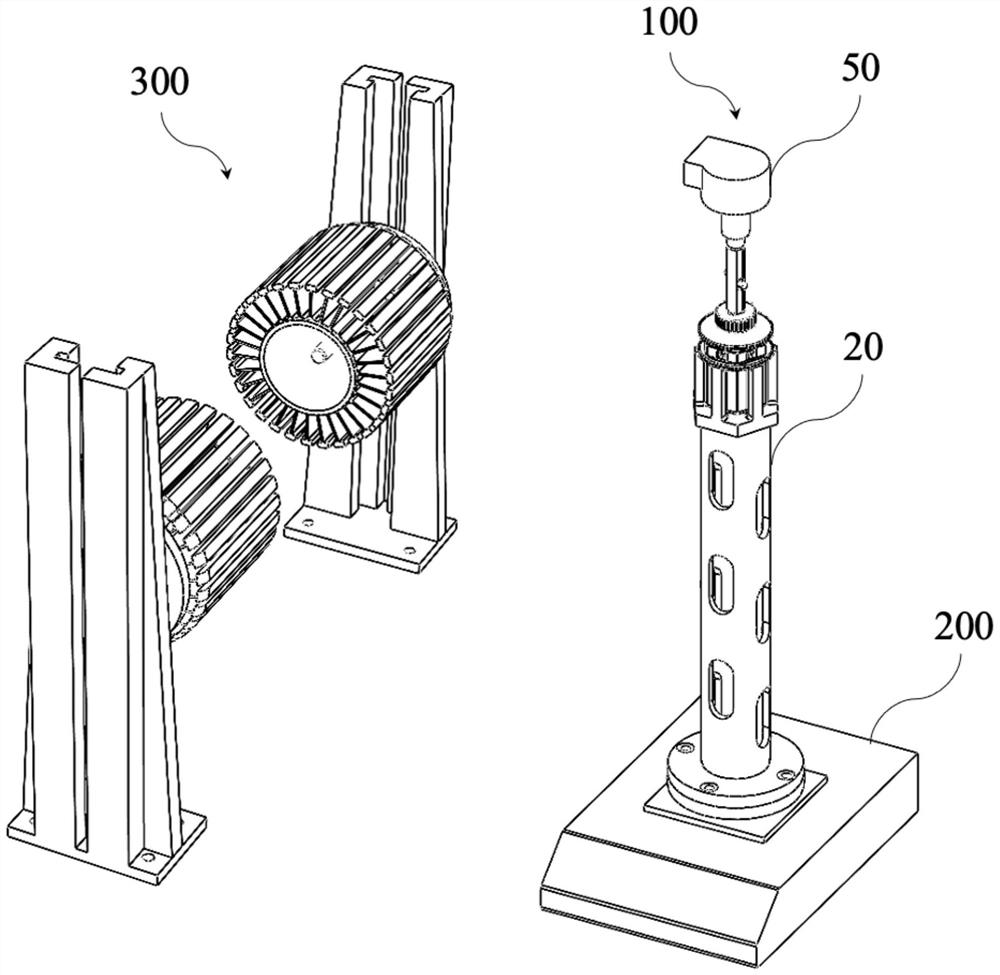

[0063] like Figures 1 to 2 As shown, the thermogravimetric automatic detection system 1000 includes a thermogravimetric automatic detection device 100, an electronic balance 200, a radiation heating device 300 and a control unit;

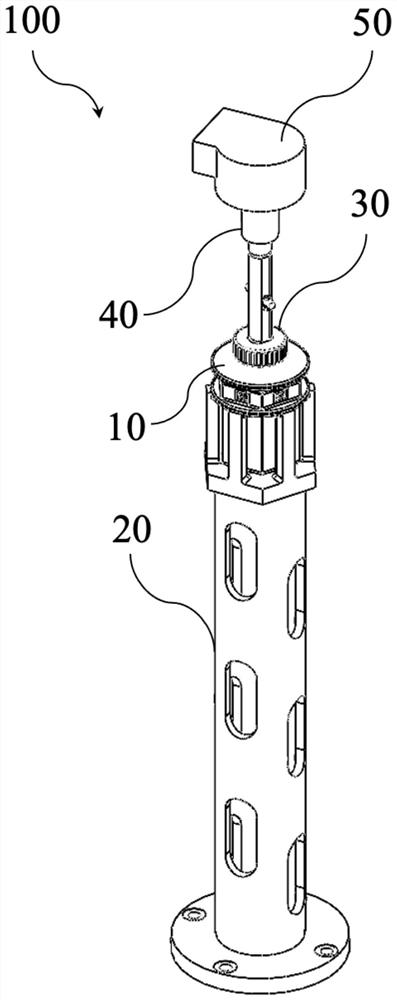

[0064] like Figures 3 to 5 As shown, the thermogravimetric automatic detection device 100 includes a crucible 10 , a supporting member 20 , a crucible connecting member 30 , a telescopic driving member 40 , a rotating member 50 and a side pressure sensor 60 .

[0065] like Figures 4 to 6 As shown, the crucible 10 includes a crucible cover 11 , a crucible base 12 and a limiting bracket 13 .

[0066] The crucible cover 11 includes a cover body 11a and two positioning pins 11b (limiting protrusions). The cover body 11a includes an upper cover part 11a-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com